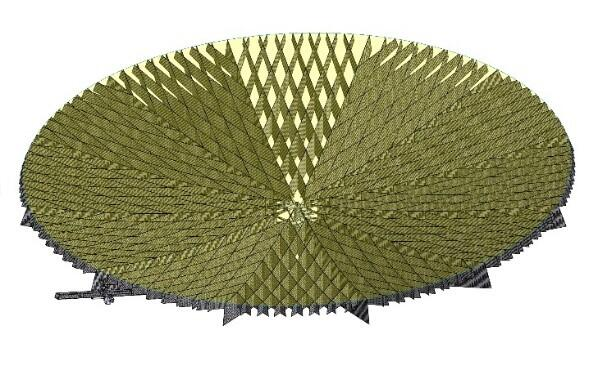

JAXA: Developed metal mesh for unfolding reflector: Small SAR (Synthetic Aperture Loader)

-Use of new materials, cost reduction-

JAXA,

Solar wire mesh,

NGK,

Techno solver,

Koyo Materica

On January 26, it announced that it had jointly developed a metal mesh for a deployable reflector mounted on an artificial satellite.

Next-generation satellite communication:

In order to increase the communication speed, “a large retroreflector that can handle high frequencies is indispensable.”

Conventional metal mesh:

The conventional metal mesh uses gold and molybdenum.

The bottleneck was that the materials were expensive and difficult to obtain.

In response to this, the five companies jointly proceeded with the development of a new metal mesh.

This metal mesh:

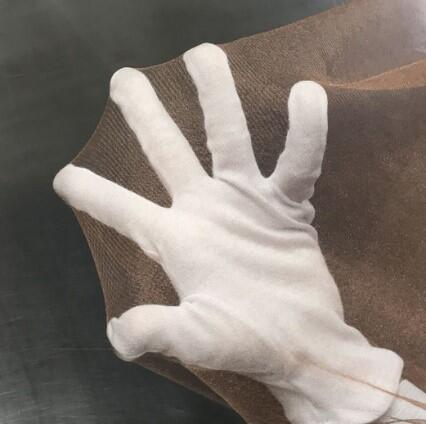

It was made of zirconium copper as a wire and was manufactured by flexible tricot knitting.

High strength and light weight

In the high-speed communication ka band (30 GHz band),

Has good reflection characteristics.

Manufactured from a new material using zirconium and copper, which are easily available and inexpensive.

Achieves a significant cost reduction compared to conventional products.

Small SAR (Synthetic Aperture Loader):

Next-generation communication satellites and

Small SAR (Synthetic Aperture Loader) satellite, etc.

It is expected to be used for commercial satellites.

Taiyo Wire Mesh and 3 other companies:

Commercialized the same metal mesh for commercial satellites.

Plan to promote sales.

(Steel Newspaper) –Yahoo! News

https://news.yahoo.co.jp/articles/bc0f7b0115772266d94774be95ca429ea71a2bff

JAXA | develop a metal mesh for onboard deployable reflectors

January 26, 2021 (JST)

Taiyo Wire Cloth Co., Ltd

NGK Insulators, Ltd.

Technosolver Corporation

Koyo Materica Corporation

JAXA

have jointly developed a metal mesh for onboard deployable reflectors that has achieved a dramatic cut in costs.

faster communications speeds

In order to realize faster communications speeds, next generation communications satellites need to be able to work with high frequency band, which necessitates large deployable reflectors.

Conventionally, the metal mesh of the antennas have been made from gold plated Molybdenum wire,

which is a mixed metal of precious metal and rare metal and therefore difficult to obtain and very costly.

To cut costs, the five organizations have jointly developed a new metal mesh.

The new metal mesh

is made from Zirconium Copper wire and fabricated by tricot weaving.

It is light weight, flexible, and has excellent electrical reflection properties at the high frequency band of Ka (30 GHz).

Zirconium Copper wire

has characteristics similar to Molybdenum wire and is applicable to metal mesh.

On top of this, Zirconium Copper wire is strong enough to be fabricated into a metal mesh without gold plating.

These two reasons

make it possible to dramatically cut cost compared with conventional metal mesh.

The new metal mesh

is expected to be applied primarily to next generation communications satellites and SAR (synthetic apature radar) satellites, both of which use deployable reflectors to improve satellite capabilities.

Taiyo Wire Cloth Co., Ltd, and three other corporations

are planning to make the new metal mesh available on the market for commercial satellites.

https://global.jaxa.jp/press/2021/01/20210126-1_e.html

Joint development of metal mesh for satellite-mounted retroreflector