Toray: PPS film、resistant to deformation even at the melting point: For circuit boards for 5G (FPC)

-Compatibility between dielectric properties and high thermal dimensional stability-

Toray: Development of new PPS film

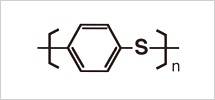

Toray has created a new PPS (polyphenylene sulfide) film.

It has excellent dielectric properties * 2, flame retardancy and chemical resistance.

Compared to conventional

Increase heat resistance over 40 ℃,

Hardly deforms even at temperatures close to the melting point

Has dimensional stability

Created a new PPS film.

5G board: Flexible printed circuit board (FPC) for high-speed transmission

The new PPS film is ideal for flexible printed circuit boards (FPC) * 3 for high-speed transmission.

In 5G, in addition to the frequency band below 6 GHz, it can be used in the high frequency band above 20 GHz.

Reduces transmission loss at high frequencies of communication devices,

Stabilizes high-speed communication in a wide range of environments such as high temperature and high humidity.

Disadvantages of LCP film: high cost, processability

For 5G / FPC component substrate materials,

- Dielectric properties to reduce transmission loss in high frequency band,

- Has properties such as heat resistance to solder when processing circuit boards

- Liquid crystal polymer (LCP) film is used.

However, LCP film had problems in high cost and processability.

Disadvantages of PPS film: deformation at high temperature, heat resistance

PPS film has excellent flame retardancy and chemical resistance.

In addition, it has excellent dielectric properties, especially resistance to temperature and humidity.

However, there was a problem that the film itself was deformed at high temperatures.

When processing circuit boards, solder heat resistance was insufficient.

This development: New PPS film

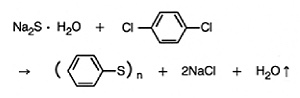

Toray has developed a proprietary technology for controlling the crystal structure of PPS films.

While maintaining the excellent properties of PPS polymer,The heat resistance was greatly improved.

New PPS film: Main features

New PPS film, “250 ° C heating test confirms that the film does not deform”

By increasing heat resistance, “you can use existing circuit board processing equipment”

Developed new technology, “Technology that can control orientation of molecular chains in film”

Thermal expansion coefficient: 98ppm / ℃

“Miniaturization design is possible by multi-layer circuit boards”

New PPS film: Introduction fields

By taking advantage of these features, it is expected to be used in a wide range of applications such as 5G transmission cables and antennas.

First, we will promote “Adoption in the FPC market centered on 5G smartphones”.

In addition, we will expand into a wide range of applications, such as “automotive applications and base station applications.”

Press Release | TORAY

https://www.toray.co.jp/news/chemicals/detail.html?key=4A196D8FC8D279BD492584D50006C97E