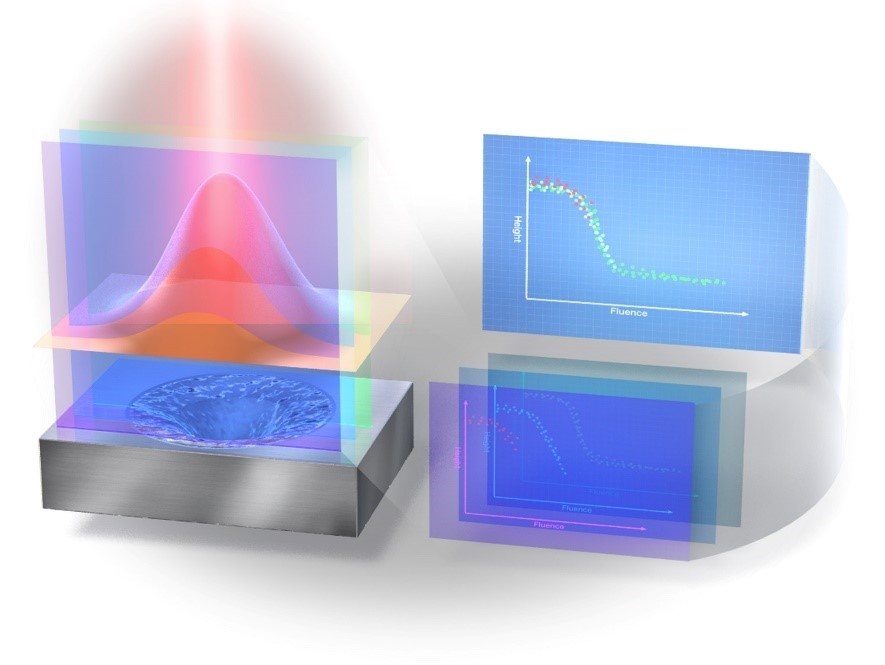

测量孔(左下)激光在材料上打孔(左上)测量激光的通量(右下)放大通量和孔深的测量(右上)然后确定这些测量值,以便仅根据注量就可以计算出孔深©2021 Sakurai等。

东京大学:激光通量图方法开发:激光加工原理的阐明

东京大学:

我们已经开发了一种通过用超短脉冲激光照射来使加工孔的深度与入射光强度相关的新方法。

新方法(通量图方法):

仅通过一个激光加工孔就可以一次获得数十万个数据。

阐明激光加工的原理:

阐明激光加工的原理对于将其作为可设计和可控制的技术进行工业应用至关重要。

使用一种新的方法(通量图方法),我们阐明了激光加工过程中发生的复杂的物理和化学现象。

最近的研究表明,“机器学习将是实现这一目标的有力方法。”

力量,

波长,

脉冲宽度

对于激光条件,“收集大量数据,例如加工孔的深度和形状”很重要。

制作和测量激光加工孔:

激光加工是不可逆的现象。

为了阐明原理,“制造大量的激光加工孔并对其进行测量”是必不可少的。

然而,在实际的激光加工现场,实验的数量是有限的,并且难以获取大量的学习数据。

分析局部通量:

分析光束点内每个位置的能量密度(一个光脉冲的能量除以该光束的面积)

注意以下事实:局部注量从零到附近的峰值连续变化。

明确了“在激光加工孔的每个部分的加工深度”“取决于入射激光束的每个部分的局部通量”。

这种依赖性是关于“多少激光强度导致材料破坏”的信息。

如果准确地掌握了这一点,则可以获得“与制造大量加工孔并进行实验的情况相同的信息”。

光学在线光学在线

https://optronics-media.com/news/20210330/72686/

Laser lights the way

A new way to observe laser interactions could improve laser-based manufacture

March 29, 2021

Despite the enormous amount of research over the decades into lasers and their applications,

there have been few ways to accurately, efficiently, and directly observe fine details of their interactions with materials.

For the first time,

researchers have found a way

to acquire such data from a production laser using low-cost equipment that could vastly improve the accuracy of items cut or etched with lasers.

Given the ubiquity of lasers, this could have wide-ranging implications in laboratory, commercial and industrial applications.

“To measure how far into a surface a laser has cut often requires tens or hundreds of depth readings to take place.

This is a substantial barrier for fast, automated laser-based production systems,” said Professor Junji Yumoto from the Department of Physics at the University of Tokyo.

“So we have devised a new way to determine and predict the depth of a hole produced by laser pulses based on a single observation rather than tens or hundreds.

This finding is an important step forward in improving the controllability of laser processing.”

Yumoto and his team

wondered how to determine the depth of a laser hole using the minimal amount of information possible.

This led them to look at what is known as the fluence of a laser pulse, which is the optical energy the pulse delivers over a given area.

As their test laser apparatus

made a hole on sapphire, the camera recorded directly the fluence distribution of a laser pulse.

Then a laser microscope measured the hole shape.

By superimposing these two results and using some modern numerical methods,

the team produced a large and reliable data set that could accurately tell you the relation between fluence and hole depth.

“This would be correspondent with the extraction of about 250,000 data points from a single measurement,” said Yumoto.

Our new method

could efficiently provide big data for machine learning and new numerical simulation methods to improve the accuracy and controllability of laser processing for manufacture.

The University of Tokyo

https://www.u-tokyo.ac.jp/focus/en/press/z0508_00171.html

A New Way To Observe Laser Interactions Could Improve Laser-Based Manufacturing – SciTechDaily