Nihon Keizai Shimbun (July 5th):

Toyota reforms production with EV, halving process and factory investment.

An article titled Adoption since 2016 was posted.

Toyota’s “Gigacast”:

The new production technology “Gigacast” will be adopted for EVs to be released in 2026.

Adopt a self-propelled system that does not use a belt conveyor.

These technologies will reduce the production process and factory investment by half.

What is Gigacast:

We manufacture huge body parts that are integrally molded with aluminum casting equipment.

Significantly reduce the number of parts and production processes.

It will be installed in the next-generation EV in 2026.

Toyota’s next-generation EV:

The car body is divided into three parts: front, center and rear.

Gigacast is used in the rear and front.

For the rear part of the vehicle body, the conventional 86 parts / 33 processes will be integrated into 1 part / 1 process.

For the front part of the vehicle body, the number will be reduced from 91 parts / 51 processes to 1 part/ 1 process.

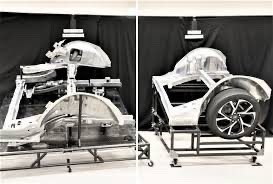

Rear parts of the EV “bZ4X”:

Currently, the EV “bZ4X” is manufactured with 86 parts and 33 processes.

Consolidate rear parts into one part and one process.

With this, we aim to significantly cut the wages for on-site assembly.

https://hisayoshi-katsumata-worldview.com/archives/32730670.html