Iwatani : Successful production of DHA and hydrogen from waste glycerol: DHA production cost reduction

Succeeded in developing a catalyst that converts glycerin into DHA under normal temperature and pressure

~DHA manufacturing cost can be reduced~

Iwatani Sangyo:

In collaboration with Osaka University, we succeeded in “development of inorganic catalyst using rare earth”.

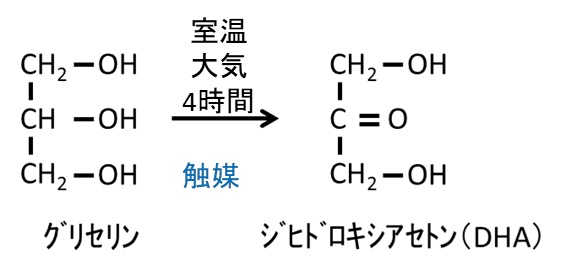

“Converts glycerin to dihydroxyacetone (DHA) at room temperature and atmospheric pressure in a short time“, “inorganic catalyst using rare earths“.

Inorganic catalysts that convert to DHA:

We applied for a patent jointly.

Synthesis of DHA from glycerin in a short time under mild conditions

Significant reduction in DHA manufacturing time and cost

Biodiesel Manufacturing: The Problems

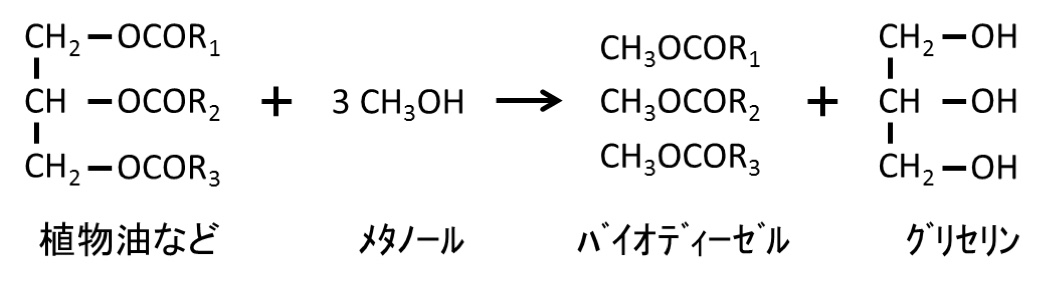

In recent years, biodiesel has attracted attention as an alternative energy to fossil fuels.

However, glycerin is produced as a by-product during biodiesel production, which results in an oversupply of glycerin.

Effective use of waste glycerin:

Most of them are currently discarded because they have no effective use.

Effective utilization of glycerin and high added value are required.

Technology possessed by Osaka University:

The conversion of glycerin to DHA usually requires a special environment such as a microbial fermentation process or reaction at high temperature and pressure.

On the other hand, the use of “inorganic catalysts using rare earths” enabled high DHA production and reduction of DHA production cost under mild conditions.

Effective use of DHA:

“DHA obtained by oxidation of the 2-hydroxy group of glycerin” is

Cosmetics such as sunless tanning*4,

As an intermediate raw material for medical and agricultural chemicals

You can expect demand.

Iwatani Corporation:

Iwatani Sangyo handles a wide range of rare metal raw materials such as the rare earths used in this catalyst.

As we proceeded with the application development of these raw materials, we focused on the technology of Osaka University.

In the future, we will propose to catalyst manufacturers and DHA manufacturers for commercial production.

We recruit partner companies and work toward commercialization.

http://www.iwatani.co.jp/img/jpn/pdf/newsrelease/1349/20200526_news_jp1.pdf

Tokyo Tech: Successful production of DHA and hydrogen from waste glycerol

Uses inexpensive copper oxide, which is abundant on the earth, as a catalyst

Results of this research:

CuO, which is abundant and inexpensive on the earth, is used as a catalyst.

This is the establishment of a technology for selectively producing DHA and hydrogen, which are used in cosmetics, sweeteners, etc., from glycerin, which is a waste during biodiesel production.

Especially, the chemical reaction on the surface of CuO catalyst was observed in situ using Raman spectroscopy.

Elucidation of reaction mechanism,

To maximize reaction selectivity

Two of the optimization of reaction conditions were achieved.

Tokyo Tech News | Tokyo Institute of Technology