NEDO: Solar hydrogen production by artificial photosynthesis: Photocatalytic panel reaction system

August 26, 2021

NEDO:

Artificial Photosynthesis Chemical Process Technology Research Association (ARPChem):

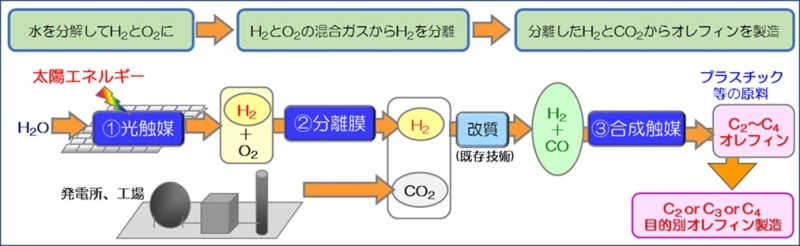

We have developed a photocatalytic panel reaction system for social implementation of artificial photosynthesis systems.

University of Tokyo,

FUJIFILM Corporation,

TOTO Ltd.,

Mitsubishi Chemical Co., Ltd.,

Shinshu University,

With Meiji University

For the first time in the world, we succeeded in a demonstration test.

Photocatalytic panel reaction system:

100㎡ solar light receiving photocatalyst panel reactor and

Connect the hydrogen / oxygen gas gas separation module,

We have developed a photocatalytic panel reaction system.

Separation and recovery of high-purity solar hydrogen:

Hydrogen produced by decomposing water and

Oxygen mixture gas From the mixture gas,

We have succeeded in separating and recovering high-purity solar hydrogen.

Safety design for solar hydrogen production:

In addition, the gas flow path has been properly designed.

Confirmed that the mixed gas can be handled safely for a long period of time.

Large-scale solar hydrogen production photocatalyst panel reaction system,

Contributes to the realization of safety design for solar hydrogen production.

Results of this research:

It was published in the online breaking news version of the British scientific journal “Nature” on Wednesday, August 25, 2021.

Photocatalytic panel reactor:

It was confirmed that “a mixed gas of hydrogen and oxygen is continuously generated for one year in an outdoor environment”.

Achieved “up to 0.76% solar energy conversion efficiency” when the summer sunshine conditions are good.

Aim for conversion efficiency of 5-10%:

The photocatalyst used this time absorbs only ultraviolet light.

Therefore, the solar energy conversion efficiency is as low as less than 1%.

Visible light and UV light absorption type photocatalyst:

Within the next few years, we will develop a photocatalyst that can absorb both visible and ultraviolet light.

We aim to achieve 5-10%.

NEDO

https://www.nedo.go.jp/news/press/AA5_101473.html

Photocatalytic solar hydrogen production from water on a 100 m2-scale

Abstract

The unprecedented impact of human activity on Earth’s climate and the ongoing increase in global energy demand

have made the development of carbon-neutral energy sources ever more important.

Hydrogen is an attractive and versatile energy carrier (and important and widely used chemical)

obtainable from water through photocatalysis using sunlight, and through electrolysis driven by solar or wind energy1,2.

The most efficient solar hydrogen production schemes, which couple solar cells to electrolysis systems,

reach solar-to-hydrogen (STH) energy conversion efficiencies of 30% at a laboratory scale3.

Photocatalytic water splitting reaches notably lower conversion efficiencies of only around 1%,

but the system design is much simpler and cheaper and more amenable to

scale-up1,2—provided the moist, stoichiometric hydrogen and oxygen product mixture can be handled safely in a field environment and the hydrogen recovered.

Extending our earlier demonstration of a 1 m2 panel reactor system based on a modified, aluminium-doped strontium titanate particulate photocatalyst4,

we here report safe operation of a 100 m2 array of panel reactors over several months with autonomous recovery of hydrogen from the moist gas product mixture using a commercial polyimide membrane5.

The system, optimized for safety and durability and remaining undamaged upon intentional ignition of recovered hydrogen, reaches a maximum STH of 0.76%.

While the hydrogen production is inefficient and energy negative overall,

our findings demonstrate that safe, large-scale photocatalytic water splitting and gas collection and separation are possible.

To make the technology economically viable and practically useful,

essential next steps are reactor and process optimization to substantially reduce costs and improve STH efficiency, photocatalyst stability and gas separation efficiency.

Nature