Semiconductor Equipment in China: Technology Level of Exposure Process

ーExport restrictions on Japanese DUV exposure equipmentー

ー ArFi Immersion Lithography Achieved in China ー

We will deliver the summary from the Yahoo article.

Level of exposure process:

China’s weakest point in semiconductor manufacturing is exposure equipment, which is centered on lithography technology.

What is the exposure process:

Semiconductors have extremely fine wiring drawn on small chips.

Making a wiring pattern by “light irradiation” is called an exposure process.

Japan’s export restrictions started:

Japan implemented semiconductor export controls on July 23rd.

It is truly centered on exposure equipment and processes.

Export of ASML to China:

More than 80% of the world’s major semiconductor manufacturers are ASML customers.

Exports to China account for 15% of the world total.

Traditionally, China and ASML have been on very good terms.

US sanctions against China:

The United States has asked the Netherlands to impose new restrictions on exports of semiconductor equipment to China.

The ASML has been forced into a position of reluctance to align itself with the United States.

It currently accounts for 34.7% of the global market.

ASML’s business locations:

In 2020, we established our own business base in Wuxi High-Tech Park, Jiangsu Province.

ASML has independently developed DUV (deep ultraviolet) exposure equipment for China.

They were planning to launch it in mainland China.

US and Dutch Governments:

In June 2023, the Netherlands decided to ‘enforce the export control law from September 1st’.

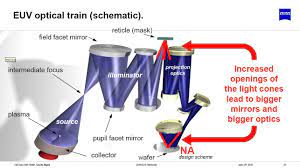

The target of this regulation is limited to a small number of high-end DUV and EUV lithography equipment.

ASML leaves “the possibility of releasing a China-only version in China.”

China resents that “ASML is also a victim of the United States.”

History of the five generations of light sources:

Based on the history of five generations of light sources, China’s development level is analyzed.

g-line: long-wavelength type used in the 1980s

i-line: A slightly shorter wavelength type used in the 1990s

KrF: Krypton-fluorine laser light in the late 1990s

ArF: Laser beam with argon fluoride

EUV: The latest version among the 5 generations

Chinese light source development:

China has successfully developed a light source equivalent to the fourth and a half generation of ArFi.

Chinese Academy of Sciences, Changchun Optical Institute, and Harbin Institute of Technology have successfully developed a 12w DDP-EUV.

The “i” in ArFi stands for “immersion.”

Objective lens development:

The optical system is one of the major components of exposure equipment.

ASML objective lens:

ASML exclusively uses German Zeiss lenses.

Japanese objective lens:

Canon and Nikon have their own lenses. It is advantageous as an optical manufacturer.

Chinese objective lens:

90nm was developed by “Changchun Apu Optical Technology Co., Ltd.”.

“Changchun Optics Office” is developing 32nm EUV lenses.

However, the gap with Zeiss is large.

Dual wafer stage system:

Two wafers can be handled at the same time in one exposure system.

A system that simultaneously performs exposure and measurement.

In Chinese, it is written as “Shuanggutai”.

China’s “shuangtai”:

Tsinghua University and Huazhuo Precision Medicine) achieved 10nm (movement accuracy).

By the way, ASML has been realized down to 2nm.

Level of immersion exposure system:

We have developed an immersion exposure system that uses a light source with a short wavelength.

ArF immersion lithography and EUV lithography are what we arrived at.

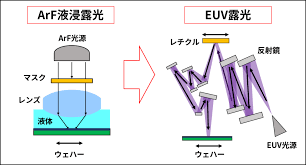

What is ArF immersion exposure:

An “ArF light source” with a wavelength of 193 nm is used as the light source.

With this technology, patterns can be formed with processing accuracy of the 10-nano generation.

。

Zhejiang Qier Mechatronics:

Zhejiang Qier Mechatronics in China has succeeded in realizing ArFi immersion lithography.

ASML is ahead of China in EUV exposure.

China competes in power semiconductors:

The United States has strengthened sanctions against China in high-end semiconductor manufacturing.

China, on the other hand, will shift to manufacturing middle-class semiconductors with large line widths.

In addition, power semiconductor manufacturing will be strengthened.

Chinese power semiconductors:

In 2020, China’s IGBT (Insulated Gate Bipolar Transistor) self-sufficiency rate was 20%.

By 2024, the self-sufficiency rate is expected to reach 40%.

Effectiveness of US sanctions:

China has already surpassed the United States in space development.

America’s sanctions diplomacy with China has an expiration date.

https://news.yahoo.co.jp/expert/articles/6a65579cd968bf1688062a18f07c0d2e0d6262c1