Tamura Corporation: To mass production of solder for power semiconductors: Lead-free and heat resistant to 200 ° C

Tamura Corporation:

We have newly developed a lead-free solder joint material for power semiconductors.

Even if the temperature around the solder rises to 200 ° C, the bonding state does not deteriorate.

Silicon Carbide (SiC) and

Gallium Nitride (GaN),

Use gallium oxide for the substrate.

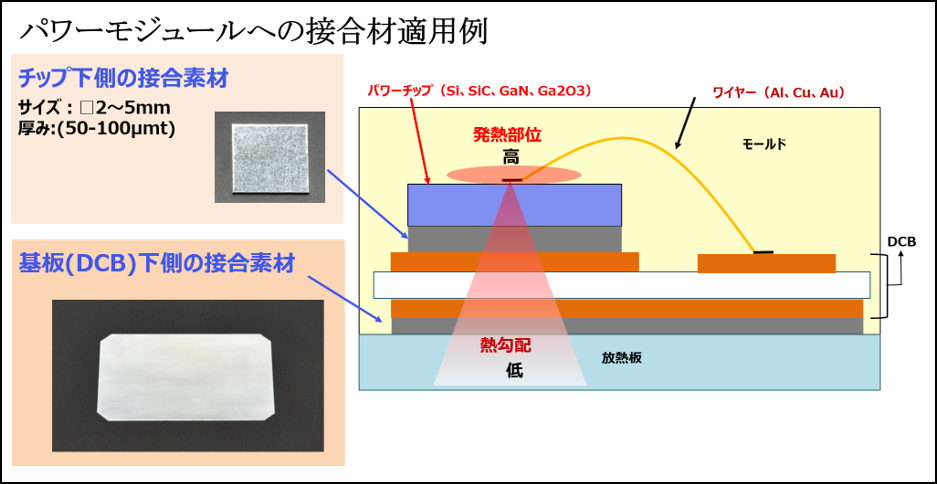

Expected to be used for “next-generation power semiconductors where the temperature of the connection part rises”.

We will start providing samples in March, aiming for mass production after 2023.

Demand for EVs and power sources is expected to grow.

Conventional power semiconductors have 150 degrees Celsius:

The element connection portion of a power semiconductor has a high temperature of about 150 degrees Celsius when used.

Next-generation power semiconductors are 200 degrees Celsius:

For next-generation power semiconductors using SiC, GaN, or gallium oxide

The temperature of the connection is said to rise to around 200 degrees Celsius.

For regular lead-free solder:

A small amount of silver and copper are added to tin.

A layer of compound is mounted on the plating of the connecting member.

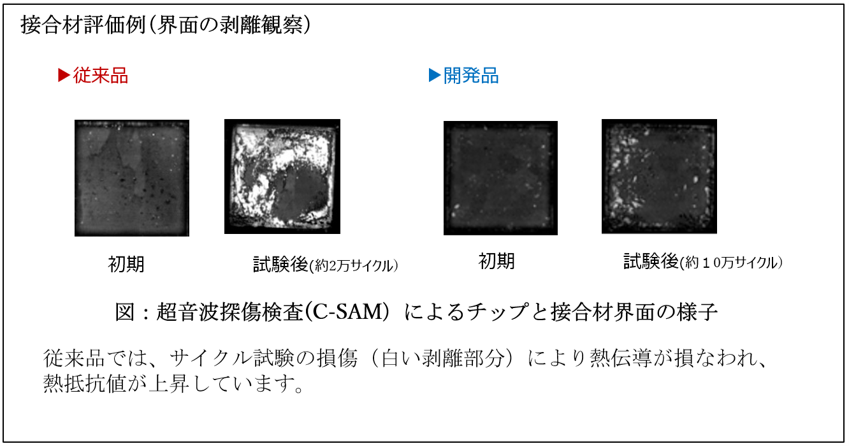

However, this layer causes cracks and causes deterioration of the joint.

In many cases, “normal lead-free solder does not have sufficient heat resistance.”

Features of the new lead-free solder:

A new lead-free solder composition developed by Tamura Corporation.

Antimony and copper were added to tin to ensure heat resistance.

It was

Tamura Corporation’s technology:

Due to the composition of this new product, no layers are formed and the joints are less likely to deteriorate.

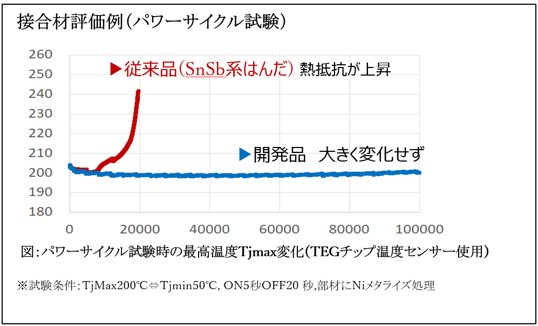

Reliability test results:

It maintained a high bonding rate even after the cycle life of twice that of the company’s solder products.

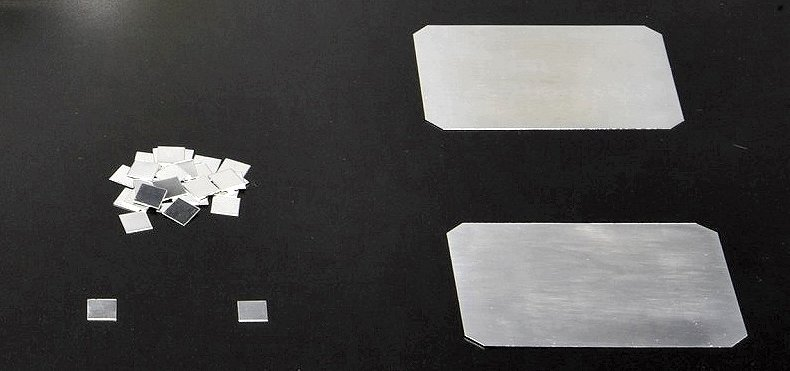

Sold as a sheet:

The product is sold in the form of a sheet that can be joined without pressure, which is often requested by the market.

Tamura Corporation subsidiary

Novell Crystal Technology

2021,

Next-generation power semiconductor material, gallium oxide,

For mass production of 100 mm wafers

It was the first success in the world.

Novell Crystal provides both materials and solder as a group.

New switch

Developed a 200 ° C high temperature, non-pressure bonded sheet with interface strengthening technology | Tamura Corporation