Iwatani: Mass production of “Lotus Metal”: Extremely high cooling 、heat dissipation performance

Iwatani / Lotus Thermal Solution

Iwatani Corporation and Lotus Thermal Solution have started joint research and development for the mass production of “Lotus Metal (porous metal)” with high heat dissipation performance.

The development base of Lotus in Kobe will be moved to Iwatani Central Research Laboratory to establish mass production technology.

Lotus / Osaka University venture

Lotus is a venture from Osaka University.

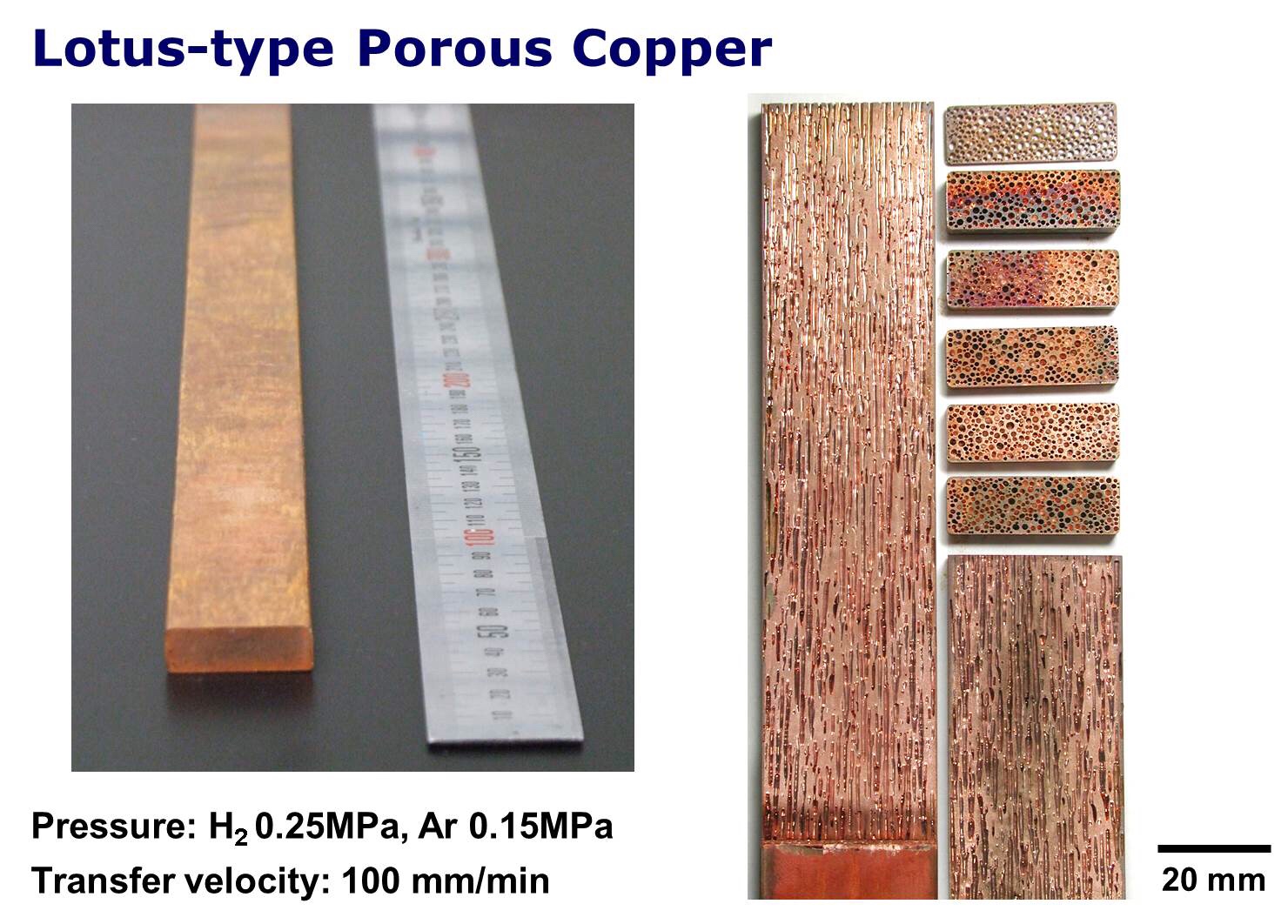

We have the technology to cast metal with lots of fine pores (“Lotus metal”).

“Lotus metal”: Casting technology

Dissolves molten metal such as copper and hydrogen gas and cools it by a special method.

The cross section of “Lotus Metal” is a structure in which the pores communicate in a pipe shape.

“Lotus metal” is a material that can increase the surface area and has extremely high cooling performance and heat dissipation performance.

The Company has invested in Lotus since July 2016 (our investment ratio is 7.4%)

We have conducted market research in various fields to develop applications that take advantage of the characteristics of Lotus Metal.

Three areas: Practical study

Under such circumstances, attention has been paid to the study of practical application in the following three fields.

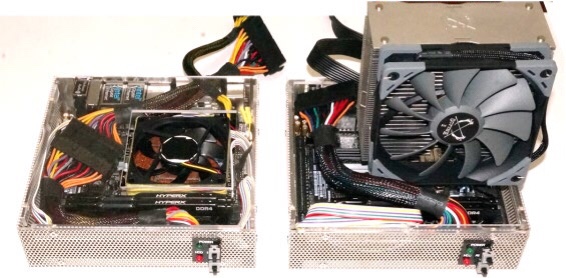

1) Cooling high-performance CPU: Supercomputers and large servers

With the increase in data processing volume, the CPU clock speed is increasing dramatically.

CPU cooling efficiency is a challenge for capacity improvement.

Using a Lotus metal cooler saves 80% in space compared to conventional coolers.

2) Cooling industrial machinery: Air cooling

By using a Lotus metal cooler, it is possible to handle even air cooling.

This has the effect of eliminating the need for cooling water.

3) In-vehicle inverter cooling for EVs

Electronic and electric vehicles are evolving.

Equipped with high-performance semiconductor chips and batteries and electric circuits that consume power.

Now, it is attracting attention as a compact cooler.

http://www.iwatani.co.jp/img/jpn/pdf/newsrelease/1339/20191219_news_jp1.pdf

Lotus Materials Laboratory Co., Ltd.

Research and development of porous metal “Lotus metal”

Invented the world’s first continuous casting method for Lotus metal mass production.

Basic manufacturing patents have been obtained in 14 countries around the world.

Lotus Materials Research Laboratories is the only company in the world that has the technology to mass produce Lotus metals.

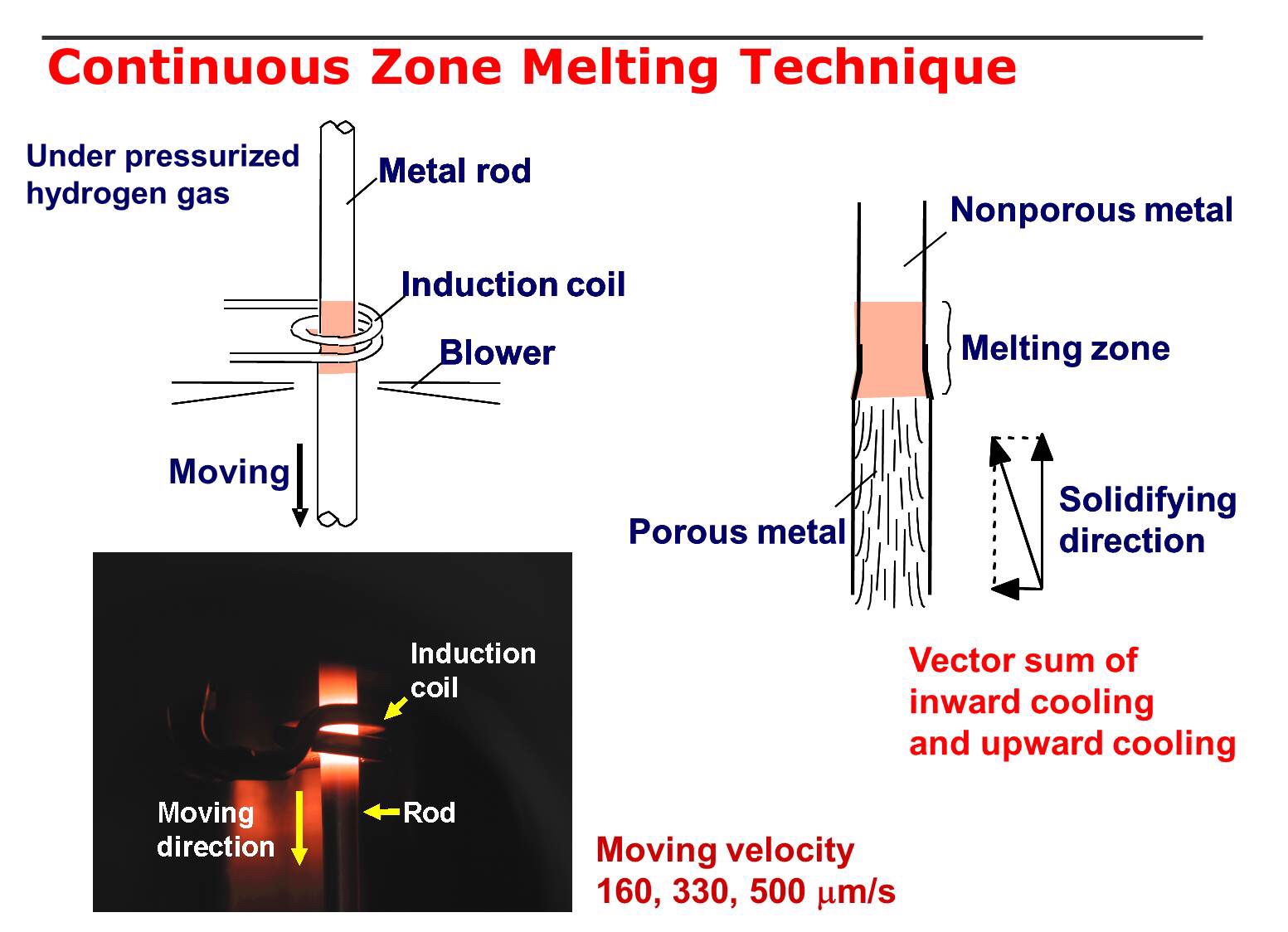

Fabrication Techniques of Lotus Metals using Gas

Lotus metals are fabricated by pore formation of insoluble gas when the molten metals dissolving gas are solidified during unidirectional solidification.

Three fabrication techniques were developed by Nakajima group: mold casting technique, continuous zone melting technique and continuous casting technique.