Japan: Semiconductor manufacturing equipment and materials (pre-process): Share ranking

Semiconductor manufacturing equipment and materials:

Japan has a very high market share in the fields of semiconductor manufacturing equipment and materials.

Why is this?

A comparative analysis was made with “fields with a high market share of Western manufacturers”.

SEMICON JAPAN 2021 Hybrid

Semi Technology Symposium

Friday, December 17th

At the Advanced Materials / Structure / Analysis Session, We will give a lecture entitled “Competitiveness of Japanese Equipment and Materials and Their Sources”.

The framework is as follows.

Equipment and materials

Analysis of Japan share

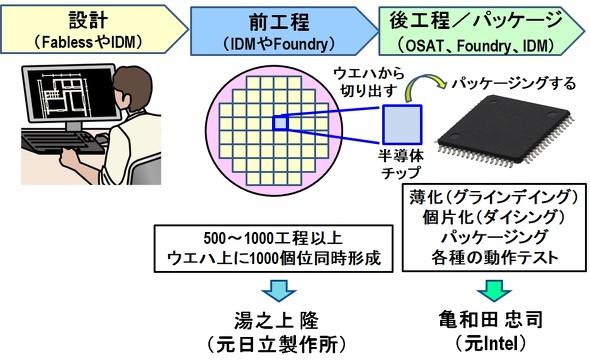

In the pre-process and post-process / package,

Clarify “Japan’s share of equipment and materials”.

Analyze and consider “why a certain device or material has a high market share “.

Pre-process equipment and materials:

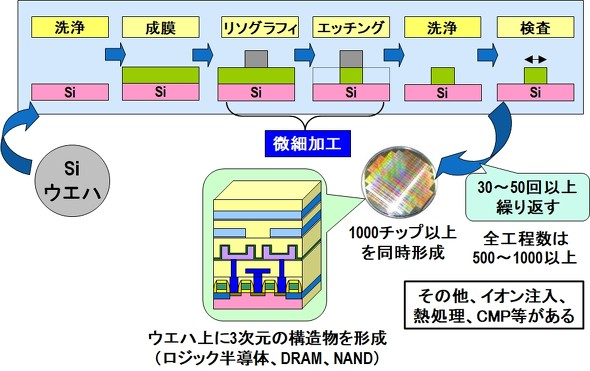

The pre-process can be 500 to 1000 processes, but the process is simple (Fig. 2).

A silicon wafer with a diameter of 200 to 300 mm is used for the substrate.

Cleaning → Film formation → Patterning by lithography → Etching → Ashing and cleaning → Inspection

Repeat the fixed process 30 to 50 times or more. (Other processes such as ion implantation, heat treatment, and CMP)

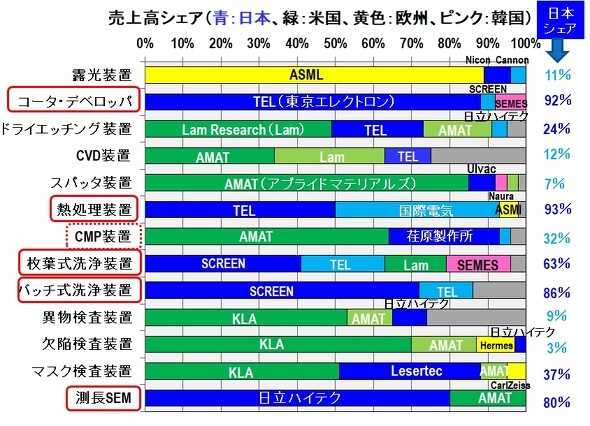

Share of front-end manufacturing equipment by company:

Figure 3 shows the market share of the main manufacturing equipment used in this pre-process by company.

The high market share of Japanese equipment is

Coater / Developer (92%),

Vertical diffusion furnace heat treatment equipment (93%),

Single-wafer cleaning device (63%),

Batch type cleaning equipment (86%),

Length measurement SEM (80%), etc.

CMP equipment does not have the top share.

However, Ebara Corporation has a 30% share of logic semiconductors.

This is also counted as a device with a high share.

On the other hand, Japan’s share of exposure equipment, dry etching equipment, film formation equipment such as CVD and sputtering, and various inspection equipment is low.

However, many Japanese parts and equipment are used in these devices. It was

Among them, quartz parts and ceramic parts are overwhelmingly made in Japan.

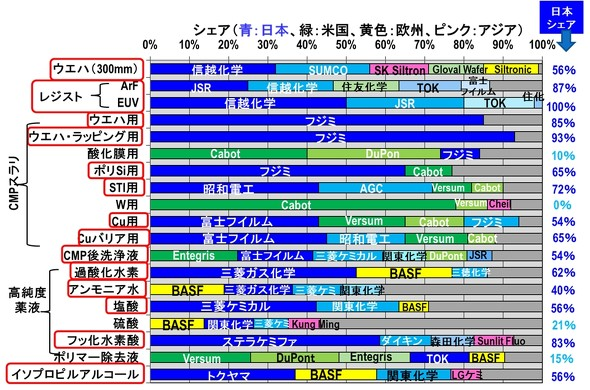

Share of front-end materials by company:

Next, Fig. 4 shows the market share of the main materials used in the front-end process by company.

Silicon wafer,

Various resists,

Various CMP slurry,

Various high-purity chemicals, etc.

It can be seen that there are a large number of materials with a high market share in Japan.

Presence of Japanese material manufacturers:

Japanese material manufacturers have a stronger presence than equipment manufacturers.

In this way, there are devices in Japan that have a characteristically high market share.

Even with equipment with a low market share, many parts and equipment are made in Japan.

In addition, Japan has a high market share for most materials.

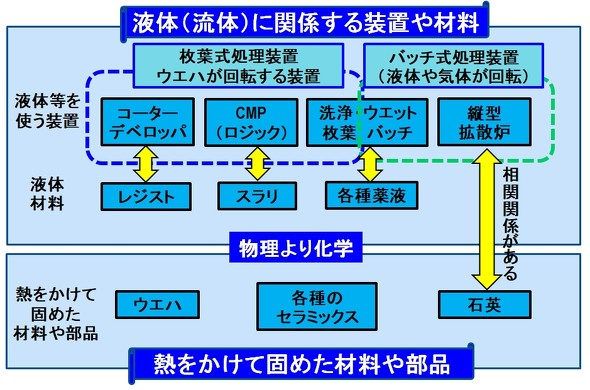

Classification of equipment, materials and parts:

We classified the high and low shares of Japan.

Figure 5 shows the classification of those with a high market share in Japan.

There are two points. It was

First,

The market share of liquid-related equipment and materials is high.

Second,

It has a high market share of materials and parts that have been hardened by heating.

Classify the first

It can be further divided into two categories.

one:

“A single-wafer rotating device and the liquid material used for it”.

In particular,

Coater / Developer and Resist,

CMP (for logic) and slurry,

A single-wafer cleaning device and various chemicals.

Yellow arrows indicate that there is a correlation.

the other is:

It is a “device that circulates (rotates) liquids and gases inside the device”.

It is a “batch type cleaning device and vertical diffusion furnace”.

Vertical diffusion furnace:

Many quartz parts are used in this vertical diffusion furnace.

Quartz parts

This quartz part has an overwhelmingly high market share in Japan.

Wafers and ceramic parts

Similar ones are silicon wafers and various ceramic parts.

What they all have in common is that they are materials and parts that have been hardened by heating.

Japan is good at “chemistry rather than physics”:

We tried to classify the equipment, materials, and parts that have a high market share in Japan.

It can be said that Japan is demonstrating its strengths in the field of “chemistry rather than physics.”

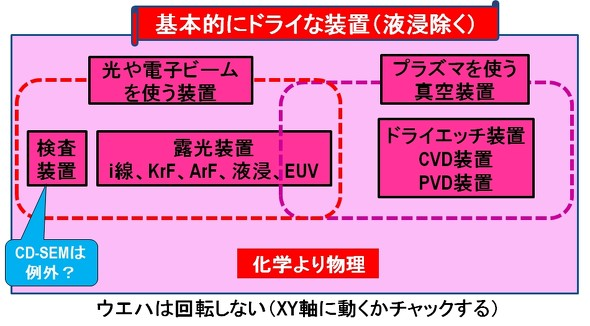

Classification of equipment with low market share in Japan:

On the other hand, Fig. 6 shows the classification of devices with a low market share in Japan.

Basically, the Japanese market share of dry equipment is low (excluding ArF immersion).

Again, there are two points.

First:

Japan’s share of optical and electron beam devices is low.

It is an inspection device and various exposure devices.

Here, CD-SEM has a high market share in Japan, so this classification is an exception.

Second:

Japan’s share of vacuum equipment that uses plasma is low.

to be specific,

Dry etching equipment,

CVD equipment,

PVD device (sputtering device).

EUV (extreme ultraviolet) exposure equipment, which is a state-of-the-art exposure equipment, also falls into this category.

It is a device that has a stronger element of “physics than chemistry” and can be said to have a low market share .

Differences in thinking between Japanese and Westerners:

Westerner’s idea:

The theory comes first in the idea of Westerners.

Discuss early in development and unify policies.

Then create standards, rules, stories, and logic.

Western engineers are clumsy with their hands and are not good at experiments.

Western engineers do not experiment at all, but leave it to the technician occupation.

Japanese idea:

On the other hand, Japanese people intuitively move their hands based on their experience to conduct experiments.

In addition, we are good at optimizing within a fixed framework.

However, I am not good at making standards and rules.

Japanese and Westerners:

Japanese and Westerners have completely different ideas and behaviors.

It can be inferred that this leads to high and low shares of equipment and the like.

Next, we will discuss post-process / packaging.

–EE Times Japan

https://eetimes.itmedia.co.jp/ee/articles/2112/14/news034.html