Daihen develops laser-arc hybrid welding:joins aluminum and steel

Daihen / Furukawa Electric

Daihen has developed a laser-arc hybrid welding system with Furukawa Electric to provide high quality and reliable joints.

Conventionally, fusion joining of dissimilar materials between aluminum alloy “aluminum” and galvanized steel sheet “steel sheet” has been difficult.

Sales will begin in January 2020 with Daihen as the point of contact.

Photonix 2019/2019 International Robot Exhibition

This product will be available at Photonix 2019 at Makuhari Messe (December 4 to 6, 2019, Furukawa Electric Booth No. 3-47) and at the Tokyo International Robot Exhibition 2019 Tokyo Robot Exhibition (December 18, 2019) We exhibited at Daihen booth No. Aomi B Hall B-18) from 21st to 21st.

Development background:

In order to reduce the weight of automobile bodies, high-strength steel sheets are applied to automotive parts to reduce the thickness.

“Welding technology for joining aluminum (leading lightweight material) and steel plate with high quality” was required.

Conventional technology:

In the joining of dissimilar materials between aluminum and steel sheets, fusion welding (arc welding / resistance spot welding) has been considered difficult due to differences in material properties such as melting point and thermal conductivity.

Fusion welding: disadvantages

In fusion welding, the heat input to the base metal increases, and brittle intermetallic compounds (hereinafter, IMC) are formed at the joints.

If the heat input is reduced to reduce IMC, it is not possible to form a bead width with sufficient bonding strength.

In other words, it has been said that it is virtually impossible to secure practical strength by joining dissimilar materials by welding.

This technology:

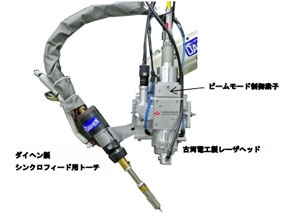

Daihen’s unique technology (current waveform control for aluminum welding)

Combining Furukawa Electric’s laser technology (precise heat input control possible)

We have commercialized our own welding and joining system.

Daihen: For aluminum welding, adopts current waveform control technology

An improved version of Daihen’s proprietary Synchro Feed Welding Method.

The required molten metal for the joint is supplied with extremely low heat input.

Furukawa Electric: Optical head with beam mode control function

An optical head with a beam mode control function from Furukawa Electric is used for the laser head.

When joining dissimilar materials by laser light, the joint is irradiated with the optimal shape and heat input.

As a result, the joining of dissimilar materials with high quality and reliability has become possible.

Laser-arc hybrid welding system: benefits

Based on conventional arc welding.

The current welding line equipment can be used.

There is no significant change in the shape of the structural members or the production process.

Half the processing time compared to dissimilar material joining methods using rivets or adhesives.

In addition, running costs can be reduced because 5000 series wire used for general aluminum welding is used as the welding material.

Daihen Corporation