The Univ of Tokyo: Femtosecond laser emits extreme ultraviolet light: Processing metal nanoparticle resist thin film

–The forefront of microfabrication, which opens up the diffraction-limited focusing of extreme ultraviolet light-

The University of Tokyo: Research Group

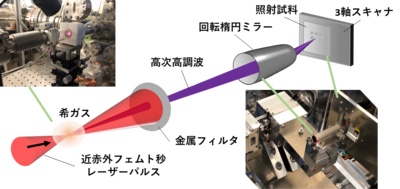

Extreme ultraviolet light was generated as a high-order harmonic of femtosecond laser light in the near infrared region.

Focusing the extreme ultraviolet light to the diffraction limit,

By irradiating the sample,

Realized fine processing on the sub-micrometer scale.

Laser processing:

In laser processing, “how finely it can be processed” is the biggest issue.

The shorter the wavelength of light, the smaller the size of the diffraction limit, which is suitable for microfabrication.

Near infrared region: femtosecond laser

By “focusing a femtosecond laser in the near infrared region on a medium such as a rare gas,”

It is possible to “generate ultra-short pulsed light in the extreme ultraviolet region as high-order harmonics”.

Therefore, high-order harmonics in the extreme ultraviolet region have been attracting attention as an effective light source for fine processing.

Concentration of extreme ultraviolet light: current problems

However, it is not possible to use a transmissive lens that uses the refractive index to collect extreme ultraviolet light.

You have to use reflective optics.

Furthermore, due to the short wavelength, it is not possible to achieve diffraction-limited focusing unless the surface accuracy of the reflective optical element is extremely high.

Until now, it has been considered difficult to perform microfabrication using high-order harmonics in the extreme ultraviolet region.

High-precision spheroidal mirror: solving the problem

We have overcome this problem with our highly developed highly accurate spheroidal mirror with a high numerical aperture.

We have succeeded in microfabrication of thin film samples using extreme ultraviolet/higher-order harmonics that are focused to the diffraction limit.

Processing steps:

Focus near-infrared/femtosecond laser pulse on argon gas,

High-order harmonics in the extreme ultraviolet region (wavelength about 32 nm). Raises,

Converging to sub-micrometer diameter by spheroidal mirror,

We processed acrylic resin (PMMA) thin film and metal nanoparticle resist thin film.

Evaluation by microscopic Raman spectroscopy:

The processed area was evaluated by Raman spectroscopy.

Clarified the “microscopic change in crystal structure in the thin film” that “chemical bonds are broken in the PMMA thin film during processing”.

Significance of this study:

If you use high-precision reflective optics to collect high-order harmonic light in the extreme ultraviolet range,

It became clear that “fine processing in the sub-micrometer range is possible.”

This achievement greatly expands the possibility of fine processing by laser.

It is expected to be applied to future fine processing processes.

The results were published on May 14, 2020 (US time) in the American scientific journal “Optics Letter.”

https://www.t.u-tokyo.ac.jp/soe/press/setnws_202005181544512389370120.html

OSA | Surface processing of PMMA and metal nano-particle resist

by sub-micrometer focusing of coherent extreme ultraviolet high-order harmonics pulses

Abstract

We demonstrate sub-micrometer processing of two kinds of thin films,

polymethyl methacrylate (PMMA) and metal nano-particle resist,

by focusing high-order harmonics of near-IR femtosecond laser pulses in the extreme ultraviolet (XUV) wavelength region (27.2–34.3 nm) on the thin film samples using an ellipsoidal focusing mirror.

The ablation threshold fluences

for the PMMA sample and the metal nano-particle resist per XUV pulse obtained by the accumulation of 200 XUV pulses

were determined to be 0.42mJ/cm2 and 0.17mJ/cm2, respectively.

The diameters (FWHM) of a hole created by the ablation on the PMMA film at the focus

were 0.67 µm and 0.44 µm along the horizontal direction and the vertical direction, respectively.

The fluence dependence of the Raman microscope spectra of the processed holes on the PMMA sample

showed that the chemical modification, in which C=C double bonds are formed associated with the scission of the PMMA polymer chains, is achieved by the irradiation of the XUV pulses.

https://www.osapublishing.org/ol/fulltext.cfm?uri=ol-45-10-2926&id=431803

Tokyo Universities collect extreme ultraviolet light and succeed in microfabrication-EE Times Japan