Gigaphoton: Mass production of ArFi light source GT66A: EUV miniaturization

-New technology to accelerate the technology shift-

December 16, 2020

Gigaphoton:

December 16, 2020, Gigaphoton, a light source manufacturer for semiconductor lithography (Headquarters: Oyama City, Tochigi Prefecture, President: Katsumi Uranaka)

Latest semiconductor manufacturing ArF immersion lithography light source “GT66A” using new technology

Announced that mass production shipments have started.

State-of-the-art device manufacturing:

Currently in logic devices

3nm node process development started,

Mass production of 1Znm node has started for DRAM.

For ultra-fine devices, reducing the roughness of the exposure pattern transferred to the wafer is an issue.

“Reproducing the circuit pattern faithfully and improving the yield in mass production” is the most important issue.

New ArF immersion light source “GT66A”:

Newly developed optical module.

Succeeded in “extending the pulse emission time more than 3 times as much as before”

Achieves improved beam uniformity on the exposed surface.

We have succeeded in reducing roughness.

Certified as ASML light source:

In addition, the latest durable components can extend the module maintenance cycle by 30%.

GT66A has been certified as a light source for the latest ArF immersion exposure system NXT: 2050i by ASML, a major Dutch company.

Mass production shipment of light sources for end users will begin.

Welcome to Gigaphoton

https://www.gigaphoton.com/ja/news/6618

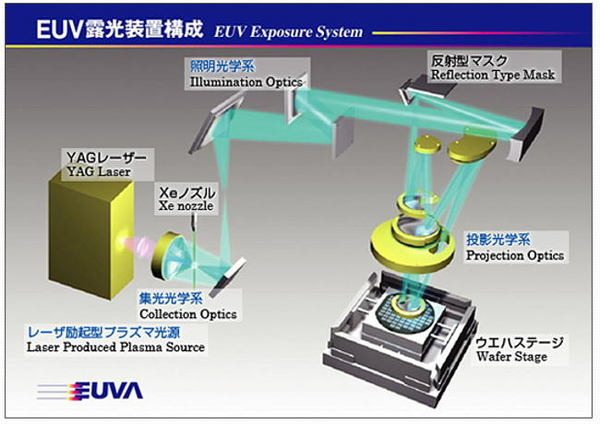

Basic configuration of EUV exposure equipment: Explained in the figure

The figure shows the basic configuration of the EUV exposure apparatus.

For EUV functional modules:

Laser excitation type plasma light source (hereinafter referred to as light source),

Illumination optics,

Reflective mask,

Projection optics,

There is a wafer stage.Light source manufactured by US Cymer:

Currently, ASML’s subsidiary Cymer manufactures light sources.

US Government Export Review:

As a result of the US government’s pressure on the Dutch government, ASML was unable to ship EUV to SMIC.

One of the reasons is that “American-registered company Cymer is making a light source, which is a very important module of EUV.”

ASML will not be able to export “EUVs that use Cymer-manufactured light sources” to SMIC in the future.

Light source for Gigaphoton manufacturing in Japan:

However, there is another company that can make EUV light sources.

It is a Japanese gigaphoton.

Currently, the EUV that TSMC and Samsung are applying for mass production of 7 to 5 nm is equipped with a Cymer light source instead of Gigaphoton.

Origin of “prepulse” technology:

It is also conceivable to replace ASML’s EUV light source with “Cymer to Gigaphoton”.

This is because “the technology called” prepulse “that Cymer uses for EUV light sources” was originally “developed by Gigaphoton.”

“Prepulse” is a technology that irradiates tin droplets with a laser in two stages.

Replacing EUV light sources from US cymers to Japanese gigaphotons will allow ASML to export EUV to SMIC.

JBpress (Japan Business Press)

https://jbpress.ismedia.jp/articles/-/63474

NEDO: EUV pilot light source demonstrates world’s highest level of luminous efficiency of 5%

-In the NEDO project-

Gigaphoton Co., Ltd .:

We have completed a laser-generated plasma light source for EUV scanners that is intended for operation on cutting-edge semiconductor manufacturing lines.

We have demonstrated stable operation with an output of 105W and a luminous efficiency of 5%, which is the highest level in the world.

The success of this operation demonstration has brought us very close to the realization of a state-of-the-art semiconductor manufacturing line.

NEDO

https://www.nedo.go.jp/news/press/AA5_100659.html

Gigaphoton Begins Mass Production and Shipment of the ARFi GT66A Light Source Compatible with Cutting-Edge Miniaturization Technologies

December 16, 2020

Equipped with New Technologies to Accelerate a Technological Shift

Oyama, Tochigi; December 16, 2020, GIGAPHOTON Inc. (Head office: Oyama, Tochigi; President & CEO: Katsumi Uranaka), a manufacturer of light sources for semiconductor lithography,

has announced the start of mass production and shipment of the ArF immersion “GT66A” light source using new technologies for state-of-the-art semiconductor lithography manufacturing.

GT66A is now certified as a light source for the latest ARF immersion lithography equipment NXT:2050i by ASML, the leading Dutch company,

and mass production and shipment of the light source to end-users will now commence.

Leading-edge device manufacturing

has now begun with the process development of 3 nm nodes for logic devices and mass production of 1 Znm DRAM.

the yield in mass production

For these ultra-fine devices, reducing the roughness of the exposure patterns transferred to wafers is a challenge.

It is important to reproduce the circuit pattern precisely and increase the yield in mass production.

The new ArF immersion “GT66A” light source

is equipped with a newly developed optical module that successfully improves the beam uniformity on the exposed surface and reduces the roughness by increasing the temporal coherence length by at least 3 times that of the existing model.

The maintenance cycle of the module

has been extended by 30% with the introduction of the latest components with high durability.

Katsumi Uranaka, President and CEO of GIGAPHOTON, said:

“In recent years, semiconductor chips are required to support even faster communication speeds and process larger amounts of data.

This is mainly supported by the miniaturization of logic and memory semiconductors and requires higher productivity through further innovation of lithography technology.

GIGAPHOTON

will continue its contribution to the development of the next generation of industries by improving the imaging performance through technological innovation and increasing the availability of light sources.”

Welcome to Gigaphoton