JFE钢铁:新型连续轧制技术:开发高强度粘合设备

-开始量产-

JFE钢铁:

2021年5月6日,我们开发了世界上第一项用于高强度钢板(HITEN)的热连续轧制(连续轧制)技术。

我们已经在千叶地区东日本工厂的厚信工厂使用了新技术进行批量生产。

实现了稳定的高张力生产并提高了生产率。

常规问题:

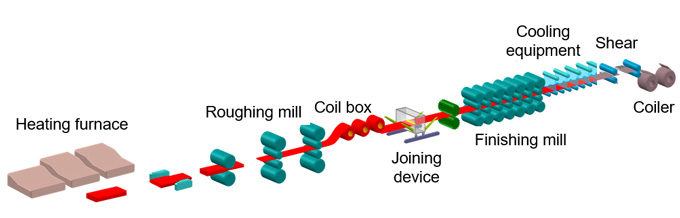

在常规的热轧工艺中,使用粗轧机和精轧机。

一块一块地加热加热的板,

用冷却设备控制温度后

它必须缠绕成线圈。

但是,在这种方法中,在轧制过程中张力不会施加到线圈的前端和后端。

另外,存在钢板的形状劣化而产生弯曲的问题。

这次,我们开发了一种连接设备:

在粗轧机和精轧机之间安装了连接装置。

开发了一种装置来连接线圈的末端和末端,

可以将多个卷材连续装入轧机

开发了世界上第一个无尽的轧制技术。

介绍给东日本工厂。

JFE Steel |工程师的Fabcross

https://engineer.fabcross.jp/archeive/210507_jfe-steel.html

JFE Steel Develops Hot-continuous Rolling Process for HITEN

May 6, 2021

JFE Steel Corporation

JFE Steel Develops Hot-continuous Rolling Process for HITEN JFE Steel Corporation

announced today that it has developed the world’s first hot-continuous-rolling (endless-rolling) process for high-tensile-strength steel sheets (HITEN).

Mass production

has already started at the hot-rolling mill of JFE Steel’s Chiba facility, part of the company’s East Japan Works, for the highly stable and productive manufacturing of high-tensile steel.

In 1996, JFE Steel

developed the world’s first endless-rolling process (Fig. 1) in which the leading and trailing ends of adjacent sheets

that have been wound into coils are joined after roughing, which allows the coils to be inserted continuously into the finishing mill.

The endless-rolling process has been deployed at JFE Steel’s Chiba facility.

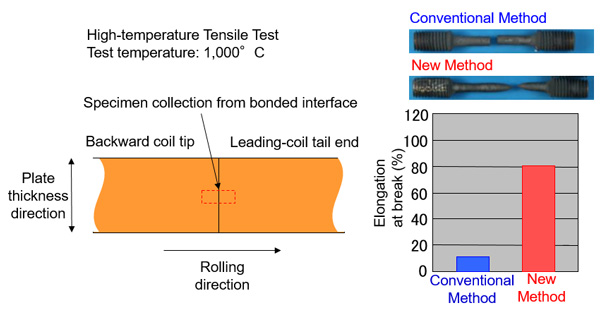

In the case of HITEN, however,

joint strength and ductility are reduced due to elements such as silicon and manganese being added to improve the mechanical characteristics of these steel products.

JFE Steel has now developed technology for maintaining joint strength and ductility (Fig. 2) and suppressing breakage during finish rolling.

As a result, endless rolling of high-strength steel has become possible, contributing greatly to the highly stable and productive manufacturing of high-tensile steel through improved threading performance.

JFE Steel Corporation