AIST: Suppressing solar cell output drop: Preventing PID in megawatt-class solar power plants

Features of new technology:

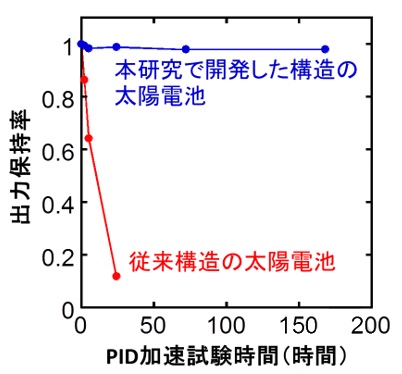

Sufficient suppression of “output drop caused by high voltage application” generated in megawatt class solar power plants

Easy technology transfer by simply covering the solar cell surface with a transparent and conductive film

Sufficient suppression of “performance degradation due to electrode disconnection of solar cell”

“AIST”: Photovoltaic Research Center

AIST’s Photovoltaic Research Center developed a technology that can sufficiently suppress voltage-induced degradation (PID: drastically reduced solar cells in a short period of time) by simply coating the solar cell surface with a transparent conductive film.

Voltage-induced degradation (PID is:

PID is a phenomenon in which the performance of a solar cell module is significantly reduced in a short period of time when a high voltage is applied.

In particular, it occurs frequently in megawatt-class solar power plants.

Conventional technology:

To date, the progress of PID has been slow, but not completely deterred.

There were also issues such as increased manufacturing costs and lower initial conversion efficiency.

The technology this time:

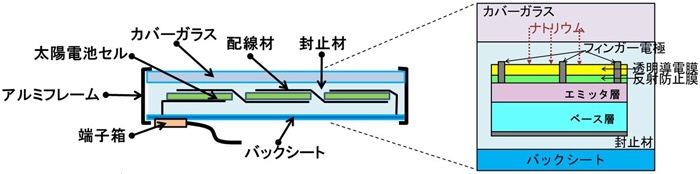

This is a technology that shields the electric field applied to the antireflection film by coating the conventional crystalline silicon solar cell (with an antireflection film on the surface) with a transparent conductive film.

PID can be sufficiently suppressed, and the risk of power generation decrease can be avoided.

This is an inexpensive and simple method that hardly reduces the initial conversion efficiency.

Until now, if the electrode on the surface of the photovoltaic cell was disconnected, the carrier at the location of the disconnection could not be collected.

However, with the cell developed this time, there is also the secondary effect that “carriers at the disconnection point can be collected through the transparent conductive film and the power generation performance does not decrease.”

In addition, the inexpensive solar cell materials and cell / module manufacturing processes that have been conventionally used can be used as they are.

The technology can be easily transferred to industry while maintaining the manufacturing cost.

https://www.aist.go.jp/aist_j/press_release/pr2019/pr20191217/pr20191217.html