Aichi Steel: Magnetic particle, single crystallization with higher magnetic force: Dysprosium-free magnet

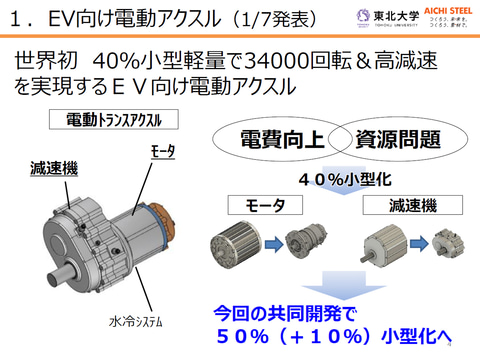

Aichi Steel and Tohoku University:

On February 9, we announced the improvement of the performance of magnetic powder, which is the core material of Dy (dysprosium) -free bond magnet “Magfine”.

Aichi Steel has “improved the performance of electric axles for EVs announced in January by 10%.”

Further miniaturization and cost reduction become possible.

Higher performance of magnetic force of magnetic powder:

The magnetic force of the magnetic powder used in the Dy-free bond magnet “Magfine”, which is a product of Aichi Steel, has been further improved.

Tohoku University Advanced Analysis Technology:

In the development of magnetic powder, the detailed structure of the magnet was elucidated by the advanced analysis technology of Tohoku University.

Based on this knowledge, we proceeded with the development of magnets under various conditions at Aichi Steel’s magnetic particle manufacturing equipment.

Two points of development:

The magnet powder structure, which was polycrystalline, was single-crystallized.

And it is a highly oriented technology by hydrogen treatment.

What is single crystallization?

I want one powder to be one crystal.

In order to achieve the ideal, the hydrogen crushing conditions were optimized and single crystal formation was realized.

What is highly oriented technology?

High-performance magnet powder is obtained by “performing heat treatment in a controlled hydrogen atmosphere”.

In the “d-HDDR processing” process,

Optimize control parameters

What used to be 75% oriented,

The orientation of the microcrystal grains was aligned as the 80% orientation.

Development results:The magnetic force of the magnet powder has increased to 115 this time, assuming that the conventional value is 100.

The holding power is almost maintained at 103 this time, assuming that the conventional one is 100.

By using high-performance magnetic powder, the entire electric axle is 10% smaller than before.

Scheduled to be sold:Regarding the magnetic powder with higher performance this time, we will build a mass production system by the end of 2021 and start providing it as magnetic powder.

Car Watch

https://car.watch.impress.co.jp/docs/news/1305760.html

Succeeded in improving the performance of Dy-free Nd-based anisotropic magnet powder that contributes to the spread of electric vehicles

~ Achieving further miniaturization and weight reduction of electric axles for EVs ~

Professor Satoshi Sugimoto of Tohoku University and Aichi Steel Co., Ltd.

https://www.aichi-steel.co.jp/news_item/20210209_release.pdf