Iwatani Sangyo: A new catalyst for decomposing volatile organic compounds (VOC)-rare metals such as La and Co

Realizing low cost and high durability by not using precious metals

Iwatani Industry

Osaka University

2019/05/24

As a catalyst for decomposing volatile organic compounds (VOCs), we developed a new catalyst with high thermal durability without using platinum or other precious metals.

This helps reduce the cost of installing VOC purification equipment and the cost of maintaining the catalyst.

Current problems: decomposition of volatile organic compounds (VOCs)

Currently, platinum and other precious metal catalysts are widely used.

However, in addition to the high cost of precious metal catalysts, there is a problem that the catalyst performance is gradually deteriorated due to poisoning by impurities (such as sulfur).

These poisoning components are removed by heat treatment of the catalyst at high temperature.

However, when noble metals are subjected to high-temperature treatment, the surface area decreases and the catalytic activity decreases due to the progress of interparticle sintering and grain growth.

Catalyst developed this time: No precious metals

The newly developed catalyst does not use precious metals.

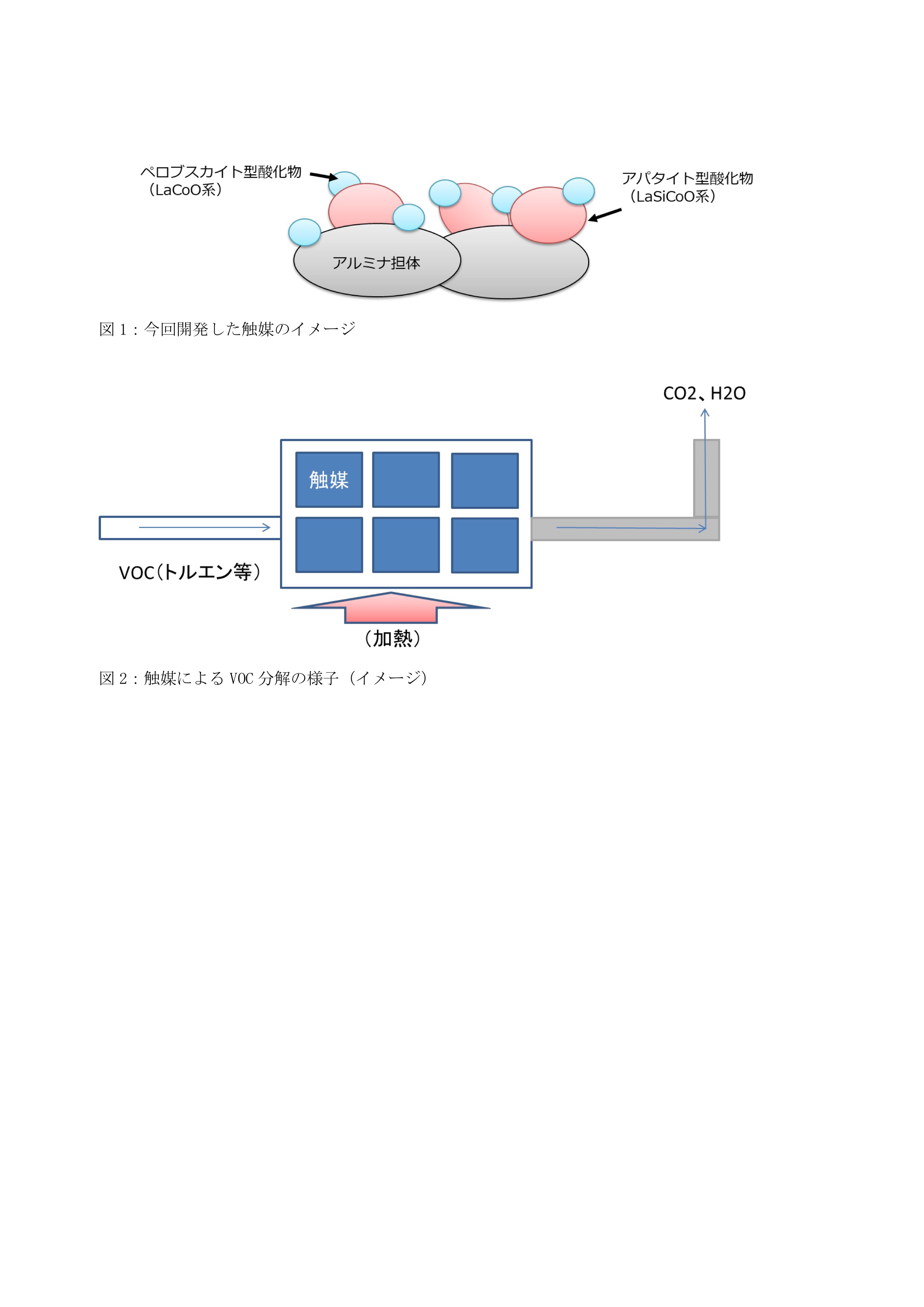

Catalyst active species: Perovskite-type oxide (LaCoO system),

Promoter: Apatite-type oxide (LaSiCoO-based) is selected.

Cost is lower than precious metal catalysts.

High temperature durability is high for both catalytically active species and promoters.

Even when poisoned by sulfur etc., poisoned components can be removed by high temperature heat treatment, and catalyst can be regenerated.

As a result, the initial introduction cost of the VOC purification system can be reduced, and the catalyst activity can be recovered only by high temperature treatment.

By doing this, you can expect to reduce maintenance costs.

Iwatani Industry:

We use rare earth elements such as La (lanthanum) and rare earth elements such as Co (cobalt) that are used in this invention.

We handle metal raw materials widely.

At present, we are focusing on the technologies possessed by Osaka University while developing applications for these raw materials.

In the future, we will utilize our gas analysis technology and jointly develop a business with a catalyst manufacturer.

http://www.iwatani.co.jp/img/jpn/pdf/newsrelease/1326/190524_news_jp1.pdf