JX Metal: Pure copper powder for metal 3D printers: 99.94% relative density achieved

–Electron beam method: Realized 99.94% relative density-

–Laser beam method: Achieves a relative density of 98.56%-

JX Metal:

Conventionally, the problem was that the objects made with metal 3D printers are insufficient in density.

JX Metals has developed “Pure Copper Powder for Metal 3D Printers” that can solve this problem.

In the future, we plan to start providing sample products by the beginning of 2020.

Conventional problems:

There are still many technical challenges in the production of metal powder for metal 3D printing materials.

In particular, “3D printing using pure copper powder has a low relative density of the shaped object” was a bottleneck.

New product: (See Fig. 1)

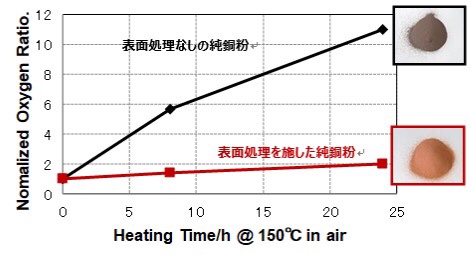

The newly developed product has been treated with a special surface treatment to prevent oxidation of the surface.

Using this special surface-treated copper powder, modeling with the electron beam method achieved 99.94% relative density.

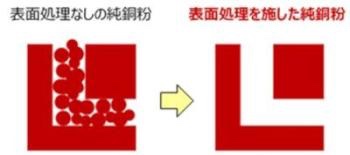

Suppression of pre-sintering: (See Fig. 2)

In addition, pre-sintering (adhesion between copper fine powders during molding / pre-process / pre-heating process) was suppressed (* 2)

This effect makes it possible to create fine, complex and highly flexible models.

Laser metal deposition method:

In addition, high results of 98.56% relative density have been obtained even with laser metal deposition.

Future fields of use:

In the future, taking advantage of these excellent characteristics of the newly developed product

Server heat spreaders,

Such as water cooling units for automobiles,

We hope that it can be used for various purposes.

Our lineup:

Titanium-based alloy powder: Group company Toho Titanium Tohotec

Tantalum and niobium alloy powder: H.C. Starck Tantalum & Niobium

The newly developed pure copper powder will be exhibited at Makuhari Messe “6th High Performance Metal Exhibition” from December 4th to 6th.

News Release | JX Metals