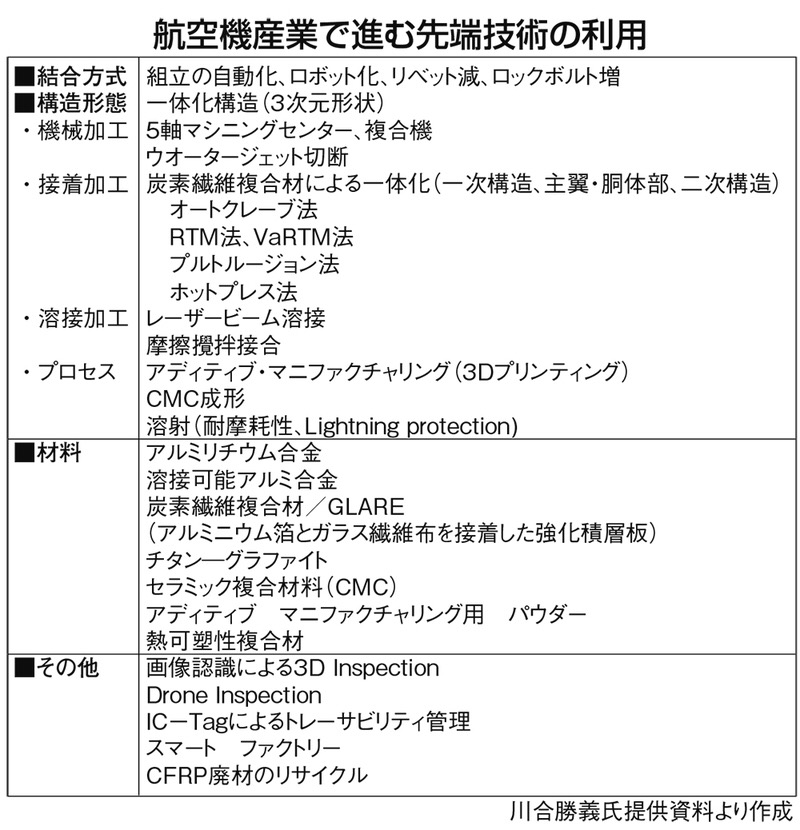

theme of the aircraft industry / advanced technology

Important keywords:

1. Coupling method: assembly automation, robotization, rivet reduction, increase in lock bolt

2. Structure type: Integrated structure (three-dimensional shape)

-Machining: 5-axis machining center, complex machine, water jet cutting

-Bonding: Integration with carbon fiber composite (primary structure, wing and fuselage, secondary structure)

-Bonding: Autoclave method, RTM method, VaRTM method, pull torque method, hot press method

-Welding process: Laser beam welding, friction welding

-3D printing: CMC molding: thermal spraying (abrasion resistance, Lightning protection)

3.Material 1: Aluminum lithium alloy, weldable aluminum alloy

3. Material 2: Carbon fiber composite material / GLARE (reinforced laminated board in which aluminum foil and glass fiber cloth are bonded)

3.Material 3: Titanium-Graphite

3.Material 4: Ceramic composite material (CMC)

3.Material 5: Powder for Additive Manufacturing

3. Material 6: Thermoplastic composite

4. Others: 3D Inspection, Drone Inspection, IC-Tag, SmartFactory, recycling of CFRP

Aircraft industry: Trends in Japan’s advanced technology : Boeing / Airbus competition intensifies

Boeing Airbus: Intensifying competition for orders

Now, competition among supply chains supporting the aircraft industry is increasing.

In the next 20 years, air passenger demand is expected to increase by an average of 4.5% annually, delivering 33,000 aircraft.

In the future, the trend for small and medium-sized aircraft will continue.

US Boeing: In January, the number of civilian aircraft announced announced reached 806 aircraft (763 in 2017), the highest ever.

France Airbus: The Bombardier small aircraft is under its umbrella, delivering the largest ever 718 aircraft.

As for Boeing, the small model “737 MAX” has fallen due to a crash and has not been delivered.

This year’s figures are expected to be greatly affected.

In the fierce competition between the two companies, sales prices have been declining.

This has led to strong cost reduction requests to cooperating companies, and Japanese companies are being urged to respond.

Metal · 3D printer: Metal additive manufacturing technology

Additive manufacturing method using metal and 3D printer.

Verification is in progress at each company to establish a production system.

Titanium aluminum and heat-resistant alloy: Processing of new alloy

Processing technology for difficult-to-cut materials such as lightweight titanium aluminum and heat-resistant alloy is required.

Japanese SMEs are proposing stable processing technology.

Alliance in Advanced Technology: Case Studies

Horiguchi Engineering: Large Jack Test Building (Photo)

Horiguchi Engineering is working with overseas engine and maintenance equipment manufacturers to increase their presence.

In April, a dedicated jack test facility for lifting aircraft during aircraft inspection and repair is operated at the Narita plant.

A hydraulic testing device capable of applying a load of up to 200 tons has been developed to support jack performance tests for medium-sized to large-sized machines.

Horiguchi Engineering: Partnership with German Hydro

Horiguchi Engineering Co., Ltd. signed a domestic distributorship contract for aviation equipment materials with Hydro (Germany: world’s leading: grand support equipment) in 2013.

Tests are conducted in-house using hydro-made jacks and maintenance know-how to ensure reliability.

In the past, it was necessary to send a jack after maintenance to Germany, which was costly and time-consuming.

Horiguchi Engineering: Contract with US Pratt & Whitney

Signed “License agreement on maintenance stand” for engines installed on airbus hit machine “A320” series etc.