Toray: Developed ultra-thin graphene dispersion: Battery life, 1.5 times longer than CNT!

Toray:

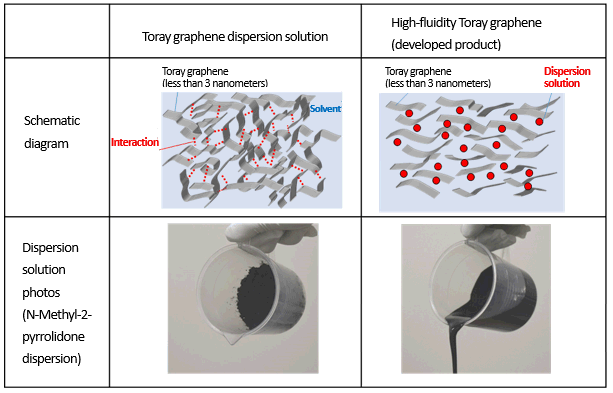

On March 8, it announced that it had developed an ultra-thin graphene dispersion (photo) that has both high concentration and high fluidity.

Ultra-thin graphene dispersion:

When used as a conductive auxiliary agent for EV batteries

Compared to using carbon nanotubes

It was confirmed that the battery life was improved by 1.5 times.

Battery life improved 1.5 times:

Toray is preparing for mass production and aims for sales of 10 billion yen in 2030.

New switch

Toray Creates Ultra-Thin Graphene Dispersion Solution Offering Outstanding Fluidity and Conductivity

Tokyo, Japan, March 8, 2021

Toray Industries, Inc.,

announced today that it has developed an ultra-thin graphene (see glossary) dispersion solution with excellent fluidity and electrical and thermal conductivity.

Applications

that could benefit significantly from the solution include battery and wiring materials and paints.

Toray will keep pushing ahead with R&D on this breakthrough to accelerate commercialization.

material for lithium-ion batteries.

A good application with the new solution would be as a conductive material for lithium-ion batteries.

It can be mixed easily with cathode material, with graphene inserted between cathodes to boost conductivity.

This approach

lowers capacity losses from conductive pathways degrading during repeated charging and discharging, thereby extending battery life.

The high-performance batteries of electric vehicles conventionally employ carbon nanotubes as conductive agents.

Toray testing confirmed that the new solution offers 50% better battery life than carbon nanotubes.

NEWS | TORAY

https://cs2.toray.co.jp/news/toray/en/newsrrs02.nsf/0/80C3B968C27401B549258692001CB737?open

Northeast Asian Countries Competing in EV Battery Separator Industry

The current industry leaders are SK ie technology, Asahi Kasei and Toray.

SK ie technology entered the industry in 2003, when the two Japanese companies were already dominating it.

SK

is currently building additional facilities in China and Poland to reach an annual production capacity of 1.87 billion square meters in three years.Toray

is also expanding its facilities in Hungary to increase its capacity by 20 percent to 1.5 billion square meters.Semcorp,

the largest separator manufacturer in China,announced last year that it would build a factory with an annual capacity of 400 million square meters in Hungary and its total annual supply would reach 2.8 billion square meters in 2023.

Businesskorea

http://www.businesskorea.co.kr/news/articleView.html?idxno=62287