Latest Tunnel Construction: Automated Operation with Robots

-Fully automated with Furukawa rock drills-

ーMaeda Corporation’s “shoring” robotー

We will deliver a summary from the NHK article.

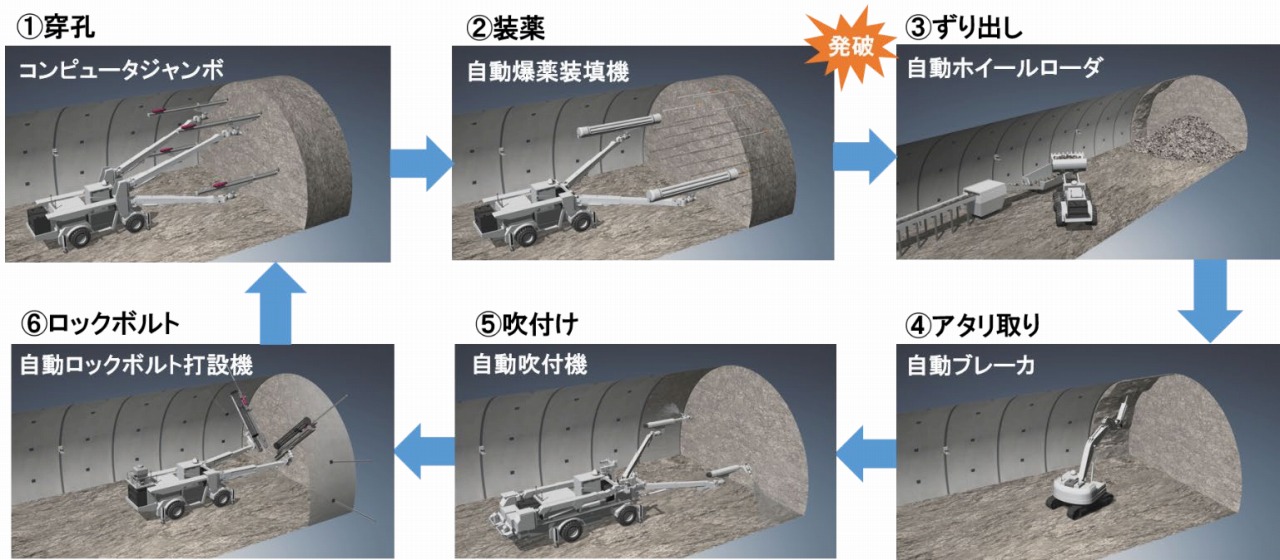

Automation of tunnel construction:

The construction industry has always had a shortage of workers.

Tunnel construction in particular is a difficult task in a closed space.

There are many burdens and dangers to workers. It is difficult for people to gather.

Solve this problem by developing automation technology!

“Furukawa Rock Drill”:

Automated skilled operations for tunnel construction in mountainous areas.

It automatically drills a hole in the rock and puts an explosive in the hole and blasts it.

A drill operator needs experience and intuition, and passing on the skills is a challenge.

Fully automatic drill system:

Enter the height and width of the tunnel to display the position of the hole required to charge the explosive.

Find the shortest route to drill all the holes.

The arm moves automatically and advances with the drill, so no operation is required.

Aiming for an unmanned environment in the tunnel site.

“shoring” robot:

Ensure worker safety by automating dangerous work in tunnels.

At Maeda Corporation, this robot is in charge of the iron frame installation work.

Robot specifications:

Automatically measure the shape of the tunnel. Adjust the arm in 1 cm increments. Install shoring.

Increase this robot adoption to increase safety.

The effects of introducing robots are enormous:

Work speed is improved and construction delays are greatly reduced.

We aim for safety and efficiency. The benefits to the construction industry are enormous.

https://www3.nhk.or.jp/news/contents/ohabiz/articles/2023_0515.html