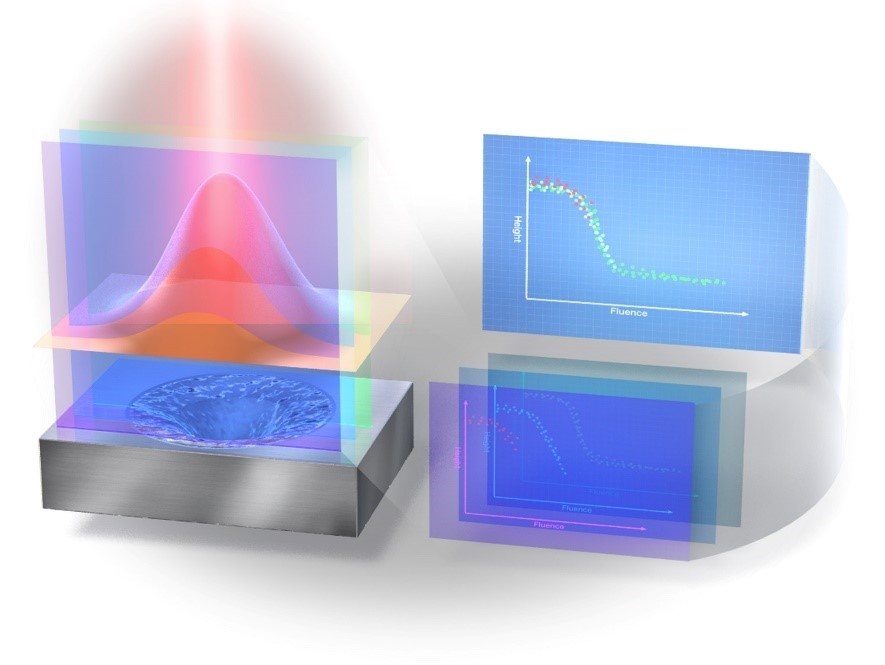

Measuring holes. (Lower left) The laser makes a hole in a material. (Upper left) The fluence of the laser is measured. (Lower right) Measurements of the fluence and the hole depth are superimposed. (Upper right) The relationship between these measurements is then determined so that hole depth can be calculated based solely on the fluence. © 2021 Sakurai et al.

The University of Tokyo: Laser fluence map method development: Elucidation of laser processing principle

University of Tokyo:

We have developed a new method for the dependence of the depth of the machined hole on the incident light intensity by irradiating with an ultrashort pulse laser.

New method (fluence map method):

Hundreds of thousands of data can be obtained at one time from only one laser machined hole.

Elucidation of the principle of laser processing:

It is essential to elucidate the principle of laser machining in order to apply it industrially as a designable and controllable technology.

Using a new method (fluence map method), we elucidated the complicated physical and chemical phenomena that occur during laser machining.

Recent research has revealed that “machine learning will be a powerful method for achieving this.”

Strength,

wavelength,

pulse width,

It is important to “collect a large amount of data such as the depth and shape of the machined hole” for the laser light conditions.

Making and measuring laser-machined holes:

Laser machining is an irreversible phenomenon.

“Making a large number of laser-machined holes and measuring them” is indispensable for elucidating the principle.

However, at the actual laser processing site, the number of experiments was limited, and it was difficult to acquire a large amount of learning data.

Analyzing local fluence:

Analyze fluence for each location within the beam spot (the energy of one light pulse divided by the area of that beam)

Pay attention to the fact that the local fluence changes continuously from zero to the peak value near the spot.

It was clarified that “the processing depth at each part of the laser machined hole” “depends on the local fluence at each part of the incident laser beam”.

This dependence is the information about “how much laser light intensity causes material destruction”.

If this is accurately grasped, it is possible to obtain “information equivalent to that in the case of making a large number of machined holes and conducting an experiment”.

OPTRONICS ONLINE

https://optronics-media.com/news/20210330/72686/

Laser lights the way

A new way to observe laser interactions could improve laser-based manufacture

March 29, 2021

Despite the enormous amount of research over the decades into lasers and their applications,

there have been few ways to accurately, efficiently, and directly observe fine details of their interactions with materials.

For the first time,

researchers have found a way

to acquire such data from a production laser using low-cost equipment that could vastly improve the accuracy of items cut or etched with lasers.

Given the ubiquity of lasers, this could have wide-ranging implications in laboratory, commercial and industrial applications.

“To measure how far into a surface a laser has cut often requires tens or hundreds of depth readings to take place.

This is a substantial barrier for fast, automated laser-based production systems,” said Professor Junji Yumoto from the Department of Physics at the University of Tokyo.

“So we have devised a new way to determine and predict the depth of a hole produced by laser pulses based on a single observation rather than tens or hundreds.

This finding is an important step forward in improving the controllability of laser processing.”

Yumoto and his team

wondered how to determine the depth of a laser hole using the minimal amount of information possible.

This led them to look at what is known as the fluence of a laser pulse, which is the optical energy the pulse delivers over a given area.

As their test laser apparatus

made a hole on sapphire, the camera recorded directly the fluence distribution of a laser pulse.

Then a laser microscope measured the hole shape.

By superimposing these two results and using some modern numerical methods,

the team produced a large and reliable data set that could accurately tell you the relation between fluence and hole depth.

“This would be correspondent with the extraction of about 250,000 data points from a single measurement,” said Yumoto.

Our new method

could efficiently provide big data for machine learning and new numerical simulation methods to improve the accuracy and controllability of laser processing for manufacture.

The University of Tokyo

https://www.u-tokyo.ac.jp/focus/en/press/z0508_00171.html

A New Way To Observe Laser Interactions Could Improve Laser-Based Manufacturing – SciTechDaily