Japan: World Semiconductor Manufacturing Ranking: Importance of Materials and Equipment Technology

-Fourth quarter of 2020-

Smartphone shipments

First place is Apple.

Second place is Samsung

3rd place is Xiaomi,

4th place is OPPO,

5th place is Huawei

With the exception of Apple, China and South Korea are overwhelmingly strong, and there is no Japan’s figure.

Raw materials for smartphones: Global market share of 3 items

In 2019, export control regulations for three items to South Korea were tightened.

Polyimide fluoride,

Resist,

Hydrogen fluoride,

However, regarding the global market share of three items for smartphone manufacturing,

Japan’s market share is overwhelmingly large at 70-90%.

It far exceeds the “share of smartphone assembly and production in China and South Korea”.

Global market share of silicon wafers:

Of course, Japan’s overwhelming share is not limited to the above three items.

Silicon wafer manufacturer indispensable for semiconductor manufacturing

First place is Shin-Etsu Chemical

Second place is SUMCO (formerly Mitsubishi Sumitomo Silicon)

These two companies alone account for 50% of the world market share.

By the way,

Third place is Taiwan’s Global Wafers

4th place is Siltronic, Germany

5th place is Korea SK Schiltron,

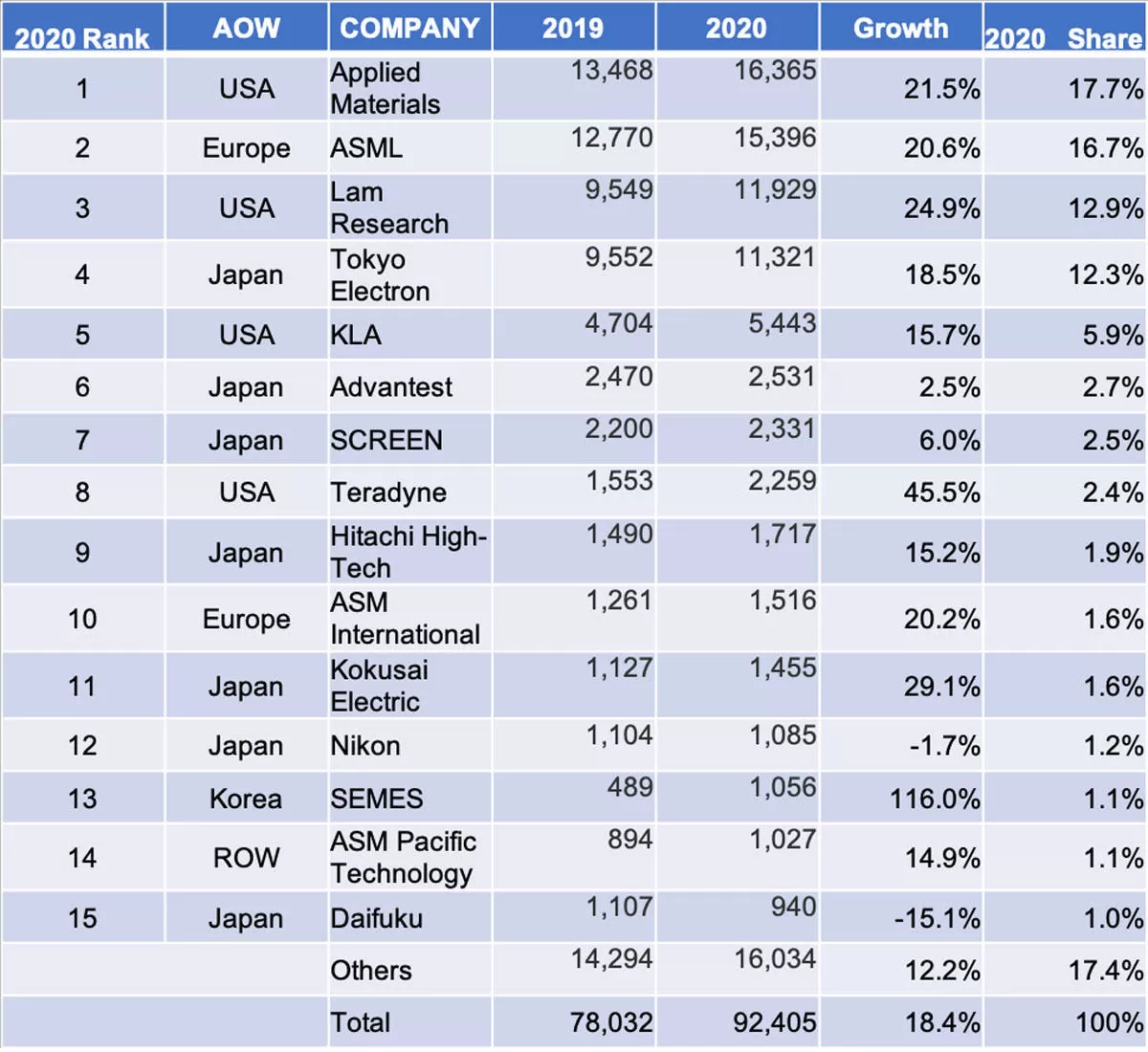

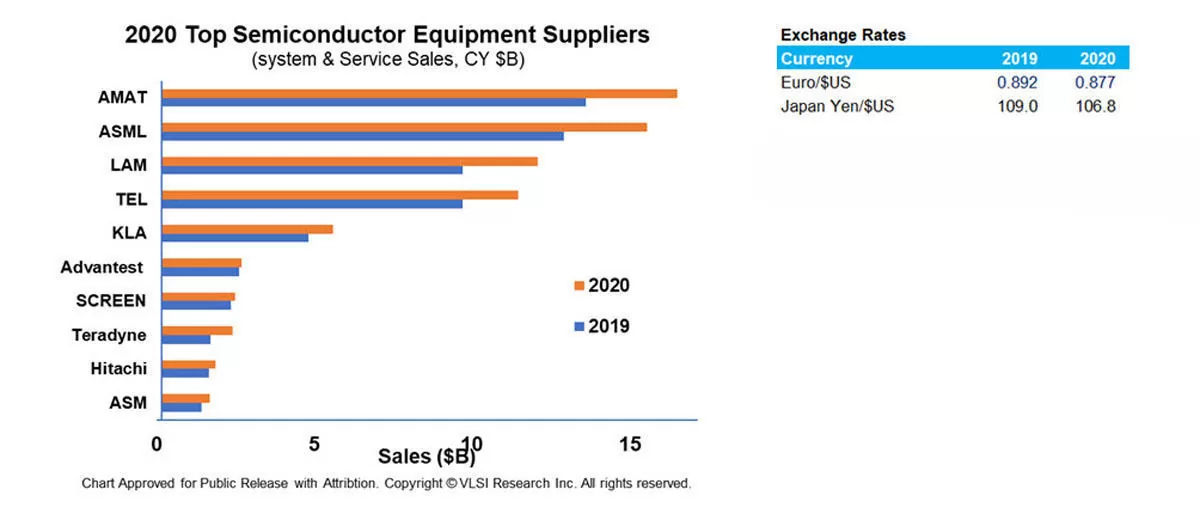

Global market share of semiconductor manufacturing equipment:

In addition, 4 Japanese companies are among the top 10 semiconductor manufacturing equipment.

Tokyo Electron,

Advantest,

SCREEN Holdings,

Hitachi High-Tech Top,

Of the 15 companies, there are a total of 7 companies in addition to the above 4 companies.

Kokusai Electric (under KKR Fund),

Nikon,

Daifuku,

15 semiconductor manufacturers:

There are 15 major semiconductor manufacturers in the world.

About half are Japanese.

Most of the others are of Western origin.

rarely see China and South Korea.

Miraial:

Large-diameter wafers with a diameter of 300 mm for advanced processors and memories hold a 40% share.

Miraial’s shipping container is made of polycarbonate.

For semiconductors manufactured at the nano level, even a very small amount of fine particles poses a big problem.

Therefore, even in the case of silicon wafers distributed, high quality is required.

Need for Japan’s hardware:

Advanced software only works on high-performance hardware.

No matter how high-performance software is born,

If there is no high-performance hardware that supports the high-performance software,The high-performance software is nothing more than useless.

High-performance software:

Digital data is extremely vulnerable.

Anyone can easily copy data.

Therefore, it spread rapidly all over the world.

High performance hardware:

However, “high-performance hardware semiconductor manufacturing technology” is completely different.

“Development of semiconductor manufacturing technology does not make sense, so it is a process of trial and error.”

Software:

It is natural that software “works according to the built program”.

Hardware:

It is natural that the hardware of the semiconductor manufacturing industry “even if it is manufactured according to reason, it usually fails”.

By accumulating the endless mistakes,

An “analog-like” method that approaches completion is important.

Nano-level semiconductor manufacturing technology:

In other words, nano-level semiconductor manufacturing technology is extremely advanced.

“Accuracy to handle one molecule / atom is essential”.

“This microfabrication technology is Japan’s specialty.”

This “analog technology” cannot be copied and stolen.

Advanced manufacturing tech copy, plagiarism :

In the case of software, once the data is taken out by one engineer, it is the end of consistency.

However, advanced manufacturing tech exists “within the analog frame of’manufacturing process itself'”.

Even if “one or two engineers are pulled out”, it cannot catch up with Japan’s advanced manufacturing tech.

Introducing “Hydrogen Engine”:

The “hydrogen engine” is now in the limelight.

“Foreign countries cannot catch up with Japan with hydrogen engines” because “in fact, it is analog tech.”

The principle of the “hydrogen engine” is completely different from that of the fuel cell vehicle = “FCV” that uses the same hydrogen.

After all

Japan has “an extremely important treasure sword “.

“We don’t have to be pessimistic about the future of the manufacturing industry as a whole.”

Modern business