Taiyo Nippon Sanso: Copper nanoparticles, sheet-like bonding material : For SiC / GaN power devices

2020/01/28 News Release

Taiyo Nippon Sanso: Copper nanoparticles

Taiyo Nippon Sanso has succeeded in developing “sheet-shaped bonding materials for next-generation power devices such as SiC and GaN”.

High strength and high reliability have been achieved by using copper nanoparticles as the sheet-like joining material.

Power Devices: Current Issues

Power devices are used in semiconductor devices (inverters / converters) for power converters in EVs and PHVs.

In order to increase the efficiency of power devices, it is necessary to reduce the size of the module and increase the output power density by increasing the operating temperature limit.

Conventional: Si power device / heat resistance problem

However, in Si power devices, the problem of “operating temperature is 150 ° C and heat resistance” has reached the limit of miniaturization.

On the other hand, SiC / GaN device materials can operate at 200 ° C, and are expected to replace Si power devices.

Conventional: bonding materials / “solder-based materials” / heat resistance problems

Conventionally, “solder-based materials” have been used as bonding materials for Si power device electronic components.

However, solder-based materials have poor heat resistance and are not suitable for SiC power devices that are expected to be used in high-temperature environments.

In addition to “solder-based materials,” a bonding material that can withstand high-temperature operation was required.

This time: Attention as metal nanoparticles / substitute candidate materials

Metal nanoparticle is attracting attention as an alternative candidate material for power device bonding materials such as SiC.

Copper nanoparticles are particularly expected from the viewpoint of ion migration * 1 resistance and manufacturing cost.

This time: Copper nanoparticles: sheet-like joining material

Taiyo Nippon Sanso / With proprietary technology,

Making full use of oxygen combustion technology,

The copper nanoparticles are covered with a sub-oxide layer with a particle diameter of 100 nm / surface several nm,

We have a dry mass production technology.

This time: Development process

The process / synthetic particles can be fired at 150 ° C at low temperature in a reducing atmosphere. * 2

A small amount of a reducing agent is added to the binderless / copper nanoparticles, and the bonding layer structure is optimized.

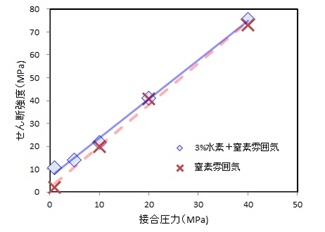

Joining without pre-drying in a nitrogen atmosphere without adding reducing gas such as hydrogen (Fig. 1)

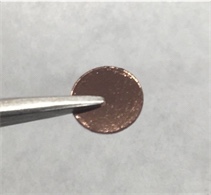

We have developed “Sheet bonding material with high bonding strength and excellent reliability (Photo 1)”.

Samples in which this bonding material was used to bond SiC and a copper plate were confirmed to have no interfacial delamination even in a heat cycle test of more than 1,000 times, ensuring high reliability.

News / Notices | Taiyo Nippon Sanso Corporation

http://www.tn-sanso.co.jp/jp/news/detail.html?id=3622