MHI’s TF coil: Shipped to French fusion DEMO reactor

-Europe, the United States, China, India, Russia, South Korea, and Japan participate-

-Europe and Japan jointly produce superconducting coil-

We provide a summary of Mitsubishi Heavy Industries’ timely disclosures.

MHI’s TF coil:

All five units were completed. This machine is scheduled to be shipped from Kobe Port in September.

MHI’s ITER equipment:

We will support the realization of fusion energy by designing and developing nuclear fusion prototype reactors such as the Mitsubishi Heavy Industries divertor.

Japan’s QST received an order from the experimental fusion reactor Eater (ITER).

The world’s largest superconducting coil:

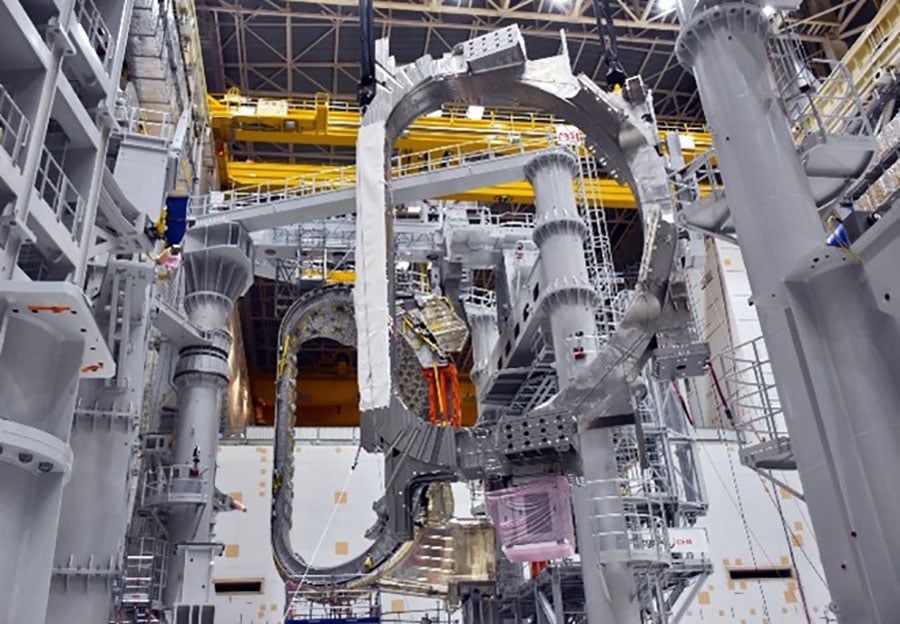

MHI has completed the final model of toroidal magnetic field coil (TF coil).

19 TF coils manufactured in Japan and Europe:

Nine of them will be manufactured in Japan and 10 in Europe.

Of these, MHI received an order to manufacture five units.

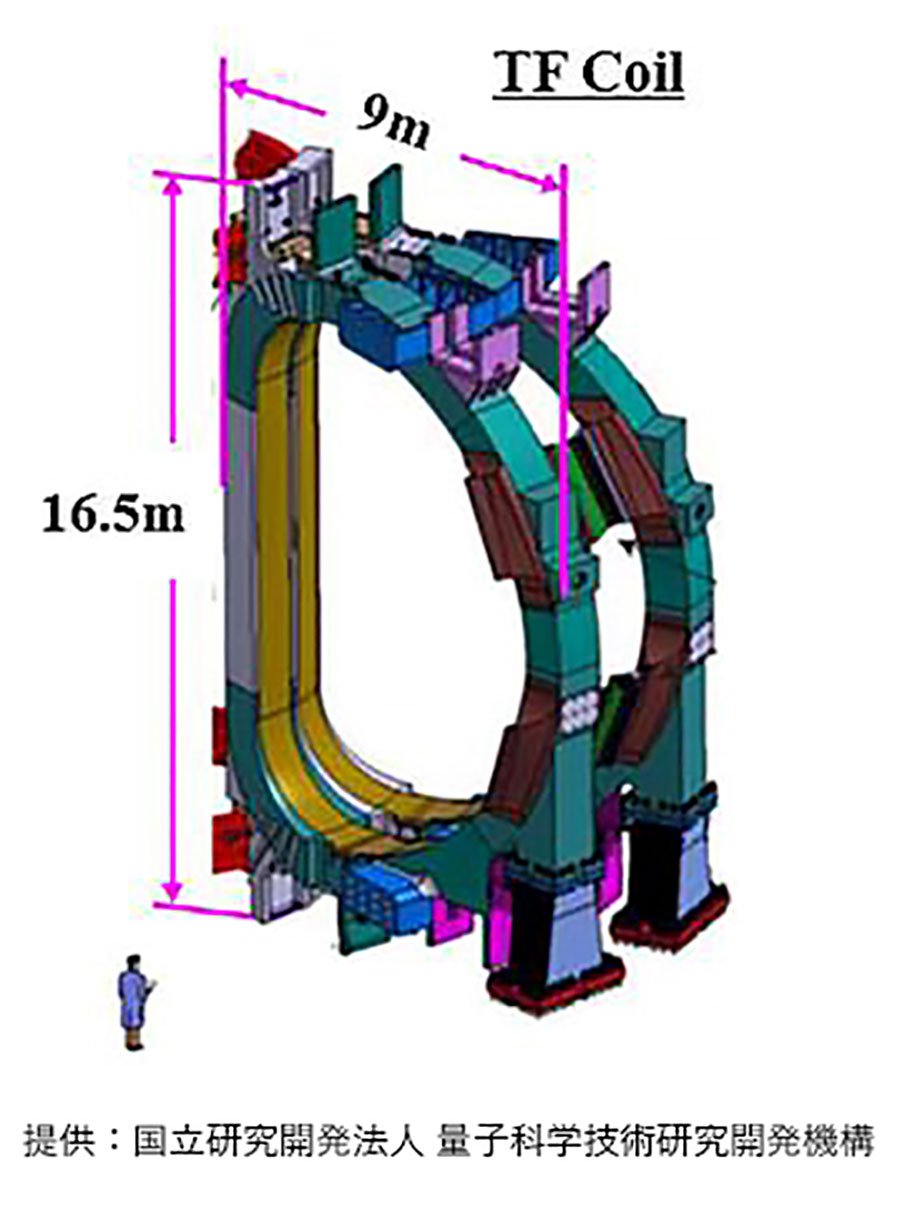

Inner structure of TF coil:

However, MHI’s Futami Factory will manufacture all internal structures for 19 units.

MHI’s TF coil completed:

In January 2020, MHI completed the first TF coil for ITER.

This time, four completed TF coils will be sequentially transported from Kobe Port to southern France.

Installation is underway on site. This machine is also scheduled to be shipped from Kobe Port within this month.

What is TF coil:

A gigantic superconducting coil with a height of 16.5m, a width of 9m, and a total weight of 300 tons.

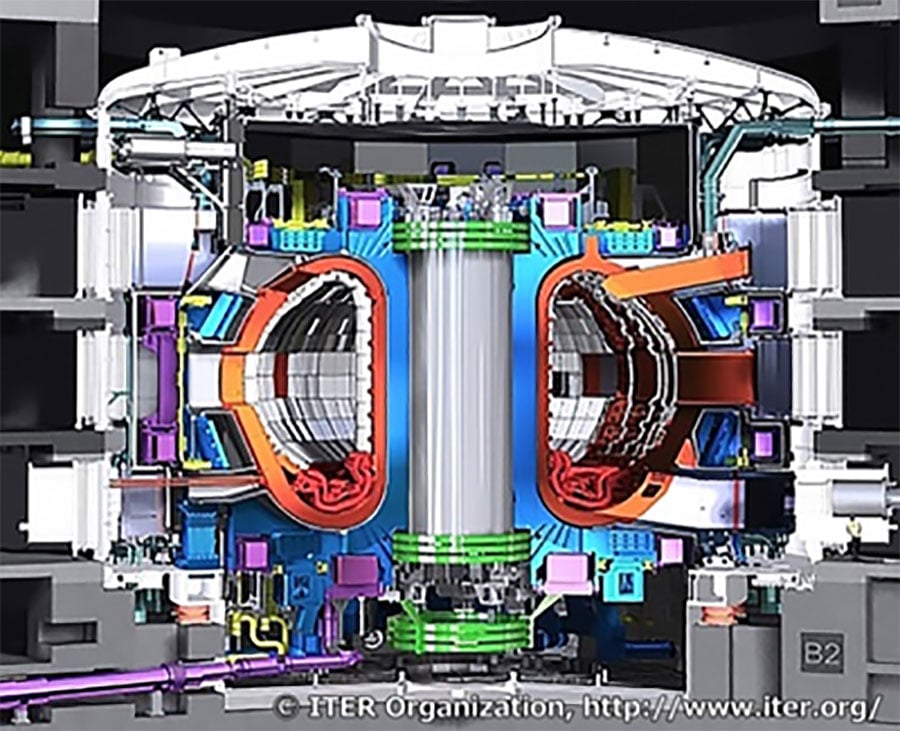

The TF coil for ITER will cause a nuclear fusion reaction inside the reactor.

Therefore, manufacturing precision of less than 1/10,000 is required.

MHI’s ITER equipment:

In addition to TF coils for the start of ITER operation,

Diverter (Note 1)

Horizontal launcher (Note 2)

We are working on the development and production of major equipment.

Development of nuclear fusion prototype reactor:

Furthermore, following the ITER project, construction of a nuclear fusion prototype reactor is planned.

MHI will also support the design and development of the fusion DEMO reactor.

What is the ITER project?

Conduct scientific and technical demonstrations toward the realization of nuclear fusion energy.

International project:

The seven regions participating are Japan, Europe, the United States, Russia, South Korea, China, and India.

ITER is under construction in Saint-Paul-les-Durance, France.

This time’s results:

Superconducting coils are absolutely essential for ITER.

A highly precise and high magnetic field (12 Tesla) is required for ITER’s plasma confinement.

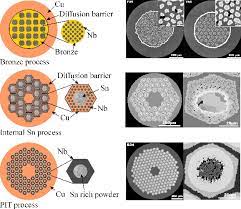

For this reason, the development of superconducting coils using niobium-tin superconductors is essential.

Maintaining operation in superconducting state:

It must operate at extremely low temperatures of -269 degrees Celsius.

A special stainless steel structural material that could withstand extremely low temperatures and its manufacturing technology were required.

ITER’s TF coil:

This is the world’s largest niobium tin superconducting coil ever.

QST and MHI:

In 2005, QST in Japan began researching TF coil manufacturing technology.

Since 2012, Mitsubishi Heavy Industries has been participating in the joint production of TF coils.

QST will promote procurement activities as the Japanese domestic organization for the ITER project.

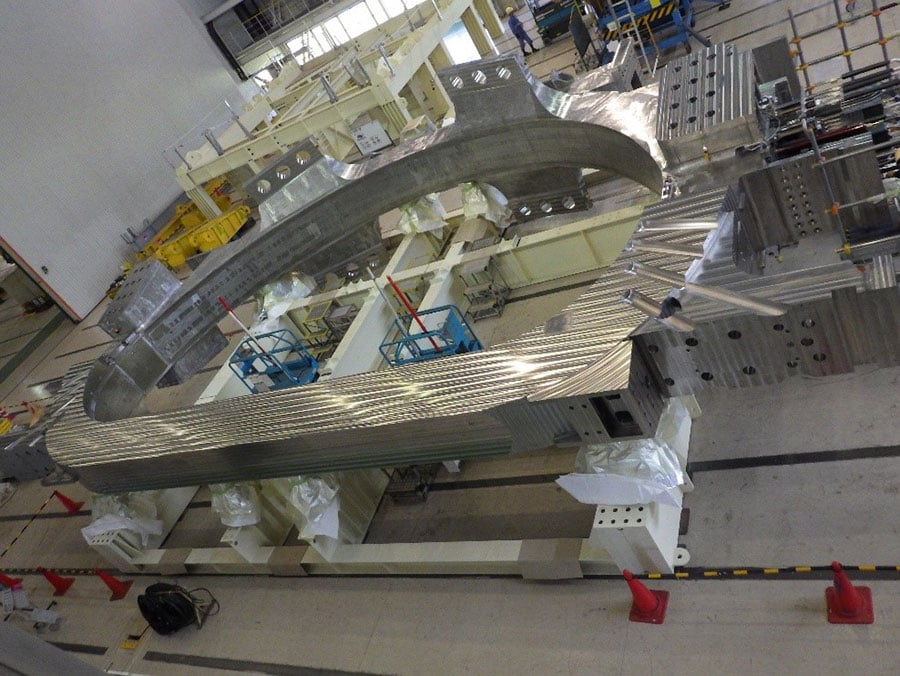

Niobium-tin superconductor winding:

Together, the two companies developed a technology for winding niobium-tin superconductors with high precision.

In addition, special stainless steel is used as the structural material to overcome durability at extremely low temperatures.

Furthermore, we devised a manufacturing method that suppresses deformation caused by welding.

As a result, we succeeded in manufacturing the high precision TF coil required by ITER.