BYD NIO’s power: I understood it by disassembling the Chinese NEV!

ーProfessor Masayoshi Yamamoto, Nagoya University [Interview]ー

-The latest trend of NEV in China-

Report from Response article

Online Seminar: “BEV trends revealed by disassembly”

On July 18th, “Trends of BEV seen disassembled” will be held.

Professor Masayoshi Yamamoto of the Institute of Materials and Systems for Sustainability, Nagoya University will be on stage at the seminar.

Professor Masayoshi Yamamoto:

The inverters of each company’s EV are disassembled and shared on SNS. The theme of the seminar is as follows.

1. Frontline of e-Axle for 2023 EV

2. Disassembled EVs in Japan, the US, Europe, and China (Hyundai/IONIQ5, Nissan/Aria, NIO/EC6, Tesla Model Y)

3. The forefront of in-wheel motors

4. 2030 EV market and its appearance

5. QA session

You can listen to Professor Yamamoto’s deep knowledge.

In an interview, we asked Prof. Yamamoto about the highlights of his seminar.

BYD e-axle downsizing:

It’s probably handled by Chinese BYD and downsized.

The engine room is also quite sparse. You can see the road through the gap.

Even the miniaturization of the inverter is thoroughly miniaturized.

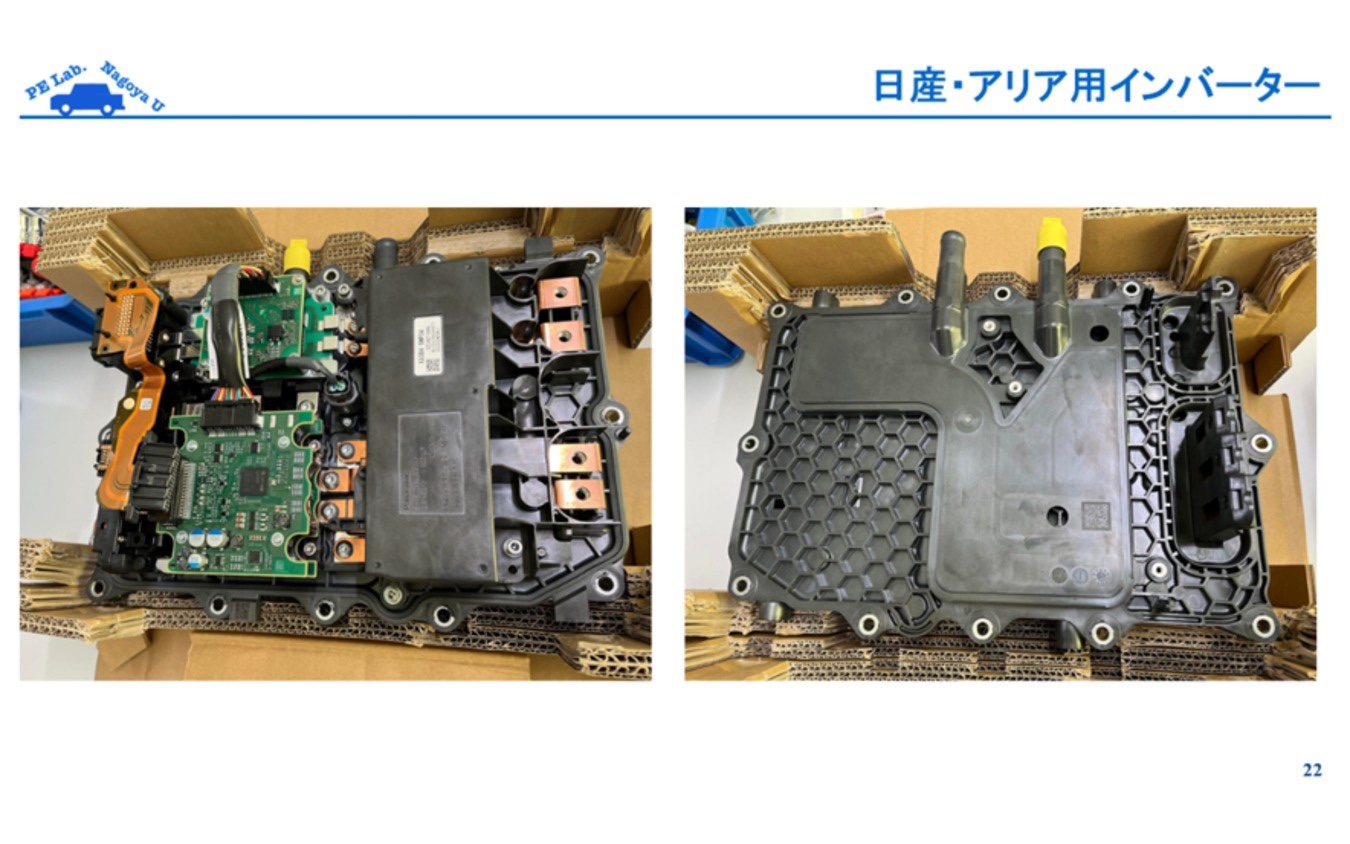

Nissan’s e-axle weight savings:

Then what we need next is weight reduction.

The e-axle inverter is very heavy. Nissan made the inverter resin.

The motor is heavier. The use of resin for motor cores is progressing.

This leads to a lighter in-wheel motor. The use of resin in components is typical of Japan.

NIO SUV EC6 teardown:

We disassembled “NIO’s top-selling middle-sized SUV EC6”.

I found out that “BYD ATTO3 is better than NIO SUV”.

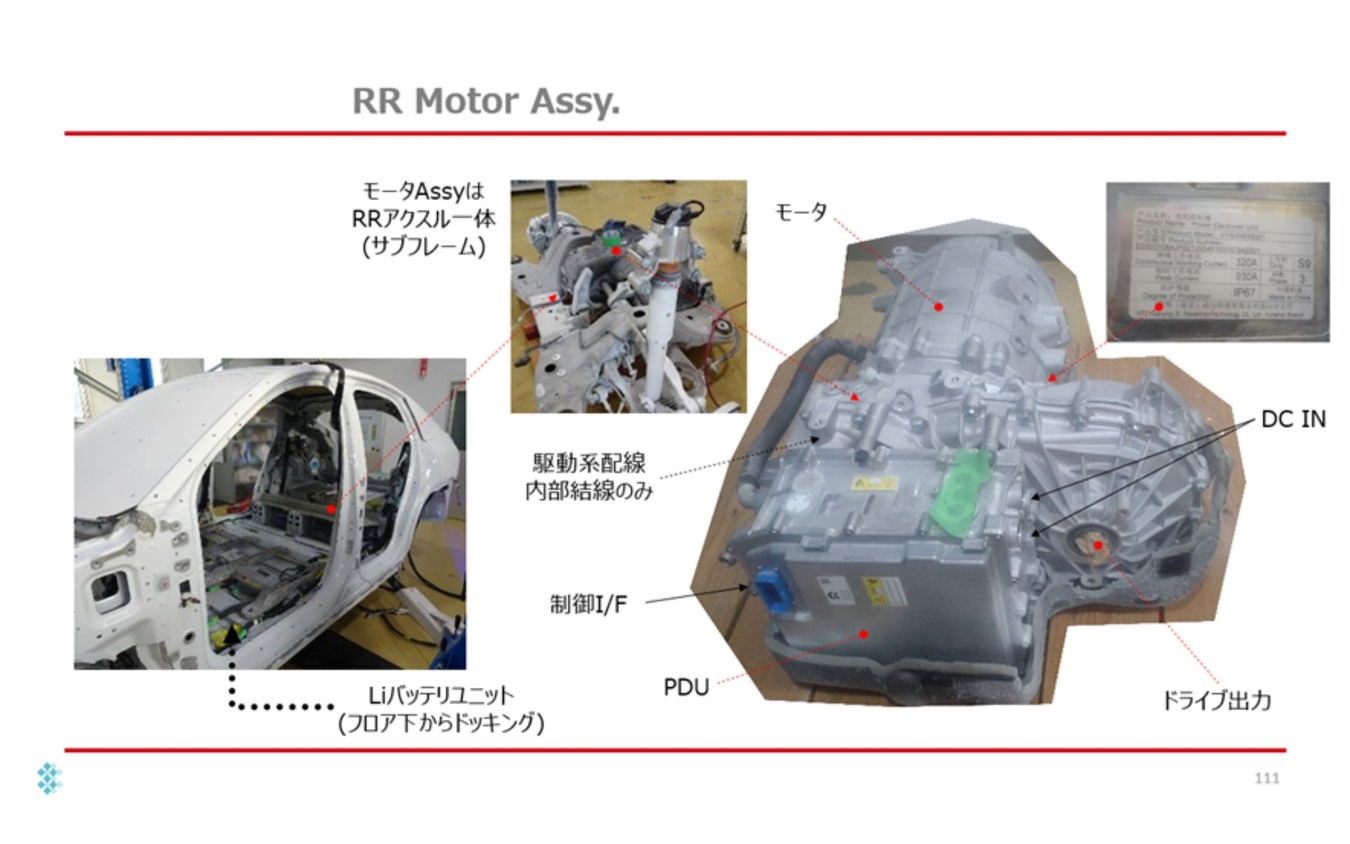

NIO mechanical part:

NIO uses a secondhand product in the drive unit. “The NIO line-up is all the same.”

The car body is also designed like a general-purpose product. Since we are fabless, we can only make such things.

Impressions after test driving NIO:

I took a test ride on a road with ups and downs in the Higashiyama district where Nagoya University is located.

Acceleration/deceleration or motor response is poor. I felt the rough handling.

Both the drive system and the frame are made in Europe, and the frame of the Jaguar i-Pace is diverted. simply assembled.

The company NIO is “in the battery business, not in the car itself.”

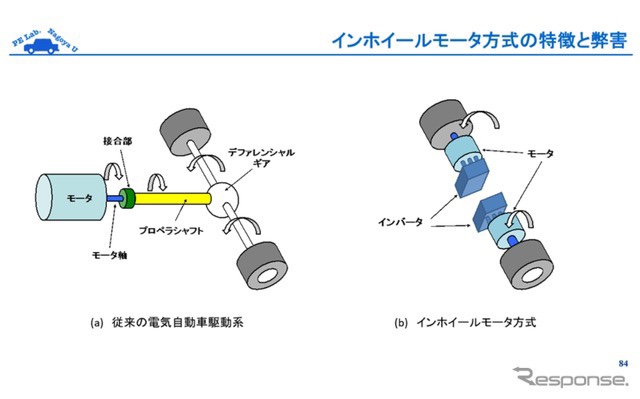

Notable in-wheel motors:

Professor Yamamoto raised in-wheel motors as a notable topic.

Dongfeng Motor will launch an in-wheel motor model this year.

In fact, Audi and Tesla were scheduled to go on sale in 2025. China did it two years earlier.

Combining in-wheel motors and 48V systems:

The problem with in-wheel motors is that the unsprung weight becomes very heavy.

An increase in unsprung weight by 1 kg increases the body weight by 10 to 20 kg. A 48V system solves this problem.

Audi’s SQ7 TDI:

2016 SQ7 TDI was equipped with “48V active stabilizer and active suspension”.

By combining with an in-hole motor, the disadvantages can be eliminated.

In-wheel motor: Less mechanical loss!

It is very important to be able to accelerate instantly.

Tesla: Model S Plaid

It is called a tri-motor, and one motor is placed on the left and right of the rear.

Audi: e-torn S Sportback

The Audi e-torn S follows the same pattern.

This is like the front stage of the in-wheel motor.

BYD’s EV bus: K9 high-end model

The “EV bus provided by BYD to Fujikyu Bus” is equipped with an in-wheel motor and is already running.

K9 high-end model. This technology is coming to passenger cars.