ASML/Nikon withdraws: China’s SMIC is not in trouble!

ーIn the future, only Japan will suffer big lossesー

hong kong media

“Asia Times”

Even if ASML and Nikon withdraw from the Chinese market,

“China’s largest semiconductor manufacturer Core International Integrated Circuit Manufacturing (SMIC)” is no problem.

SMIC:

Already from the summer of 2022, it has been manufacturing semiconductors using 7nm process technology.

this is,

7nm process semiconductors cannot be made without ASML and Nikon’s semiconductor manufacturing equipment.

“SMIC purchased a lot of equipment from ASML and Nikon.”

“Semi-analysis”

Dylan Patel

“The size of SMIC’s production capacity” is something to behold.

SMIC is already using only existing equipment, using the 7nm process,

It is possible to “produce 100,000 semiconductors per month.”

SMIC’s production capacity:

This is “more than the combined production capacity of Samsung and Intel.”

Patel commented:

If SMIC uses all semiconductor manufacturing equipment owned by Chinese companies,

SMIC’s 7 nm process semiconductor manufacturing capacity far exceeds Taiwan’s TSMC.

In addition, regarding mass production, the development of semiconductor manufacturing equipment is progressing within China.

Shanghai Micro Electronic Equipment Co., Ltd. (SMEE):

“We have developed a lithography system that can handle up to 14 nanometers,” he said.

The technology of Chinese manufacturers will also improve in the future.

– Yahoo! News

https://news.yahoo.co.jp/articles/214f1f0709bf201ec2bff1b5e3916af9810d9376

ASML/Nikon se retire : le SMIC chinois n’est pas en difficulté !

ーÀ l’avenir, seul le Japon subira de grosses pertesー

médias de hong kong

“L’heure de l’Asie”

Même si ASML et Nikon se retirent du marché chinois,

“Le plus grand fabricant chinois de semi-conducteurs Core Core International Integrated Circuit Manufacturing (SMIC)” n’est pas un problème.

SMIC :

Dès l’été 2022, elle fabrique des semi-conducteurs en utilisant la technologie de procédé 7 nm.

c’est,

Les semi-conducteurs de processus 7 nm ne peuvent pas être fabriqués sans l’ASML et l’équipement de fabrication de semi-conducteurs de Nikon.

“SMIC a acheté beaucoup d’équipements auprès d’ASML et de Nikon.”

“Semi-analyse”

Dylan Patel

“La taille de la capacité de production du SMIC” est quelque chose à voir.

SMIC n’utilise déjà que des équipements existants, utilisant le procédé 7nm,

Il est possible de “produire 100 000 semi-conducteurs par mois”.

Capacité de production du SMIC :

C’est “plus que la capacité de production combinée de Samsung et d’Intel”.

Patel a commenté :

Si le SMIC utilise tous les équipements de fabrication de semi-conducteurs appartenant à des entreprises chinoises,

La capacité de fabrication de semi-conducteurs de procédé 7 nm de SMIC dépasse de loin celle de TSMC de Taiwan.

De plus, concernant la production de masse, le développement d’équipements de fabrication de semi-conducteurs progresse en Chine.

Shanghai Micro Electronic Equipment Co., Ltd. (SMEE) :

“Nous avons développé un système de lithographie qui peut gérer jusqu’à 14 nanomètres”, a-t-il déclaré.

La technologie des fabricants chinois s’améliorera également à l’avenir.

– Actualités Yahoo!

ASML/Nikon zieht sich zurück: Chinas SMIC ist nicht in Schwierigkeiten!

ーIn Zukunft wird nur Japan große Verluste erleidenー

Hongkonger Medien

“Asienzeit”

Auch wenn sich ASML und Nikon vom chinesischen Markt zurückziehen,

“Chinas größter Halbleiterhersteller Core Core International Integrated Circuit Manufacturing (SMIC)” ist kein Problem.

SMIC:

Bereits seit Sommer 2022 fertigt es Halbleiter in 7-nm-Prozesstechnologie.

das ist,

7-nm-Prozesshalbleiter können nicht ohne ASML und Nikons Halbleiterfertigungsanlagen hergestellt werden.

“SMIC kaufte viele Geräte von ASML und Nikon.”

“Halbanalyse”

Dylan Patel

„Die Größe der Produktionskapazität von SMIC“ kann sich sehen lassen.

SMIC verwendet bereits nur vorhandene Geräte im 7-nm-Prozess,

Es sei möglich, “100.000 Halbleiter pro Monat zu produzieren”.

Produktionskapazität von SMIC:

Das sei „mehr als die gemeinsame Produktionskapazität von Samsung und Intel“.

Pattel kommentierte:

Wenn SMIC alle Halbleiterherstellungsanlagen verwendet, die chinesischen Unternehmen gehören,

Die Fertigungskapazität von SMIC im 7-nm-Prozess für Halbleiter übertrifft die von Taiwans TSMC bei weitem.

Darüber hinaus schreitet die Entwicklung von Halbleiterfertigungsanlagen in China in Bezug auf die Massenproduktion voran.

Shanghai Micro Electronic Equipment Co., Ltd. (SMEE):

“Wir haben ein Lithografiesystem entwickelt, das bis zu 14 Nanometer verarbeiten kann”, sagte er.

Auch die Technik der chinesischen Hersteller wird sich in Zukunft verbessern.

– Yahoo Nachrichten

US, Japan and Netherlands in a squishy China chip ban

– Asia Times

The Wall Street Journal reported that

ASML of the Netherlands and Nikon of Japan would stop exporting “at least some immersion lithography machines” to China.

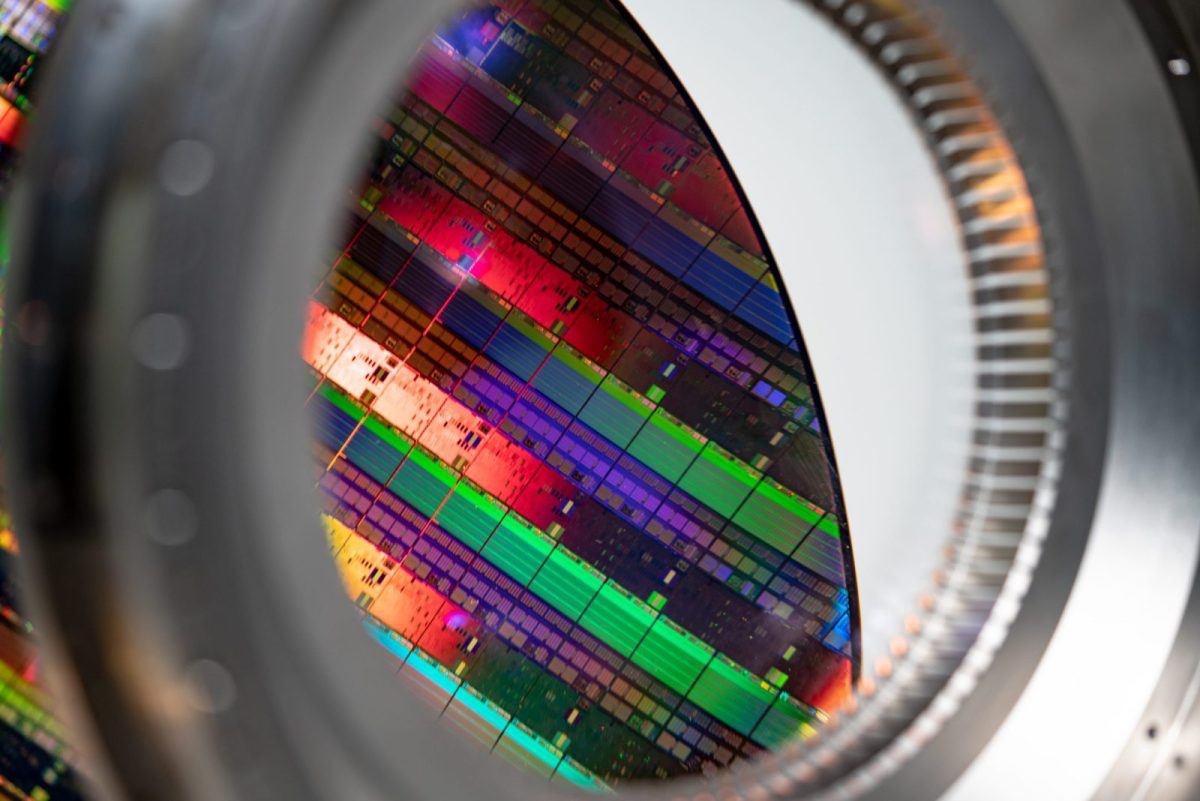

Immersion lithography means

DUV (deep ultra-violet) ArF (argon fluoride) laser lithography systems

in which the space between the final lens and the surface of the silicon wafer is filled with purified water.

Because purified water has a refractive index of 1.44 (compared with 1.0 for air),

this increases the resolution of the optics, facilitating the creation of smaller chip feature sizes.

At present, ASML and Nikon

are the only companies able to mass-produce these semiconductor-making machines.

Stopping shipments of ArF immersion lithography systems

would make it difficult for China to add new production capacity at or below the 40-nanometer node

– i.e., for the bulk of semiconductor production by value –

particularly at the 28nm and smaller nodes now used to produce

integrated circuits for automotive,

the Internet of Things,

consumer electronics,

mobile phones,

high-speed networking and computer applications.

The practical limit of DUV is 7nm.

The leading-edge 5nm and 3nm processes now in production at Taiwan’s TSMC and South Korea’s Samsung,

the 2nm processes they both have under development, rely on EUV (extreme ultra-violet) lithography systems.

These are made only by ASML and, at the request of the US government, not exported to China.

The semiconductor industry was surprised and US government officials were shocked

when it was reported last summer that China’s leading semiconductor foundry,

SMIC, had managed to produce chips using 7nm process technology.

Almost certainly, analysts say, this was accomplished by using ASML or Nikon equipment.

How many immersion lithography systems China has already purchased from ASML and Nikon is unclear,

but analysts’ estimates range from “many” to “dozens.”

Dylan Patel of SemiAnalysis reports that

SMIC, China’s leading foundry, “could achieve a capacity of well over 100,000 wafers a month of 7nm foundry capacity with their existing DUV tools alone.

This is higher than Samsung and Intel’s advanced node (<=7nm) foundry capacity, combined.”

“If all DUV tools at various Chinese nationals such as HuaHong, Shanghai Huali, YMTC, CXMT, GTA Semi, Nexchip, Yandong, Nexperia, CR Micro, Sien, Fulsemi, SEMC, NSEMI were reappropriated by SMIC,

the 7nm capacity they could build would far exceed that of even TSMC’s 7nm,” Patel claims.

China’s Shanghai Micro Electronics Equipment Co (SMEE) has reportedly

developed lithography equipment that works down to 14nm.

Yields appear to be low and mass production is not yet feasible,

but the technology is reportedly improving with time and experience.

To the extent that ASML and Nikon are forced to abandon the Chinese lithography market,

SMIC will have both a greater incentive and a greater opportunity to build a large-scale competitive business.

This is suddenly more important

now that the US has reportedly stopped granting licenses for the export of 4G smartphone chips and other previous-generation devices to Huawei.

For the time being,

Huawei should be able to buy them from MediaTek and other non-American sources, but US officials will no doubt try to put pressure on them as well.

https://asiatimes.com/2023/02/us-japan-and-netherlands-in-a-squishy-china-chip-ban/