Tohoku Univ:GaN wafer inspection: luminous efficiency measure (omnidirectional photoluminescence )

[Summary of presentation]

- Establish high-speed, high-sensitivity inspection technology for large-scale GaN wafers for mass production

- Nondestructive and noncontact evaluation method of defect distribution based on absolute measurement * 2 of luminous efficiency * 1

- Applied to development and manufacture of semiconductor devices (power transistors, light emitting diodes, semiconductor lasers, solar cells)

【Overview】

Tohoku University Institute for Materials Science:

Hamamatsu Photonics:

We have developed a new semiconductor wafer inspection technology based on spectroscopy technology * 3.

Semiconductor devices are fabricated on crystalline substrates called wafers.

It is no exaggeration to say that the performance of a device depends on the quality of the crystals that make up the wafer.

Gallium Nitride (GaN):

It is attracting attention as one of the suitable materials for producing high-performance electronic devices and optical devices.

High-quality GaN wafers: Intensifying development competition

The widespread use of semiconductor devices requires mass production using large wafers.

In the case of GaN, circular wafers with a diameter of 6 inches (about 152 mm) or more are desired.

In order to control the quality of large GaN wafers, it is essential to have an evaluation method that can inspect the entire surface of the wafer with high speed and high sensitivity.

Associate Professor Kojima:

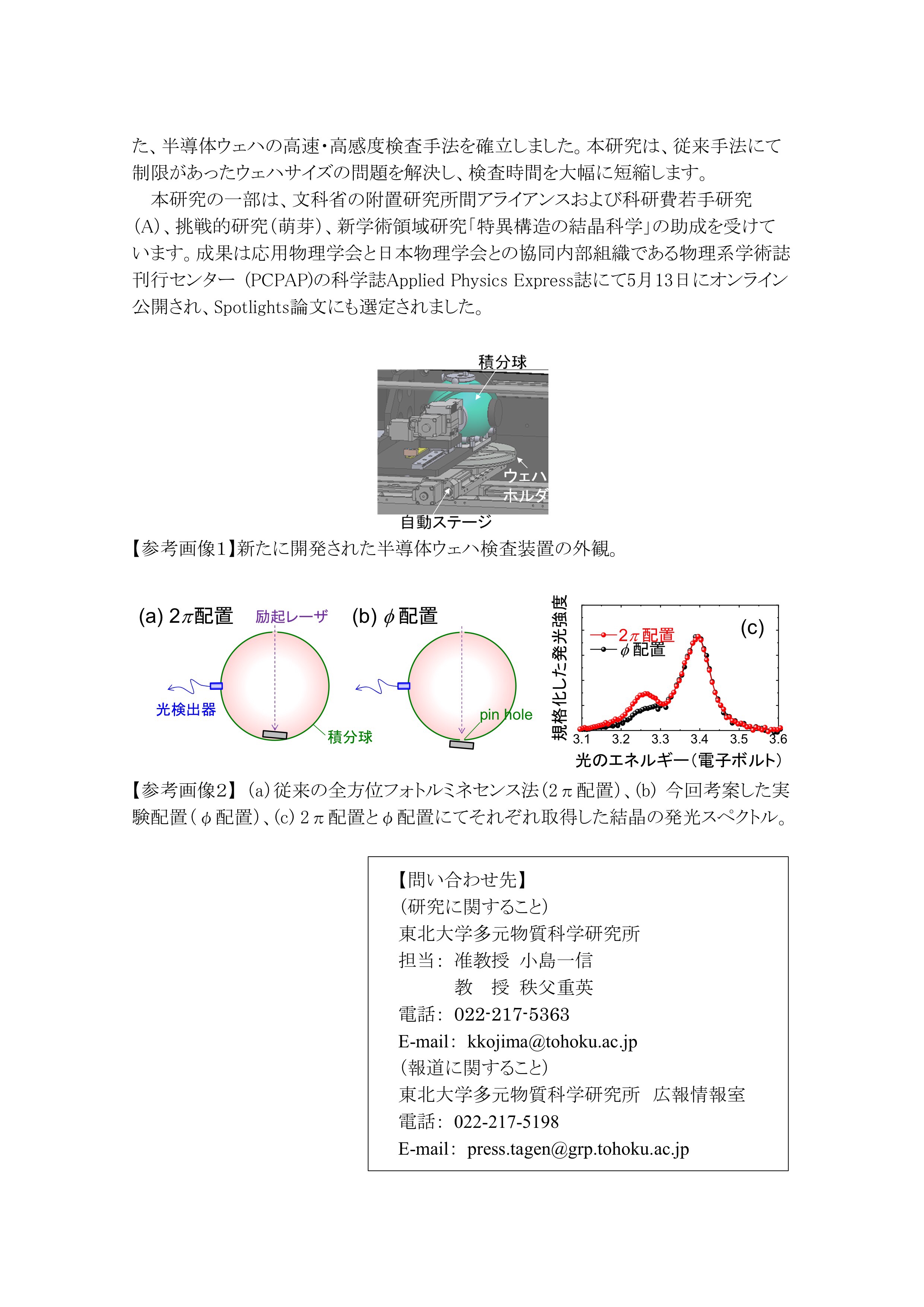

We apply high precision measurement method of luminous efficiency (omnidirectional photoluminescence method) of semiconductor crystal.

We have established a high-speed, high-sensitivity inspection method for semiconductor wafers by making full use of spectroscopy technology based on the integrating sphere * 5.

This research solves the problem of the wafer size which was limited by the conventional method, and the inspection time is greatly shortened.

Press Release | Tohoku University

https://www.tohoku.ac.jp/japanese/2019/05/press20190524-01-gal.html