ITER: Succeeded in improving the level of tritium removal

・Introduced Japan’s latest tritium removal equipment

・Contributes to improving the safety of Fusion

We will provide you with a summary of articles published in QST.

National Institute for Quantum Science and Technology (QST):

ITER (International Thermonuclear Experimental Reactor) has upgraded its tritium removal equipment.

QST develops technology to remove tritium. Proposed to ITER.

Verification of tritium removal equipment:

It was confirmed that the tritium removal rate of ITER was met.

1. QST of Japan was in charge of the improvement work for the new equipment.

2. Additionally, performance verification tests were conducted at a facility in Japan.

Tritium safe handling technology:

This result will be useful not only for ITER but also for the development of Japan’s DEMO reactor.

This will greatly contribute to improving the level of technology for safely handling tritium.

What is ITER?

Seven regions (Japan, Europe, the United States, Russia, China, South Korea, and India) cooperate.

An experimental nuclear fusion reactor under construction in France.

National Institute for Quantum Science and Technology (QST):

QST will work with ITER to develop and verify the performance of tritium removal equipment.

The new equipment will further improve the safety of tritium removal equipment.

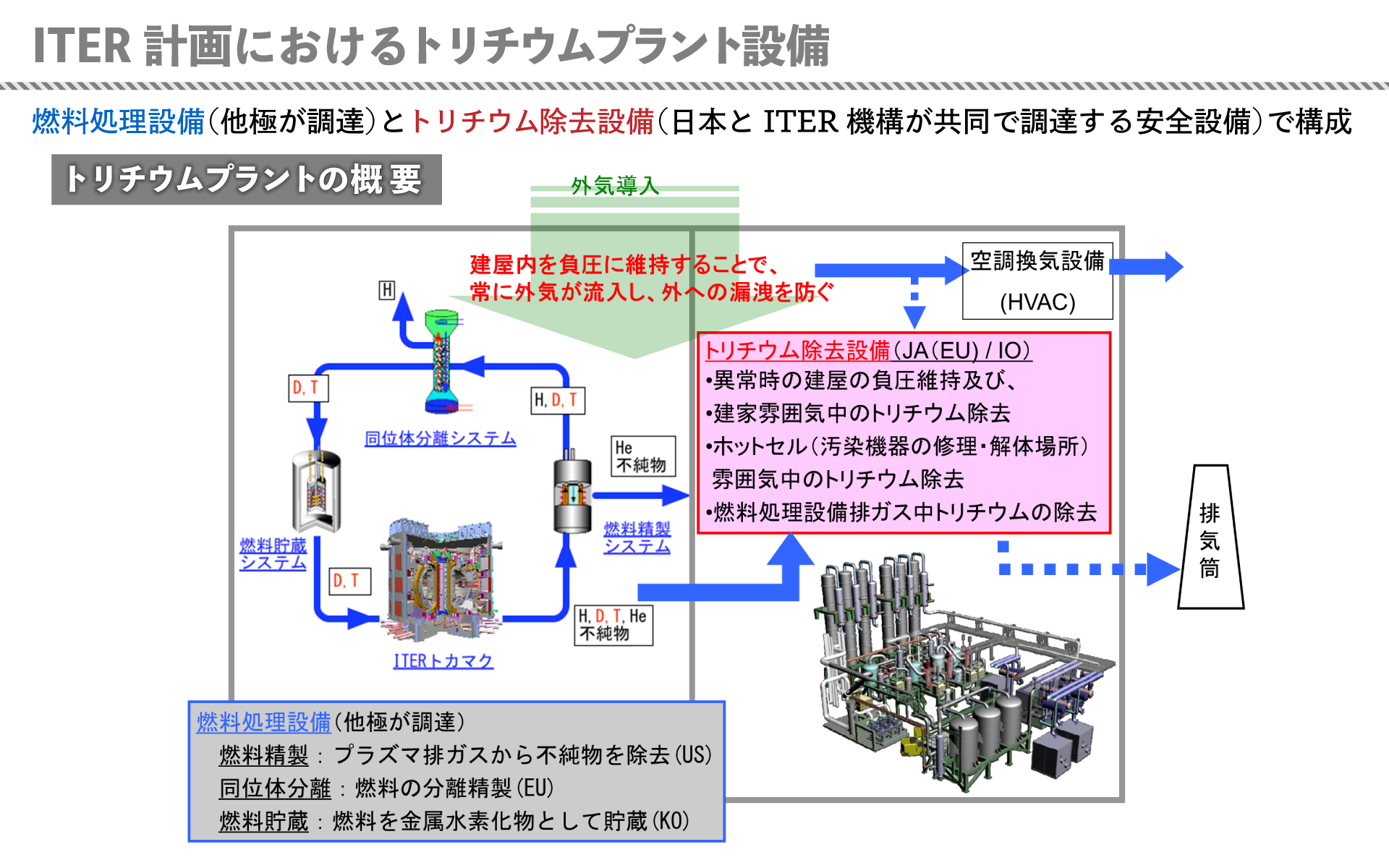

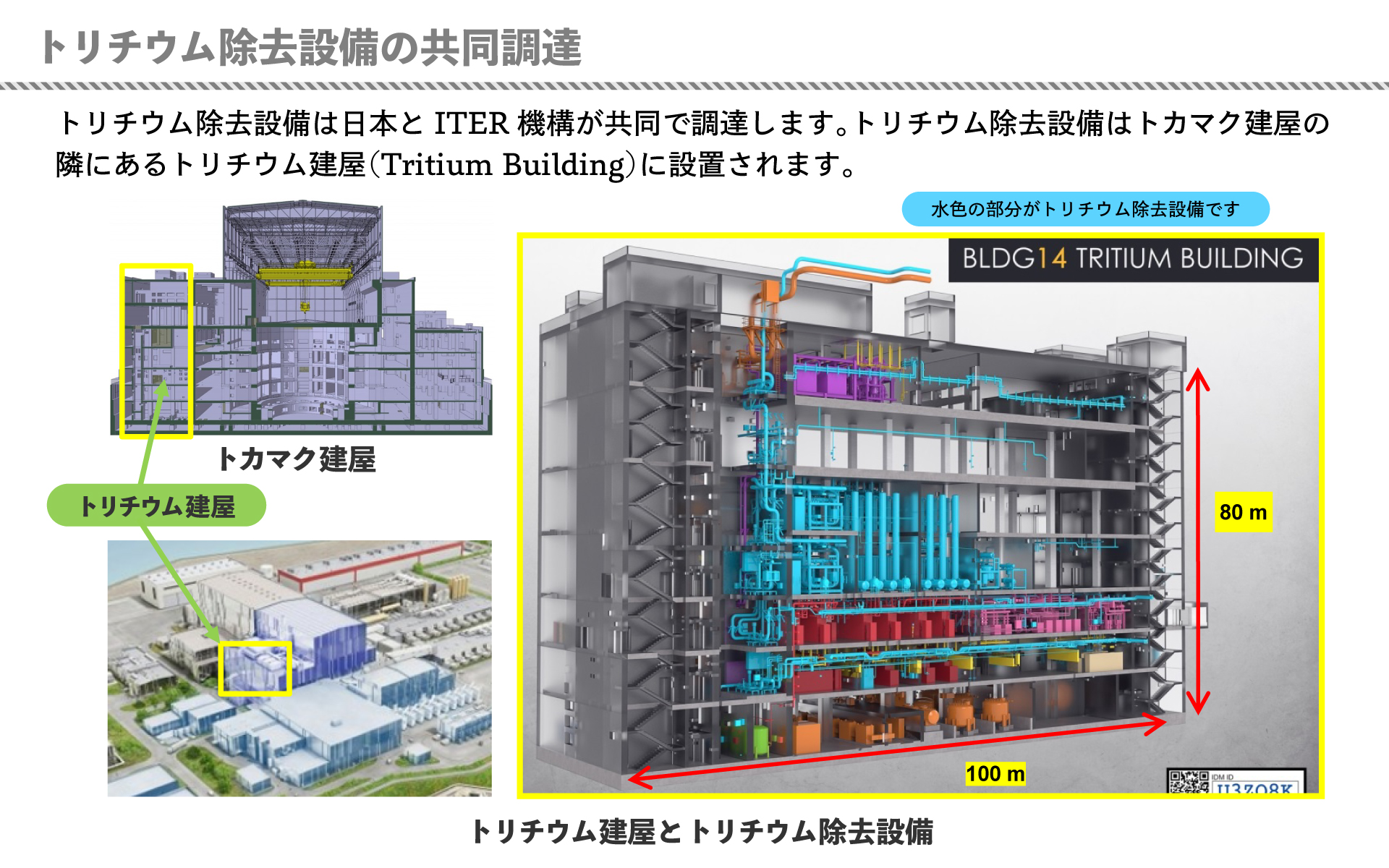

Relationship between ITER and tritium removal equipment:

In nuclear fusion, tritium is concentrated to high purity and used as fuel.

Tritium is radioactive:

1. It is important to remove tritium to prevent any impact on the public.

2. The tritium removal equipment removes tritium (=in the exhaust gas).

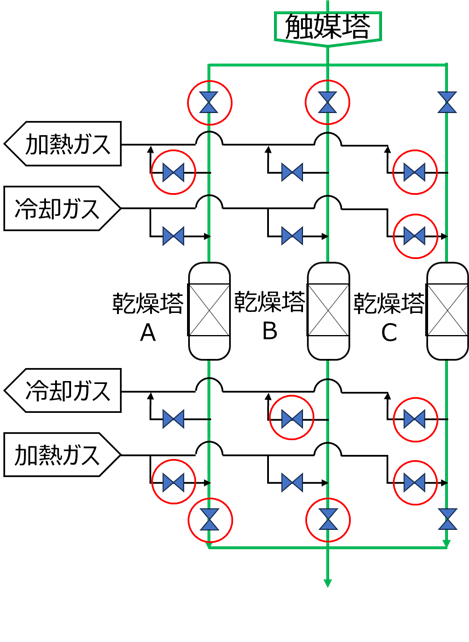

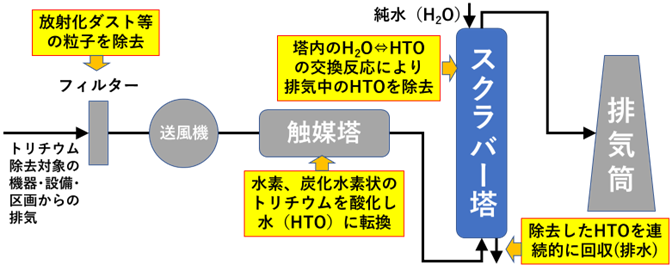

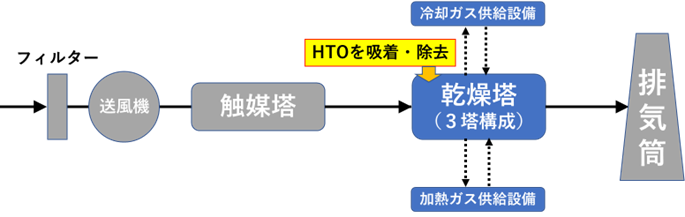

ITER uses a drying tower method:

ITER uses a method to adsorb and remove tritium using a drying tower.

The tritium in the exhaust gas is oxidized into water vapor.

Problems with the drying tower method:

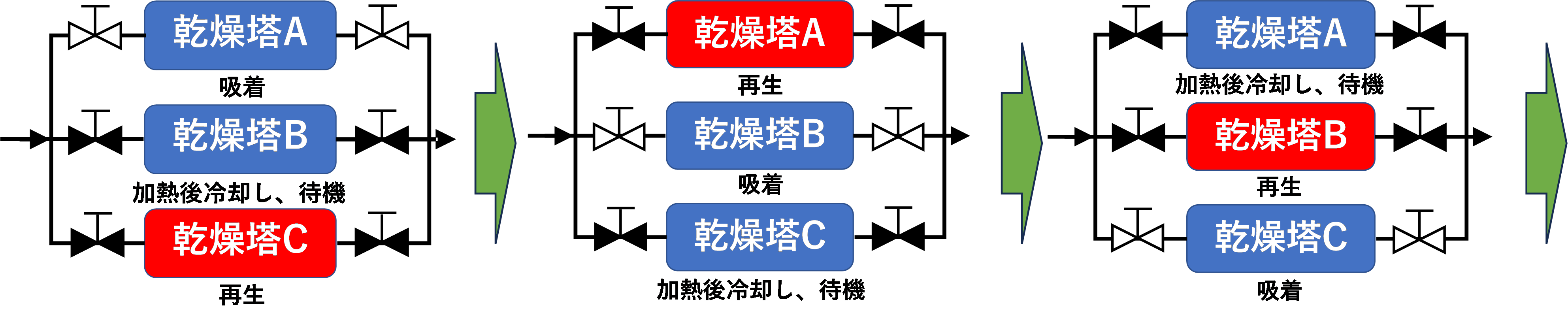

The drying tower consists of three towers: adsorption, regeneration, and standby.

1. Switch the status of the three towers in order and use the drying tower continuously.

2. Switching between these three towers requires frequent valve operations.

QST proposes scrubber tower method to ITER:

QST proposed a new system solution to ITER.

The conventional drying tower system will be changed to a scrubber tower system.

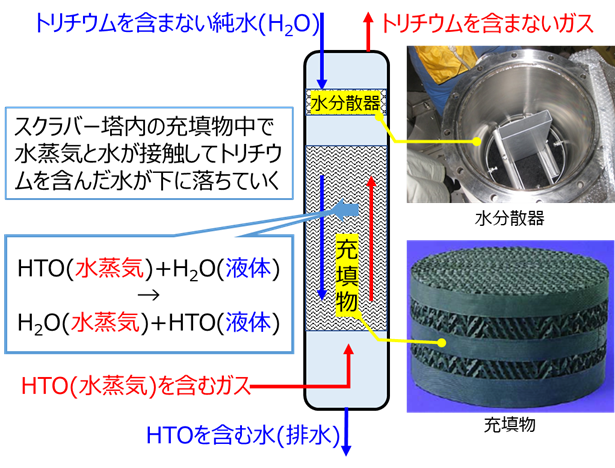

Tritium removal using scrubber column method:

The scrubber tower system continuously washes away water vapor containing tritium.

1. Pure water is introduced and sprayed into a tower filled with special packing.

2. All you need to do is introduce water into the tower.

Advantages of introducing scrubber tower method:

1. Reduces the risk of loss of functionality due to breakdowns due to complex equipment and operations

2. Improving equipment reliability will improve ITER safety

Continuous operation is possible by introducing the scrubber tower method:

ITER wants to prevent operational interruptions due to construction activities, etc.

‘Always operating the tritium removal function’ is an important issue.

Adopts Japanese scrubber tower method:

ITER adopted a Japanese tritium removal system.

1. The packing inside the column converts it into a substance that has an affinity for water.

2. The structure was modified to efficiently disperse the pure water inside the tower.

3. All you need to do is supply the same amount of pure water as the amount of steam in the tower.

Adoption of the scrubber tower method eliminated concerns about increased ITER wastewater volume.

Performance verification results of scrubber tower method:

The scrubber tower type tritium removal equipment has proven its long-term integrity.

1. Confirmed that the removal rate was met under various ITER conditions.

2. After 11 years of continuous operation, we confirmed that there was no performance decline due to aging.

This tritium removal technology:

1. Improve the safety of ITER and make great progress in the ITER plan.

2. Contributed to the ‘improvement of safe handling technology for tritium’ in Japan’s DEMO reactor.

Scheduled to be published in ITER Newsline (English).

ITER tritium removal equipment:

ITER’s tritium removal equipment will have the following safety functions:

1. Remove tritium from exhaust gas from equipment, equipment, areas, etc. that handle tritium.

2. Maintaining negative pressure to prevent the spread of radioactive contamination and remove tritium.

3. Filter aerosols and radioactive corrosive products. .

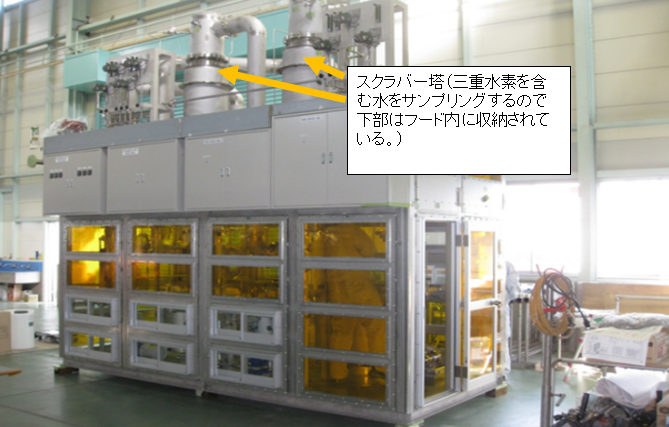

QST’s tritium removal equipment (scrubber tower type): Shown in Figure 2 (above).

Existing tritium removal equipment (using a drying tower): Shown in Figure 2 (below).

Compare Figure 2 (top) and Figure 2 (bottom):

The gray parts, filter → blower → catalyst tower, are the same.

The part that collects tritium was changed from a drying tower to a scrubber tower.

1. ITER safety is improved by adopting the scrubber tower method (Figure 2 (above diagram)).

2. Eliminates the need for “complicated drying towers and switching operations” that were previously required.

3. There is no risk of loss of function such as valve failure, and ITER reliability is improved.