Leaving China: To reduce the use of rare earths!

– Proterial, Denso, Toshiba, Toray

Technological development trends in Japan:

Japanese manufacturers are accelerating technological development to reduce the use of rare earths in motors.

Especially for EV motor magnets, they aim to replace magnets that use rare earth neodymium, which is currently the mainstream.

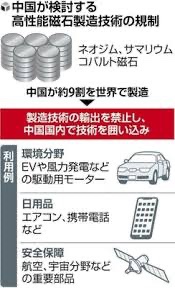

Share of rare earth mining:

China holds a 70% share of the world market. This threatens the economic security of each country.

Japanese companies will reduce their consumption as they break away from their dependence on China.

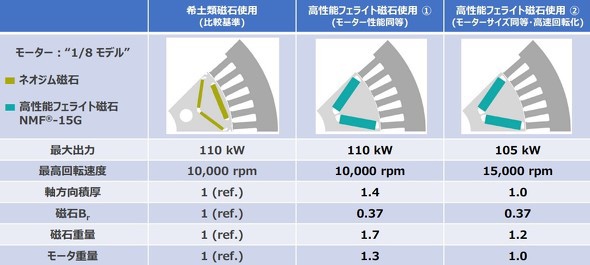

Proterial has developed a “high-performance ferrite magnet that can replace neodymium magnets” for EV motors.

We have already started supplying samples to motor manufacturers, and have received inquiries.

Ferrite magnets are mainly composed of iron and do not use scarce rare earths, so costs can be kept down.

By devising the manufacturing method and layout inside the motor, the maximum output of the motor approaching that of the neodymium magnet was secured.

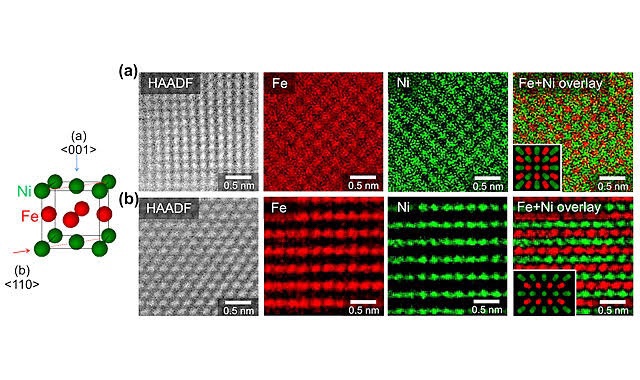

Fig. 3 STEM-EDX image of FeNi superlattice synthesized by NITE method

Denso’s “iron-nickel superlattice magnet”:

Denso’s new motor magnets use “only iron and nickel” and perform better than neodymium magnets.

Practical application of “iron-nickel superlattice magnet” in a few years.

Toshiba’s “samarium iron-based isotropic bonded magnet”:

Last year, Toshiba developed a new magnet with Tohoku University. Aiming for commercialization within a few years.

This magnet replaces neodymium with samarium, halving the amount used. Demonstrates the same performance as neodymium magnets.

Toray’s “highly durable zirconia balls”:

The movement to reduce the use of rare earths is also progressing in applications other than motors.

LIB electrode material production:

We have developed a “highly durable zirconia ball” that is used for crushing finely.

Replacing the rare earths used in stabilizers with other materials. Furthermore, we improved durability, reduced replacement, and reduced costs.

In the future, we will develop other applications such as bearings.

There are 17 rare earths in total:

Rare earths are used in various applications.

With China’s de facto embargo on Japan, recognition as an important commodity has increased.

The Chinese government is considering imposing an embargo on “high-performance magnets using rare earths.”

China’s intimidating attitude will further accelerate its move to reduce its use.

(Sankei Shimbun)-Yahoo! News

https://news.yahoo.co.jp/articles/fd3df0ba65641ce46dffd56776b66ab842bb6514