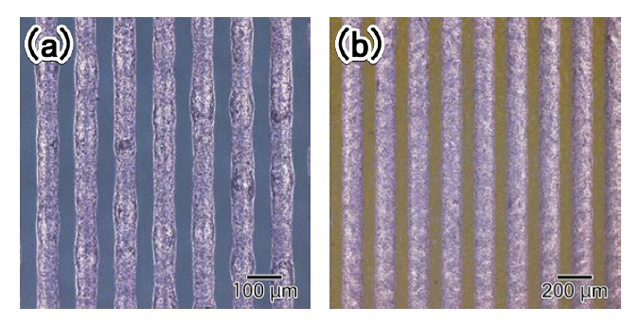

Wiring phase diagram obtained by screen-printing the developed copper nanopaste on a film and then firing at 200 ° C x 30 min. (Normal pressure firing in a nitrogen atmosphere).

(a): Wiring formation on PEN film, (b): Wiring formation on PI

Mitsui Kinzoku: Copper nanoparticles that can be sintered at low temperature: Substitute for silver paste

-New organic-free synthesis of copper fine particles-

~ Realizing a green synthetic method using water-soluble base metal salts ~

Tohoku University, Institute of Multidisciplinary Materials Science

Mitsui Mining & Smelting Research Institute

Developed “organic-free synthesis process” for “copper fine particles expected as conductive materials”.

The synthetic method developed this time:

Copper fine particles are synthesized by using a water-soluble base metal salt.

The obtained copper fine particles are

Because it does not contain organic matter

Very little gas is generated when firing

It was confirmed that it sinters at low temperature.

Innovative synthesis technology:

This method is

It can be expected as an “innovative synthetic technology for the realization of a sustainable society”.

In addition,

It is possible to create metal fine particles with new functions that have never been seen before.

This result:

It was published in nature.com’s open access electronic journal “Scientific Reports” on December 20th. (DOI: 10.1038 / s41598-021-03707-9)

Summary of announcement:

Organic Free Copper Particle Synthesis Process

(Copper precursor wet reduction method)

We have newly developed an organic-free copper particle synthesis process.

Using base metal salt,

Underwater, under the atmosphere, at room temperature

Under low environmental load conditions

Copper fine particles can be synthesized.

Resource-saving and energy-saving synthesis method:

Compared to the conventional method that uses organic matter, it is a resource-saving and energy-saving synthesis method.

Conductive materials for next-generation electronics:

Synthetic copper fine particles do not contain organic substances.

Therefore, there is very little gas generation when firing.

The application of next-generation electronics as a conductive material can be expected.

【Overview】

Copper fine particles are richer in elements and cheaper than precious metal fine particles such as gold and silver.

It has the same high conductivity and thermal conductivity as precious metals.

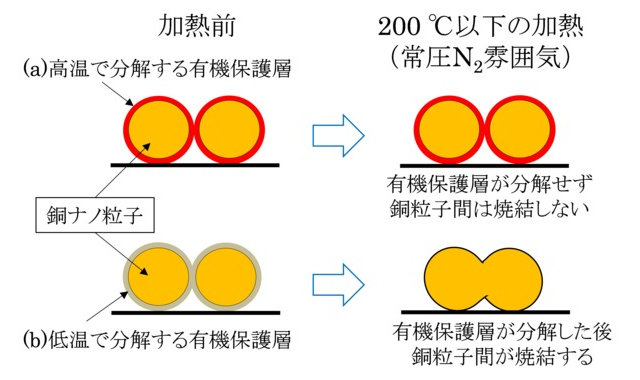

Previous copper particle synthesis method:

However, in the conventional copper particle synthesis method, organic substances are added and used, and their decomposition treatment is required.

Mitsui Kinzoku and Tohoku Univ./Development of “Low Temperature Sinterable Copper Nanoparticles” / Expectations for Alternative from Silver Paste | Nikkan Steel Newspaper Japan Metal Daily

https://www.japanmetaldaily.com/articles/-/41273

Low temperature sinterable copper nanoparticles: Synthesized under low environmental load conditions-Printed electronics and next-generation power device junctions enter the copper era-fabcross for engineers

https://engineer.fabcross.jp/archeive/190201_tohoku.html

A mild aqueous synthesis of ligand-free copper nanoparticles for low temperature sintering nanopastes with nickel salt assistance

Scientific Reports

Abstract

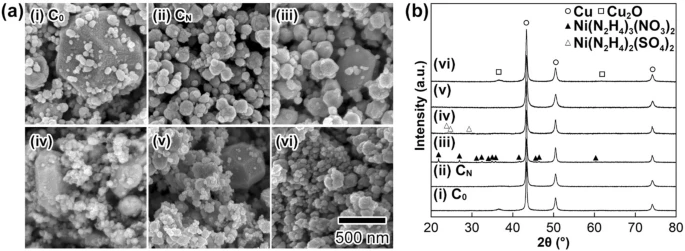

An organic ligand-free aqueous-phase synthesis of copper (Cu) nanoparticles (NPs) under an air atmosphere

was successfully achieved by reducing copper(II) oxide particles with a leaf-like shape in the presence of Ni salts at room temperature.

The resulting Cu NPs with a mean particle diameter of ca. 150 nm

exhibited low-temperature sintering properties due to their polycrystalline internal structure and ligand-free surface.

These Cu NPs

were applied to obtain Cu NP-based nanopastes with low-temperature sintering properties,and the resistivities of the obtained Cu electrodes after annealing at 150 °C and 200 °C for 30 min were 64 μΩ∙cm and 27 μΩ∙cm, respectively.

The bonding strength between oxygen-free Cu plates prepared using the Cu NP-based nanopastes

reached 32 MPa after pressure-less sintering at 260 °C for 30 min under a nitrogen atmosphere.

The developed manufacturing processes using the developed Cu nanopastes

could provide sustainable and low-CO2-emission approaches

to obtain Cu electrodes on flexible films and high-strength bonding between metal plates as die-attach materials for power devices under energy- and resource-saving conditions.