NEDO:通过人工光合作用生产太阳能:光催化面板反应系统

2021 年 8 月 26 日

尼多:

人工光合作用化学工艺技术研究协会(ARPChem):

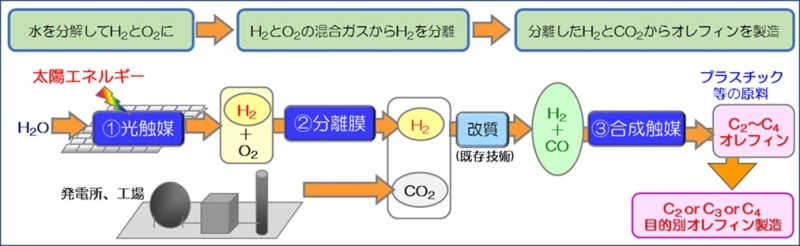

我们开发了一种光催化面板反应系统,用于人工光合作用系统的社会实施。

东京大学,

富士胶片公司,

多多有限公司,

三菱化学株式会社

信州大学、

与明治大学

我们在世界上第一次成功地进行了演示测试。

光催化面板反应系统:

100㎡太阳能受光光触媒板反应器及

连接氢气/氧气气体分离模块,

我们开发了光催化面板反应系统。

高纯太阳能氢气的分离回收:

水分解产生的氢气和

氧气混合气 从混合气中,

我们成功地分离和回收了高纯度的太阳能氢。

太阳能制氢安全设计:

此外,气体流路也经过适当设计。

确认混合气体可以长期安全处理。

大型太阳能制氢光触媒面板反应系统,

有助于实现太阳能制氢的安全设计。

这项研究的结果:

它于 2021 年 8 月 25 日星期三发表在英国科学期刊《自然》的在线破译版上。

光催化面板反应器:

已确认“在室外环境中连续一年产生氢气和氧气的混合气体”。

在夏季阳光条件好的情况下,实现了“高达0.76%的太阳能转换效率”。

目标转换效率为 5-10%:

这次使用的光触媒只吸收紫外线。

因此,太阳能转换效率低至不到1%。

可见光和紫外光吸收型光触媒:

在未来几年内,我们将开发出一种可以同时吸收可见光和紫外光的光催化剂。

我们的目标是达到 5-10%。

尼多

https://www.nedo.go.jp/news/press/AA5_101473.html

Photocatalytic solar hydrogen production from water on a 100 m2-scale

Abstract

The unprecedented impact of human activity on Earth’s climate and the ongoing increase in global energy demand

have made the development of carbon-neutral energy sources ever more important.

Hydrogen is an attractive and versatile energy carrier (and important and widely used chemical)

obtainable from water through photocatalysis using sunlight, and through electrolysis driven by solar or wind energy1,2.

The most efficient solar hydrogen production schemes, which couple solar cells to electrolysis systems,

reach solar-to-hydrogen (STH) energy conversion efficiencies of 30% at a laboratory scale3.

Photocatalytic water splitting reaches notably lower conversion efficiencies of only around 1%,

but the system design is much simpler and cheaper and more amenable to

scale-up1,2—provided the moist, stoichiometric hydrogen and oxygen product mixture can be handled safely in a field environment and the hydrogen recovered.

Extending our earlier demonstration of a 1 m2 panel reactor system based on a modified, aluminium-doped strontium titanate particulate photocatalyst4,

we here report safe operation of a 100 m2 array of panel reactors over several months with autonomous recovery of hydrogen from the moist gas product mixture using a commercial polyimide membrane5.

The system, optimized for safety and durability and remaining undamaged upon intentional ignition of recovered hydrogen, reaches a maximum STH of 0.76%.

While the hydrogen production is inefficient and energy negative overall,

our findings demonstrate that safe, large-scale photocatalytic water splitting and gas collection and separation are possible.

To make the technology economically viable and practically useful,

essential next steps are reactor and process optimization to substantially reduce costs and improve STH efficiency, photocatalyst stability and gas separation efficiency.

Nature