The University of Tokyo, Shimizu: Mixing CO2 with waste concrete Regeneration: Practical use in 2030

-Development of basic technology for practical use in 2030-

The University of Tokyo, Shimizu Corporation, Taiheiyo Cement:

May 19th

The company announced that it has developed the basic technology for “calcium carbonate concrete (CCC)” that recycles used concrete.

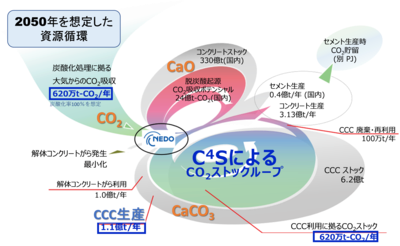

This is an epoch-making technology that regenerates used concrete by mixing carbon dioxide (CO2) in the air.

CO2 emission reduction:

“CO2 emitted in the manufacturing process of existing concrete” is fixed.

It can also contribute to reducing CO2 emissions.

It will be put into practical use in 2030, aiming for widespread use in 2050.

Replace with CCC:

If the conventional cement and concrete are replaced with CCC, half of the total concrete production will be CCC around 2050.

resulting in:

20 million tons of CO2 emissions reduced annually,

It will be possible to fix 6.2 million tons of CO2 annually.

Traditional wall:

Cement, which is a raw material for concrete, emits a large amount of CO2 at the production stage.

However, “utilization of dilute CO2 emitted during concrete production” was difficult.

The Daily Engineering & Construction News

https://www.decn.co.jp/?p=119729

Faculty of Engineering, University of Tokyo | World’s First!

Developed basic manufacturing technology for completely recyclable carbon-neutral concrete made from CO2

-NEDO Moonshot R & D Project “C4S R & D Project”-

https://www.t.u-tokyo.ac.jp/foe/press/setnws_202104151058544435600863.html