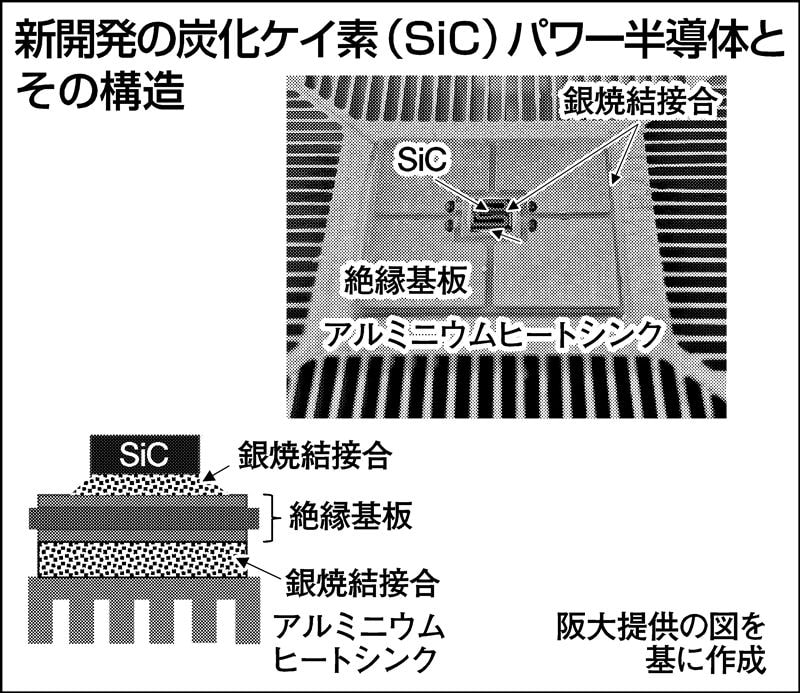

Osaka Univ: Ultra-low thermal resistance SiC power module: Silver sintered joining tech

Osaka University F3D Implementation Collaboration Research Institute

Yamato Science

We have developed an ultra-low thermal resistance SiC power module using our proprietary silver sintering and joining technology.

The temperature of the joint

From 270 degrees C of conventional solder joint

It dropped to 180 degrees C.

It is expected to be applied in fields that require high heat resistance and high reliability, such as automobiles and IoT devices.

Silver sintered joining technology:

SiC and insulation board,

Aluminum heat sink,

Directly bonded by low temperature and low pressure silver sintering.

Conventional problems:

The thin film such as nickel on the aluminum surface, which was conventionally required for solder bonding, is no longer required.

This solution:

The thermal resistance is reduced to about half, heat dissipation is not hindered, and the manufacturing cost is reduced.

Large area bonding is possible even for complicated shapes such as heat sinks that cannot be bonded under pressure.

High output density and easy to compact and lightweight.

Characteristics of SiC semiconductors:

The SiC semiconductor can operate even at a high temperature of 250 ° C. or higher.

Energy loss is also small

Cars, railroads, etc.

There is demand for industrial robots.

Conventionally, heat dissipation is a problem:

Until now, “bonding using solder or grease” has been “the problem of thermal resistance”.

This time, heat dissipation is improved:

If the heat dissipation is improved, it will lead to the reduction of CO2 emissions and contribute to the SDGs of the United Nations.

It is expected to be used in post-fifth generation communication (6G) communication and the aerospace industry.

New switch