TDK: MLCC: Industry’s first ‘CGAE’ series developed: Mass production for automotive in January 2020

January 28, 2020

TDK: Multilayer ceramic capacitor (MLCC)

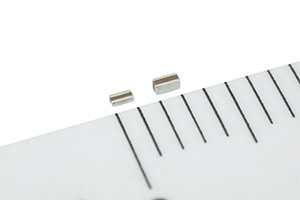

TDK has developed the “CGAE” series as a new series of multilayer ceramic capacitors (MLCC).

Announced that mass production began in January 2020 in the industry’s first vertically inverted horizontal / horizontal 0510 size for vehicles.

This product: “CGAE” series

Key features and benefits:

0510 / Small size, high capacitance (1μF)

Low ESL can contribute to the reduction of the number of staff

High reliability according to AEC-Q200

A structure in which the electrode direction is reversed 90 degrees vertically and horizontally compared to a normal type MLCC.

ESL (equivalent series inductance) and impedance are reduced by making the current route thick and short.

Conventional MLCC:

Already inverted MLCCs have been widely adopted for general use.

This MLCC:

For the first time, it has realized a large capacity of 0510 size (0.5 mm × 1.0 mm) / 1 μF, conforming to the automotive / AEC-Q200.

Fields of use:

ADAS: ADAS (Advanced Driver Assistance System) is increasingly important in terms of vehicle safety,

Automated driving: With the advancement of advanced functions with an eye to automatic driving,

Its control: need the same performance as PC or smartphone,

Noise countermeasures:

In particular, as ICs become more sophisticated, more and more decoupling MLCCs tend to be used as noise countermeasures.

Space saving of board:

In addition, as the demand for board space saving increases, more effective noise suppression products are required.

This product is effective for noise suppression and decoupling of automotive products.

https://www.jp.tdk.com/corp/ja/news_center/press/20200128_01.htm