Japan QST: Developed hydrogen storage alloy Al13Fe4: Aluminum iron alloy

-the next generation technology for hydrogen storage materials-

Next-generation technology in Japan:

Multiple next-generation technologies have emerged for hydrogen storage alloys and storage materials.

The first one,

Al13Fe4 alloy:

The cost can be further reduced compared to titanium iron (Ti-Fe) based alloys.

It is Al13Fe4 consisting of Al and Fe.

The discovery of this alloy overturned the conventional wisdom and common sense of hydrogen storage alloy development.

There are still issues to be put into practical use, but there is a clear path to a solution.

The second is

MOF (Metal-Organic Framework):

There is also a disappointment with the Nobel Prize candidate.

A MOF (Metal-Organic Framework) -based hydrogen storage material will be put into practical use in a few years. It was

National Institutes for Quantum Radiological Science and Technology (QST)

Mr. Hiroyuki Saito

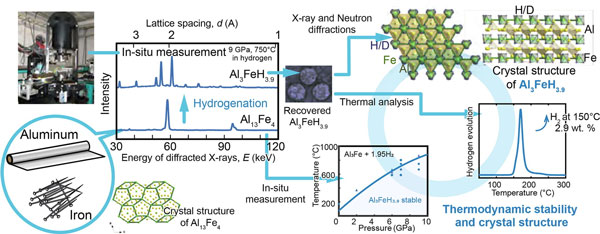

Developed a new hydrogen storage alloy “Al13Fe4” consisting of Al and Fe (Fig. 1)

The manufacturing cost of hydrogen storage alloys is cheaper than that of Ti-Fe series.

This hydrogen storage alloy:

Impact is not just cheap.

The discovery of this alloy overturns the conventional wisdom and common sense in the development of hydrogen storage alloys.

Characteristics of hydrogen storage alloy:

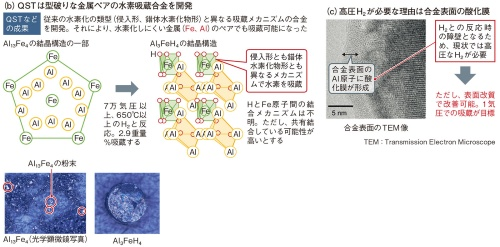

So far, there have been two “standards” in the development of hydrogen storage alloys.

The first one:

surely,

“Intrusive form” or “complex hydride form”

Choose from two types of material structures.

The second is:

Regardless of the type

One type each from “metals that are easy to hydrogenate” and “metals that are difficult to hydrogenate”

Choose a total of two types of metal.

Real face of Al13Fe4:

Al13Fe4 does not fit into either of the two formulas.

The H2 occlusion mechanism of Al13Fe4 is neither invasive nor complex hydride.

“The mechanism of occlusion has not been clarified” (Mr. Saito).

However, there is a high possibility that a covalent bond has occurred between the H atom and the Fe atom (Mr. Saito).

Problem solving:

Future issues are

“The solution is to occlude H2 only under ultra-high pressure and high temperature of 70,000 atm and 650 ° C or higher.”

Cause of the issue:

The cause of this is

This is due to the fact that an oxide film is formed on the Al atom on the surface of the alloy, preventing it from entering the inside of the H2 alloy.

However,

It turned out that “this problem can be improved by surface modification”.

Currently, we are conducting research and development with the goal of storing at 1 atm.

Nikkei Cross Tech (xTECH)

https://xtech.nikkei.com/atcl/nxt/column/18/01855/00012/

“Stores hydrogen with aluminum and iron without using rare elements”

-Leading new developments in hydrogen storage alloy development-

National Institutes for Quantum Radiological Science and Technology

Tohoku University

High Energy Accelerator Research Organization

J-PARC Center[Summary of presentation]

Without containing rare metals as in the past

With a resource-rich alloy of aluminum and iron

I discovered that hydrogen can be stored.

Discovered based on the new idea of ”combining metals that do not easily react with hydrogen”The range of material search for hydrogen storage alloys in the future will be dramatically expanded.

Expected to realize practical materials that do not contain rare metals

National Institutes for Quantum and Radiological Science and Technology (QST)

http://www.tohoku.ac.jp/japanese/newimg/pressimg/tohokuuniv_press20210728_01web_element.pdf

Hydrogen storage by earth-abundant metals, synthesis and characterization of Al₃FeH₃.₉|

– IMR – Institute for Materials Research, TOHOKU UNIVERSITY

http://www.imr.tohoku.ac.jp/en/news/results/detail—id-1351.html