APB: Ability of next-generation secondary battery: Former Nissan engineer, APB CEO Horie

APB:

Lithium-ion secondary battery:

A lithium-ion secondary battery that is indispensable as a power source for mobile devices and EVs.

Startup Company: APB

Next-generation technology, “all-resin batteries,” is drawing attention.

The work is done by APB, a startup company founded in 2018 (Tokyo: Hideaki Horie, CEO).

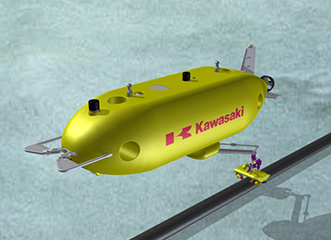

Kawasaki Heavy Industries: Installed in AUV

Kawasaki Heavy Industries decided to install it on the AUV, and its demonstration test began in July.

AUV is an unmanned submersible for maintenance and inspection of undersea equipment such as submarine cables and pipelines.

To work in water for a long time, a large capacity battery is required.

Kawasaki Heavy Industries

Larger capacity than conventional batteries,

Also has excellent water pressure resistance,

We decided to use all-resin batteries.

Three advantages of resin batteries:

Lithium-ion battery:

Charge and discharge are performed by the movement of lithium ions between the positive electrode and the negative electrode.

All resin batteries have the same charging/discharging mechanism.

All-resin battery:

While the current lithium-ion battery uses many metallic materials,

In all-resin batteries, almost all members including electrodes are molded with resin.

The active material of the positive and negative electrodes is covered with a gel-like polymer, and the current collector is made resin.

Confirmed the merits of resinification with Mr. Hideaki Horie (63), the developer of all resin batteries and CEO of APB.

There are three advantages to using resin.

The first is safety:

When a lithium-ion battery is short-circuited due to strong shock or pressure, a large current flows at once in the metal current collector.

There is a risk of overheating to over 500 degrees and leading to an accident such as a fire.

All-resin batteries are “high-safety because a resin with a large resistance is used instead of a metal member, so even if a short circuit occurs, a large current does not flow at once,” says Mr. Horie.

Second is the manufacturing cost:

Lithium-ion batteries go through about 20 manufacturing processes from material adjustment to modularization.

The manufacturing process of all resin batteries is simple and the number of steps is about half.

Third, the battery performance:

All-resin batteries have higher energy density than conventional lithium-ion batteries,

The battery capacity more than doubled can be realized.

In addition, it is easy to make the electrode thicker, and the size of the cell is larger and the flexibility of the shape is high.”

APB roadmap:

The next step is to launch a huge second factory by the mid-2020s.

At that time, a scenario is being drawn to reduce the manufacturing cost to less than half that of lithium-ion batteries.

Material/Machine/Heavy Electric | Toyo Keizai Online

https://toyokeizai.net/articles/-/373272?display=b