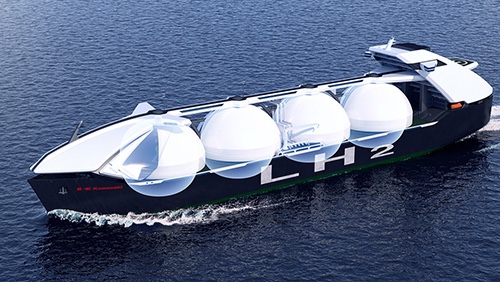

160,000 m3 liquefied hydrogen carrier (Rendering image)

Kawasaki’s large liquefied hydrogen tanker: To be equipped with a 160,000m3 tank!

ーCooling hydrogen to minus 253℃, reducing volume to 1/800 of gasー

Report from the latest article on Newswitch

Kawasaki Heavy Industries:

Completed technological development of cargo tanks for large liquefied hydrogen carriers. Aiming for commercialization in the mid-2020s.

A NEDO subsidized project designed four tanks with a capacity of 160,000m3. It was confirmed that “the thermal insulation performance can be obtained as planned.”

“Efficient replacement with inert gas and insulation performance” were confirmed in the tank.

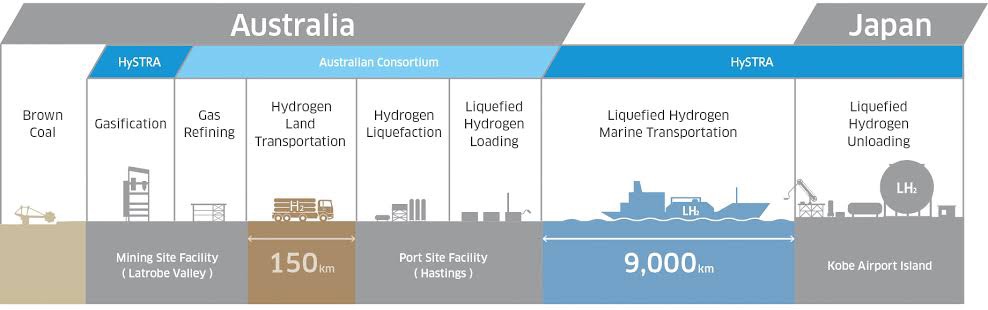

Marine Mass Transportation Supply Chain:

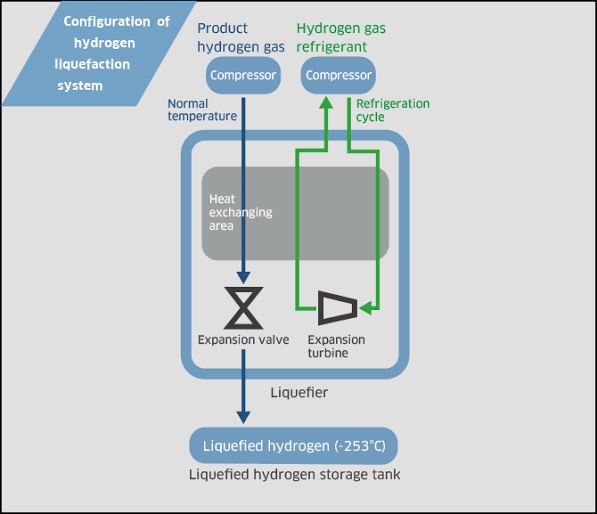

Hydrogen is cooled to minus 253 degrees Celsius, liquefied, and the volume is reduced to 1/800 of that of gas, which is planned for mass transportation by sea.

Technological Development of Cargo Tank for Large Liquefied Hydrogen Carriers Completed

Kawasaki Heavy Industries, Ltd.

NEDO*1 subsidy program “Technology Development Project for Building a Hydrogen Society,

Technology Development for Using Hydrogen Energy on a Large Scale,

Development of Large-Scale Transport and Storage Equipment

Export and Import Terminal Equipment for Liquefied Hydrogen.” In this project,

Kawasaki designed and built a test tank to be used

to verify the performance of a CCS for large liquefied hydrogen carriers, and conducted verification tests.

https://global.kawasaki.com/en/corp/newsroom/news/detail/?f=20230606_4159