JFE Steel: New endless rolling technology: Developed high-tensile bonding equipment

-Start mass production-

JFE Steel:

On May 6, 2021, we developed the world’s first hot continuous rolling (endless rolling) technology for high-strength steel sheets (HITEN).

We have already used new technology for mass production at the Atsunobu Plant of East Japan Works in the Chiba area.

Achieved stable high-tensile production and improved productivity.

Conventional problems:

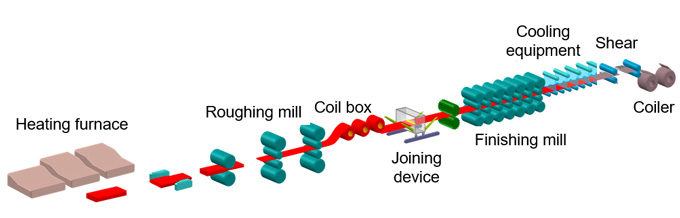

In the conventional hot rolling process, the rough rolling mill and the finishing rolling mill are used.

Roll the heated slabs one by one,

After controlling the temperature with the cooling equipment

It had to be wound into a coil.

However, in this method, tension is not applied to the tip and tail ends of the coil during rolling.

In addition, there is a problem that the shape of the steel sheet deteriorates and meandering occurs.

This time, we developed a joining device:

A joining device was installed between the rough rolling mill and the finishing rolling mill.

Developed a device to join the tip and tail ends of the coil,

Multiple coils can be continuously charged into the rolling mill

Developed the world’s first endless rolling technology.

Introduced at Nippon Steel Works.

JFE Steel | fabcross for engineer

https://engineer.fabcross.jp/archeive/210507_jfe-steel.html

JFE Steel Develops Hot-continuous Rolling Process for HITEN

May 6, 2021

JFE Steel Corporation

JFE Steel Develops Hot-continuous Rolling Process for HITEN JFE Steel Corporation

announced today that it has developed the world’s first hot-continuous-rolling (endless-rolling) process for high-tensile-strength steel sheets (HITEN).

Mass production

has already started at the hot-rolling mill of JFE Steel’s Chiba facility, part of the company’s East Japan Works, for the highly stable and productive manufacturing of high-tensile steel.

In 1996, JFE Steel

developed the world’s first endless-rolling process (Fig. 1) in which the leading and trailing ends of adjacent sheets

that have been wound into coils are joined after roughing, which allows the coils to be inserted continuously into the finishing mill.

The endless-rolling process has been deployed at JFE Steel’s Chiba facility.

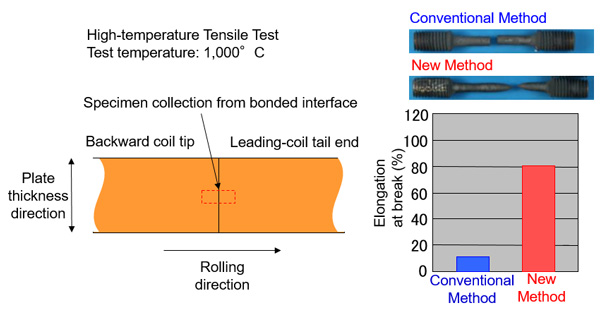

In the case of HITEN, however,

joint strength and ductility are reduced due to elements such as silicon and manganese being added to improve the mechanical characteristics of these steel products.

JFE Steel has now developed technology for maintaining joint strength and ductility (Fig. 2) and suppressing breakage during finish rolling.

As a result, endless rolling of high-strength steel has become possible, contributing greatly to the highly stable and productive manufacturing of high-tensile steel through improved threading performance.

JFE Steel Corporation