日本電気硝子:次世代・全固体ナトリウム電池:実用レベルの性能確認(動画):

Nippon Electric Glass:All-solid-state sodium ion battery: Performance confirmation of practical level:

日本电动玻璃:下一代全固态钠离子电池:实用水平的性能确认

日本電気硝子:

6月12日、次世代電池「全固体ナトリウムイオン電池」で、「取り出す電流を、従来の20倍に高めた」と発表した。

「正極に使うガラス材料の粒を、小さくするなど材料を工夫」により、電流が流れを向上させた。

車載向けに応用できる。

2025年目標に量産体制を整え実用化を目指す。

全固体ナトリウムイオン電池:

現在、普及しているリチウムイオン電池より、安全性が高い。

材料となる資源が豊富なため、コストが下がる見込み。

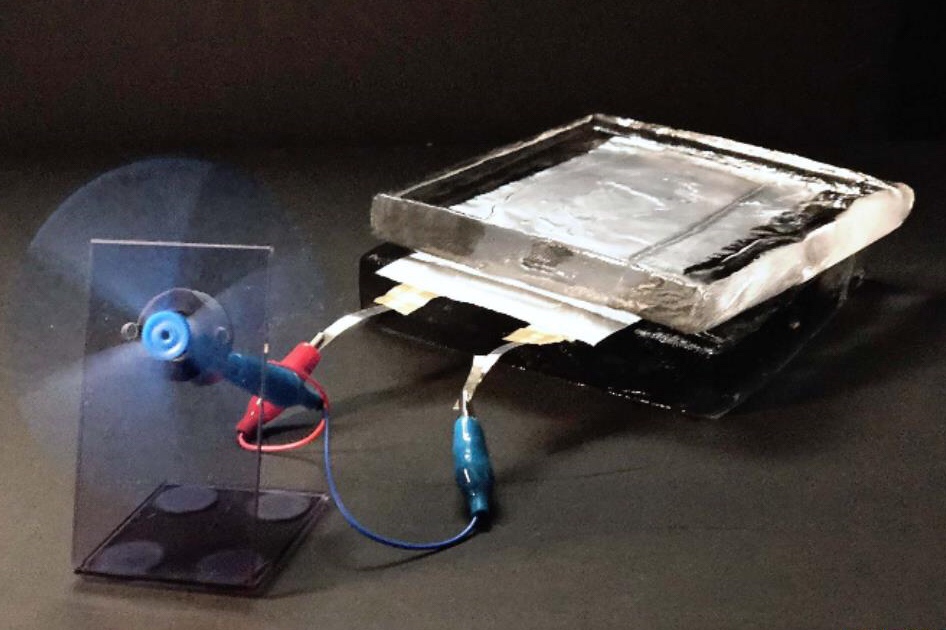

小型のモーターを使った実験では、「低温でも性能を落とさず、充放電ができること」を確認した。

日本経済新聞

https://r.nikkei.com/article/DGXMZO60309260S0A610C2LKA000?s=4

Nature Research 社が発行する Scientific Reports に全固体二次電池の論文が掲載

https://www.neg.co.jp/uploads/news_20200612_jp.pdf

Paper on all solid state secondary battery appears in Scientific Reports – Nature

https://www.neg.co.jp/uploads/sites/2/news_20200612_en.pdf

Enhanced rate capabilities in a glass-ceramic-derived sodium all-solid-state battery

Published: 11 June 2020

Hideo Yamauchi, Junichi Ikejiri, […]Takayuki Komatsu

Scientific Reports volume 10, Article number: 9453 (2020) Cite this article

Abstract

An all-solid-state battery (ASSB) with a new structure based on glass-ceramic that forms Na2FeP2O7 (NFP) crystals,

which functions as an active cathode material, is fabricated by integrating it with a β″-alumina solid electrolyte.

Two important factors

that influence the rate capability of this ASSB were optimised.

First,

the particle size of the precursor glass powder from which the NFP crystals are formed was decreased.

Consequently,

the onset temperature of crystallisation shifts to a lower temperature, which enables the softening of NFP crystals and their integration with β″-alumina at a low temperature, without the interdiffusion of different crystal phases or atoms.

Second,

the interface between the β″-alumina solid electrolyte and cathode active materials which consisted of the NFP-crystallised glass and acetylene black used as a conductive additive,

is increased to increase the insertion/release of ions and electrons from the active material during charge/discharge processes.

Thus, the internal resistance of the battery is reduced considerably to 120 Ω.

Thus, an ASSB capable of rapid charge/discharge that can operate not only at room temperature (30 °C) but also at −20 °C is obtained.

This technology is an innovative breakthrough in oxide-based ASSBs, considering that the internal resistance of liquid electrolyte-based Li-ion batteries and sulphide-based ASSBs is ~10 Ω.

Scientific Reports

https://www.nature.com/articles/s41598-020-66410-1