Mitsubishi’s MELSUSMO: high efficiency without permanent magnets

-Energy efficiency and resource saving better than IPM motors-

-Realization of “IE5” with high-efficiency motors-

We will deliver a summary from the article published in Newswitch.

Mitsubishi Electric Motors:

MELSUSMO,

a high-efficiency synchronous reluctance motor (SynRM),was released in May.

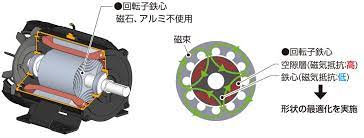

Conventional IPM (embedded magnet) motor:

Until now, IPM motors have been used as industrial motors.

The IPM motor used to be synonymous with high efficiency and energy saving.

Develop SynRM:

MELSUSMO realized resource saving

in addition to the same energy efficiency as IPM.

Since the release of SynRM, steady inquiries have continued.

Energy efficiency and resource saving:

The world’s industries aim to achieve carbon neutrality (CN) by 2050.

Mitsubishi Electric’s “MELSUSMO”:

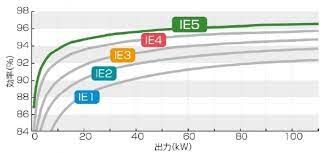

Mitsubishi Electric achieved “IE5” with “MELSUSMO”.

The rotor core shape of the motor has been optimized through a dedicated design.

We succeeded in achieving both high efficiency and rotor strength.

What is “IE5”:

An international high-efficiency standard

for industrial motors with an output of 15 kw or less.

It is the world’s highest level standard.

Nagoya Works Shinshiro Plant:

The energy saving performance of MELSUSMO

was verified in the electrodeposition coating line.

stage in the middle of the measurement.

At present,

“3.1% energy-saving effect compared to the conventional method” has been obtained.

Verification of energy efficiency:

When a 7.5-kilowatt motor is operated “17 hours a day, 335 days”,

The “difference in initial cost with a three-phase motor” can be recovered in two years.

Mitsubishi Electric:

Equipment Marketing Department In the future,

we will increase production efficiency through mass production

and offer it at a lower price than three-phase motors.

MELSUSMO has great potential.

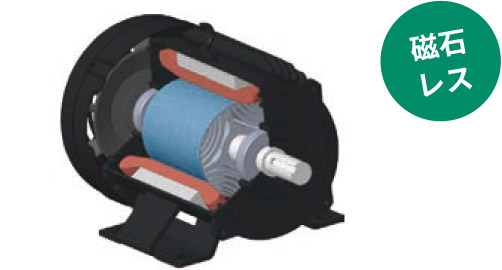

No Permanent Magnets:

A major feature of MELSUSMO is resource saving.

Unlike IPM motors, permanent magnets are not used as raw materials.

No Rare Earth Required:

At present, each country relies on specific countries such as China for rare earths,

which are raw materials for permanent magnets.

Even if the supply of rare earths stops, it will not affect motor production.

Reduction of CO2 emissions:

Replacing with synchronous reluctance motors leads to significant energy savings.

Current motors have high CO2 emissions.

Response on the sales side:

User feedback is greater than expected.

Japanese industries and companies are testing and adopting it.

Mitsubishi Electric has set a sales target of 1,000 units in FY2013.

90kw class lineup:

Until now,

the motor output was limited to 5.5-15kw.

In the future,

the lineup will be expanded to include output of 90kw class.

Production is planned at bases such as Nagoya Works and Fukuyama Works.

For inverter drive only:

MELSUSMO is only for inverter drive. At present,

MELSUSMO is limited to inverter drive only.

If inverter drives become popular in the market,

they will dominate the market.