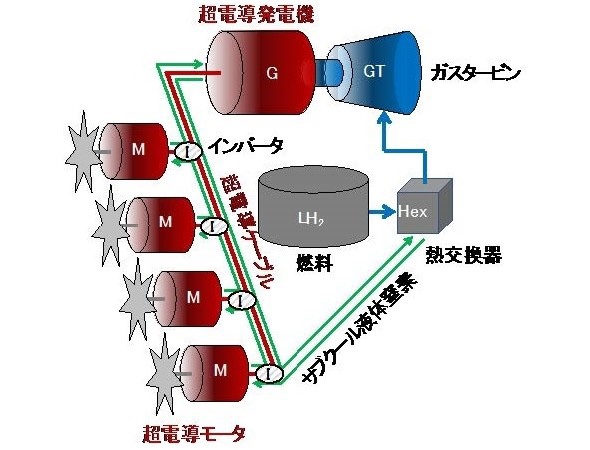

Configuration diagram of electric propulsion system Source: Kyushu University

Next-generation electric propulsion system: Successful rotation test of 400kW superconducting motor!

-Same size as conventional motors, one-tenth the weight, and twice the output-

Report based on information disclosed by Kyushu University

Kyushu University: Research Center for Advanced Electric Propulsion Aircraft

Using the latest superconducting technology, we have developed a high-efficiency, high-output all-superconducting motor.

We are entrusted with the Ministry of Economy, Trade and Industry’s NEDO project and aim to realize next-generation aircraft.

400kW class fully superconducting synchronous motor Source: Kyushu University

Successful development of all-superconducting motor:

In June 2023, we will develop a 400kW-class all-superconducting motor for electric aircraft. Successful spin test.

With full superconductivity, it is the same size as a conventional motor, weighs 1/10, and has twice the output.

On the other hand, the weak point of superconducting wires is that “AC losses peculiar to superconductivity occur under AC operation”.

Appearance of heat exchanger unit Source: Kyushu University

Overcoming the weaknesses of all superconducting motors:

The development group proceeded with “reduction of AC loss in superconducting wires and development of technology for increasing current capacity”.

Developed an “all-superconducting motor that superconducts everything”, including not only the field winding of the rotating machine but also the armature winding.

Combined with a “cooling system that circulates liquid nitrogen with a pump”, we succeeded in the world’s first rotation test.

This test result:

We will continue to develop for practical use and aim to apply it to flying cars.

This result was obtained as a result of commissioned work by NEDO.