South Korea: Semiconductor industry is in danger of decline:

-It is fatal to rely on Japan for materials and parts-

Foundry Trends:

Countries around the world are focusing on attracting the semiconductor industry in order to strengthen their growth potential.

TSMC:

The world’s largest foundry is building a state-of-the-art factory in the United States.

Sony Group:

TSMC will advance to Japan to build a factory and manufacture it jointly with the Sony Group.

Samsung Electronics:

As for South Koreans, Samsung Electronics has decided to make a huge investment in the United States.

Semiconductor Industry Association (SIA):

-A shocking report announced-

Chinese semiconductor device:

The world market share will reach 17% in 2024 from 9% in 2020.

It predicted that “in the future, the market share will be flat in South Korea.”

Korea’s core industry:

The semiconductor industry is the backbone of the Korean economy.

Ministry of Industry, Trade and Resources of Korea:

The total export value in 2021 is 644.54 billion dollars (73.85 trillion yen).

Semiconductor-related exports account for 128 billion dollars (14,670 billion yen).

The decline in the semiconductor business is directly linked to the devastating impact on the Korean economy.

China’s onslaught is not the only source of concern.

JoongAng Ilbo (Japanese electronic version):

Extremely dependent on Japan in the field of material parts and equipment.

As for semiconductor materials, it imports the largest amount of 38.5% from Japan.

High technology barriers, shortage of human resources, weak infrastructure, etc.

Problems with the Korean semiconductor industry were pointed out.

–zakzak: Yukan Fuji official website

https://www.zakzak.co.jp/article/20220124-S5DL3PH2FRIAZBAIMQV3P3IBCE/

Strengthening the Global Semiconductor Supply Chain in an Uncertain Era

– Semiconductor Industry Association

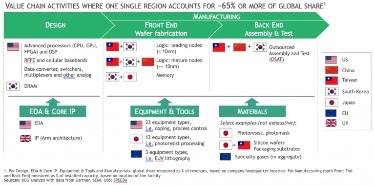

GEOGRAPHIC SPECIALIZATION HAS CREATED VULNERABILITIES IN THE GLOBAL SEMICONDUCTOR SUPPLY CHAIN.

There are more than 50 points across the value chain

where one region holds more than 65% of the global market share.

These are potential single points of failure

that could be disrupted by natural disasters, infrastructure shutdowns, or international conflicts, and may cause severe interruptions in the supply of essential chips.

About 75% of global semiconductor manufacturing capacity, for example,

is concentrated in China and East Asia, a region significantly exposed to high seismic activity and geopolitical tensions.

In addition,

100% of the world’s most advanced (below 10 nanometers) semiconductor manufacturing capacity

is currently located in Taiwan (92%) and South Korea (8%).

These advanced chips are essential

to America’s economy, national security, and critical infrastructure.