Showa Denko: Direct bonding of aluminum alloy and polycarbonate resin: Applicable to smartphone housings

Showa Denko:

We have developed an innovative technology that directly joins aluminum alloys and polycarbonate resins (general-purpose amorphous engineering plastics) without using adhesives.

To join aluminum alloy and resin, mechanical joining (fastening with bolts) and adhesive joining (using adhesive) are the mainstream.

Resin and metal materials: Direct bonding technology

In recent years, new technology that directly joins metal materials during injection molding of resin materials has attracted attention.

Metal resin direct bonding is a technology that is expected to have advantages such as simplified processes, high productivity, and the ability to process even complex shapes.

Conventional technology:

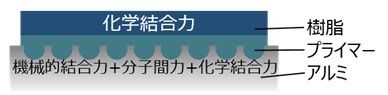

The conventional metal resin / direct bonding technology relies on mechanical bond strength (resin injection on the metal surface: anchor effect).

Bonding with amorphous engineering plastic (polycarbonate resin) was considered difficult.

New Technology: ‘Aluminum Alloy and Polymer Chemistry Knowledge’

We made use of the knowledge of aluminum alloys and polymer chemistry cultivated over many years.

Uses aluminum alloy with special surface treatment and primer treatment.

This realizes direct bonding with polycarbonate resin.

Our joining technology is an epoch-making joining method that has not only the anchor effect but also chemical bond strength (Note 1).

This technology has a bonding strength of 25MPa (megapascals) or more under polycarbonate resin molding conditions.

No special conditions or incidental facilities are required to develop the bonding strength.

This technology can join polycarbonate resin and aluminum which is a lightweight metal.

In the future, it can be applied to smartphone housing applications.

News Release | Showa Denko KK