Japan: semiconductor manufacturer, local production in Korea: Tosoh, ADEKA, Tokyo Electron

Thursday, May 28 11:31

Japan: Semiconductor manufacturer

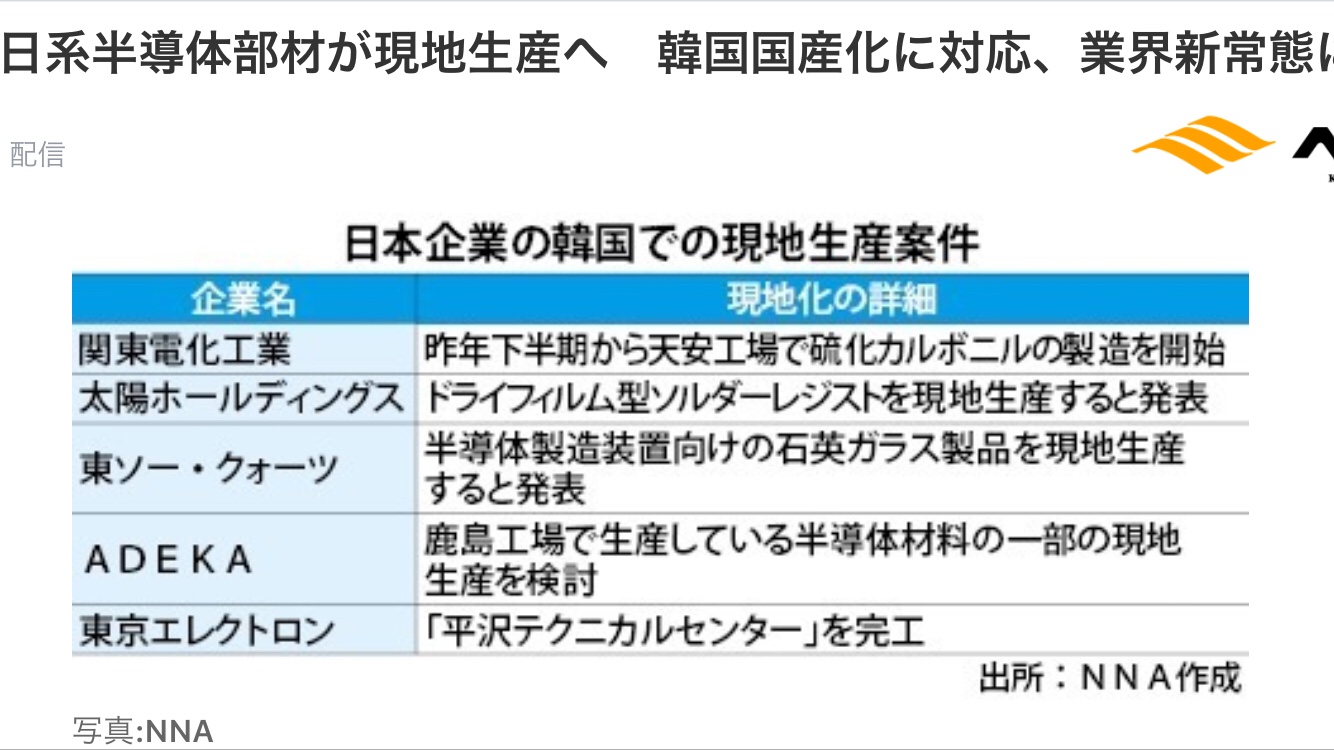

Japanese semiconductor component manufacturer is embarking on local production in Korea.

Last year, Kanto Denka Kogyo (Chiyoda-ku) started production at a Korean factory

Taiyo Holdings (Toshima Ward) has also announced the construction of a plant.

Government of Japan: Strict export control

The Japanese government announced in July last year that it will tighten export controls.

Since then, there is an increasing momentum to complete the domestic supply chain in Korea.

Taiyo Holdings: (PWB material manufacturer)

May 18, announced that it will produce a dry film type solder resist for semiconductor package substrates in South Korea.

Established new subsidiary “Taiyo Advanced Material” in June.

Established a new plant with a production capacity of 4 million square meters per year.

80% to 90% of the world share of dry film type solder resist,

Until now, produced at the Kitakyushu factory and exported to South Korea,

A spokeswoman for the company said, “From a business continuity plan (BCP) perspective, we also determined that local production was necessary.”

Dry film type/Solder resist:

Demand is expected to grow for IT equipment such as automobiles and smartphones, which are becoming increasingly electronic.

Semiconductors and smartphones/Samsung Electronics,

Development of self-driving cars / Hyundai cars,

Aim to secure future demand through local production in Korea.

Kanto Denka Kogyo

Started production of carbonyl sulfide in Cheonan, Chungcheongnam-do, South Korea.

A special gas used in the front-end process of semiconductors, which has not been produced in Korea so far.

Korean companies depended entirely on imports.

Established technical support center in Cheonan factory.

In terms of development, we plan to improve our ability to handle customers.

Tosoh:

Establish a local subsidiary to manufacture quartz glass for semiconductor devices by the end of the year.

Through the subsidiary / Tosoh Quartz, we are aiming for mass production in 2021.

ADEKA:

The Kashima Plant in Japan (Kamisu City, Ibaraki Prefecture) produces high dielectric materials “High-K materials”.

The policy is to “produce locally some semiconductor materials and expand supply for DRAM” (a spokeswoman for the company).

Tokyo Electron:

Established “Pyeongtaek Technical Center” near Samsung Electronics’ Pyeongtaek factory (Gyeonggi-do).

There are also moves to strengthen customer support.

Circumstances in Korea: (Person in the semiconductor industry)

The local industry “welcomes domestic production in Japan by Japanese companies,” he said.

Even if the Korean company succeeds in domestic production, “Korean products still have concerns that the yield rate will decrease.”

“The real intention is to continue using products made in Japan that guarantee high quality.”

Kanto Denka Kogyo: Public Relations Officer

“When the Cheonan factory started operations last year, our customer, a Korean company, welcomed us to local production,” he said.

The Korean government, which wants to reduce its dependence on Japan, seems to accept “domestic production” by Japanese companies.

(NNA)

https://news.yahoo.co.jp/articles/0fa2ac793a8b4b2d86ee1872066b7381fd6be1af