Japan: To collect cobalt and manganese in Minamitorishima

-Deep Earth exploration vessel “Chikyu” from the ocean floor-

-Secure hundreds of years’ worth of reserves-

We will deliver summaries of articles published in Sankei News.

Start of rare earth extraction in Japan:

Rare earths have been found on the ocean floor off the coast of Minamitorishima (Tokyo).

Adjustments have been made to start trial drilling from 2024.

This was revealed by multiple government officials on October 21st.

Japan’s rare earth imports:

Rare earths are essential for high-tech products.

Over 60% of the rare earths used in Japan are imported from China.

If the test drilling is successful, Japan will begin procuring rare earths on its own.

Hundreds of years worth of reserves:

Off the coast of Minamitorishima, large amounts of mud containing rare earth elements were found on the seabed at a depth of 6,000 meters.

According to research by the University of Tokyo, there are enough reserves to meet global demand for several hundred years.

Deep Earth exploration vessel “Chikyu”:

The plan is to extend a “sludge pump” from the deep-earth exploration vessel “Chikyu” to the ocean floor at a depth of 6,000 meters.

Recovering mud from the deep sea:

Last year, they successfully recovered mud from the seabed at a depth of 2,470 meters off the coast of Ibaraki Prefecture.

It sucks up 70 tons of mud per day.

Produced an underwater drone (ROV) for undersea work.

2 billion yen will be included in this year’s supplementary budget bill.

JAMSTEC Yokosuka Headquarters

The mud after the test drilling was analyzed by the Japan Agency for Marine-Earth Science and Technology (JAMSTEC).

In the future, a base facility for dewatering and separating mud will be established on Minamitorishima.

SStop China’s trade embargo:

Once upon a time, China began exporting rare earths to Japan in response to the ”Chinese fishing boat collision incident off the coast of the Senkaku Islands.”

This year again, China is expanding its rare earth regulations and economic coercion around the world.

https://www.sankei.com/article/20231021-5UZXTNA7UBLZFBRWNYSCU7DMJE/

University of Tokyo: Started development of Minamitorishima rare earth mud

We will provide you with a summary of articles published by the University of Tokyo Foundation.

China’s rare earth export regulations:

Currently, China accounts for most of the world’s rare earth production.

2010 “Rare Earth Shock” due to China’s rare earth embargo

In 2019, tensions escalated between the United States and China over rare earths.

Recently, China’s rare earth regulations have been further tightened.

University of Tokyo discovers rare earth mud:

In 2011, it was announced that deep sea mud could become a new rare earth resource.

The “rare earth mud” discovered

(1) Has high rare earth content

(especially heavy rare earths and scandium),

(2) It is widely distributed on the deep sea floor and has a huge amount of resources.

(3) It is easy to explore because it is distributed in layers;

(4) Clean resources that do not contain radioactive elements such as thorium and uranium;

(5) Rare earths can be extracted with dilute hydrochloric acid.

It can truly be called “dream mud.”

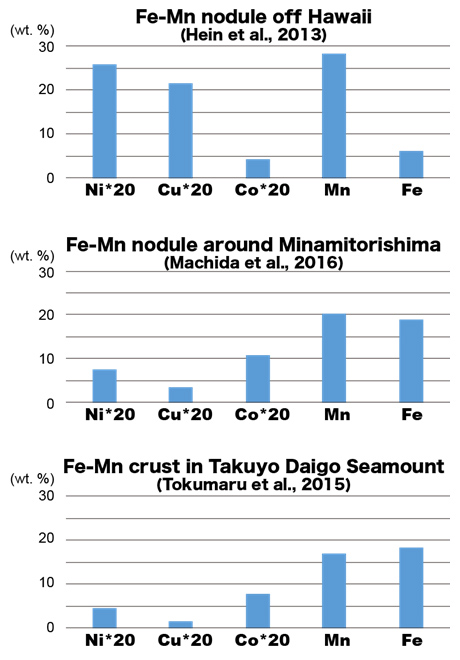

University of Tokyo analysis results

This rare earth mud from Minamitorishima is

The quality is 20 times higher than onshore mines in China.

This is the world’s highest grade ultra-high concentration rare earth mud.

A promising area of approximately 100 square kilometers alone would meet Japan’s annual demand for several hundred years.

Rare earth mud development system:

Floating Production, Storage and Offloading system: Application of FPSO.

“Airlift” technology

Air lift technology will be used to lift rare earth mud from the ocean floor.

Leaching of rare earths

Leaching rare earths from rare earth mud using dilute hydrochloric acid

Transports leaching solution and separates and purifies rare earths.

Sodium hydroxide is added to the residual mud to neutralize it and make it harmless, and it can be used as landfill material, cement material, or environmental material.

Cabinet Office’s “Innovative Deep Sea Resources Exploration Technology”

In 2018, development of rare earth mud extraction and pumping technology began.