World’s highest level output: IHI’s electric turbo compressor!

-Achieves 100 kW output, 3.5 times greater than conventional products-

Report from IHI’s technical disclosure information

IHI’s electric turbo compressor:

IHI has developed an electric turbo compressor with the world’s highest level of output.

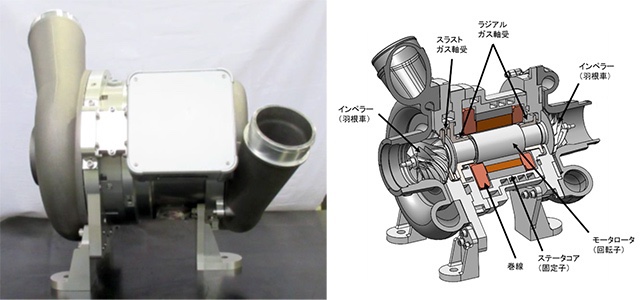

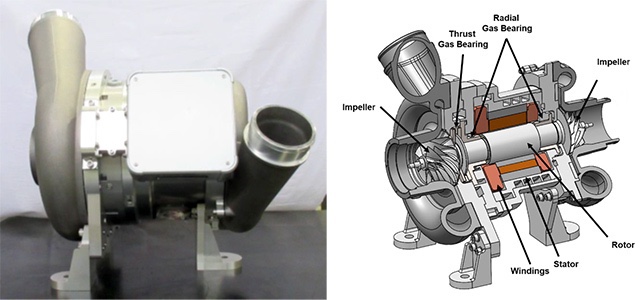

Equipped with a unique air-floating gas-bearing electric motor.

Achieved an output of 100 kW, which is 3.5 times that of conventional models.

Electric turbo compressor developed by IHI:

Used in hydrogen fuel cell propulsion systems.

It is expected to be used in hydrogen fuel cell propulsion systems for small aircraft.

A large amount of compressed air can be supplied even in thin air. Realize an airplane with a fuel cell propulsion system.

Role of electric turbo compressor:

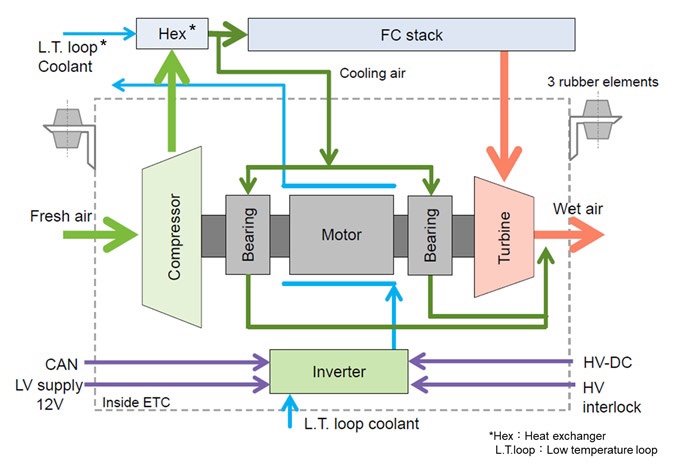

The electric turbo compressor reacts hydrogen with the fuel cell and supplies compressed air.

It supplies a large amount of compressed air to obtain high output.

The steam discharged from the fuel cell is used for power.

Applications other than fuel cell systems:

It compresses the thin outside air during flight and supplies it to the cabin air conditioner.

It is also expected to play a role in recovering energy from the compressed air in the cabin.

Developed “hydrogen conversion by electric propulsion system and on-board power generation system”.

Aiming for commercialization in the 2030s.

https://news.yahoo.co.jp/articles/87f5685be2426c4ba07d6b6a10702503938a24df

IHI Develops One of World’s Lightest and Most Compact Electric Turbo Compressors Incorporating Proprietary Air Bearing Technology that Could Help Materialize Aircraft Fuel Cell Propulsion Systems

2023FY|News|IHI Corporation

IHI’s envisioned applications for this new compressor include fuel cell propulsion systems

for small passenger aircraft, energy-efficient air conditioning in 200-seat medium-range airliners,

and in aircraft fuel cell systems, which could replace gas turbine generators to decarbonize aviation.

As part of NEDO work,

IHI endeavored to attain ultra-high speeds with a turbo compressor motor and meticulously lighten rotating parts.

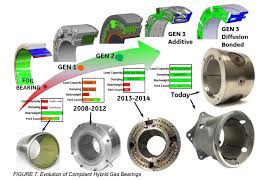

It also used a newly developed large-capacity air-floating gas bearing.

It thereby succeeded in creating an air-floating permanent magnet rotor and high-powered impeller.

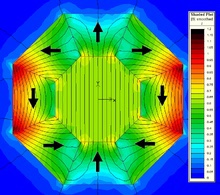

A Halbach array is a special arrangement of permanent

magnets

To achieve a compact, light, and powerful motor, IHI used a high-density magnetic array (see note 2) to maximize magnet utilization efficiency.

The array makes it possible to arrange a large number of small north-south pole magnets in a permanent magnet motor.

https://www.ihi.co.jp/en/all_news/2023/technology/1198316_3531.html