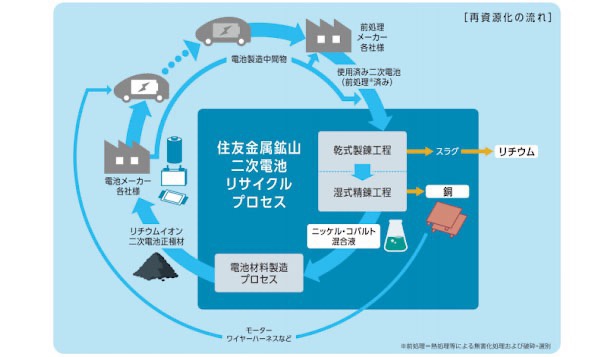

Flow of recycling (source: Sumitomo Metal Mining)

Sumitomo Metal Mining: Cathode materials made from recycled materials!

-Passed the performance test of a Toyota battery subsidiary-

ーRecovering Nickel and Cobalt from Automotive LiBs to Manufacture Cathode Materialsー

Report from Nihon Keizai Shimbun, the latest article

Sumitomo Metal Mining:

On the 22nd, cathode materials were manufactured using rare metals recovered from used LiBs.

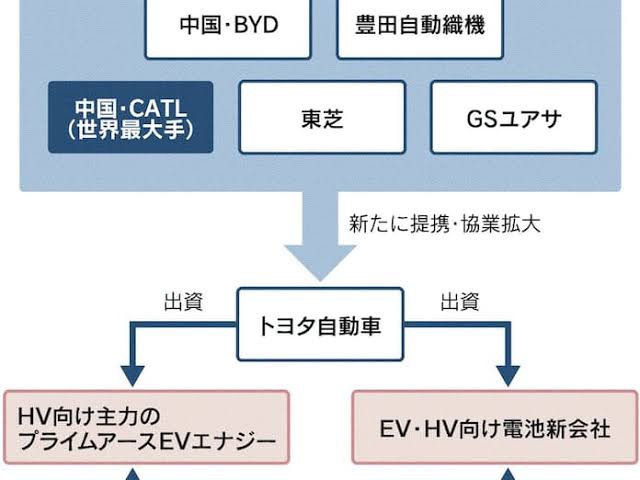

This positive electrode material passed the “Performance Test of Toyota’s Battery Subsidiary”.

Until now, there have been concerns that “recycled cathode materials are inferior in battery capacity.”

Recycled cathode materials (provided by Sumitomo Metal Mining)

Mass production of recycled cathode materials:

There will be a shortage of rare metals used in batteries in the future.

Sumitomo Mining aims to mass-produce recycled cathode materials.

Sumitomo Metal Mining recovered nickel and cobalt from in-vehicle LiBs and manufactured cathode materials.

Toyota Subsidiary Primearth EV Energy:

Primearth EV Energy has prototyped a battery using the positive electrode material.

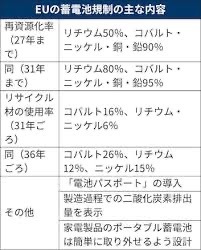

European Union recycling regulations:

Introduce regulations that require the use of recycled rare metals in storage batteries.

The importance of metal recycling for batteries is increasing.

https://www.nikkei.com/article/DGXZQOUC227YP0S3A620C2000000/