Aisin: Start resource recycling system!

-Generate methane gas from recovered CO2

AI Think – from Aisin disclosure materials

“Resource Recycling System”:

Aisin has started system evaluation at the Nishio Die Cast Factory (Nishio City, Aichi Prefecture).

This is a system that separates, recovers, and utilizes CO2 generated by factory equipment.

Methane gas is generated from the captured CO2 and recycled as fuel for the melting furnace.

One of the “major solutions for realizing production CN in 2035”.

Combustion equipment such as aluminum melting furnaces:

We handle many automotive parts made from aluminum, such as eAxles and transmissions.

Combustion facilities such as aluminum melting furnaces use city gas energy.

CO2 is emitted during combustion, accounting for one-fourth of the CO2 emitted from factories.

In July 2021, kick off the resource circulation system development project.

One year and nine months after the launch, we were able to start evaluating the system.

Resource recycling system that separates and utilizes CO₂

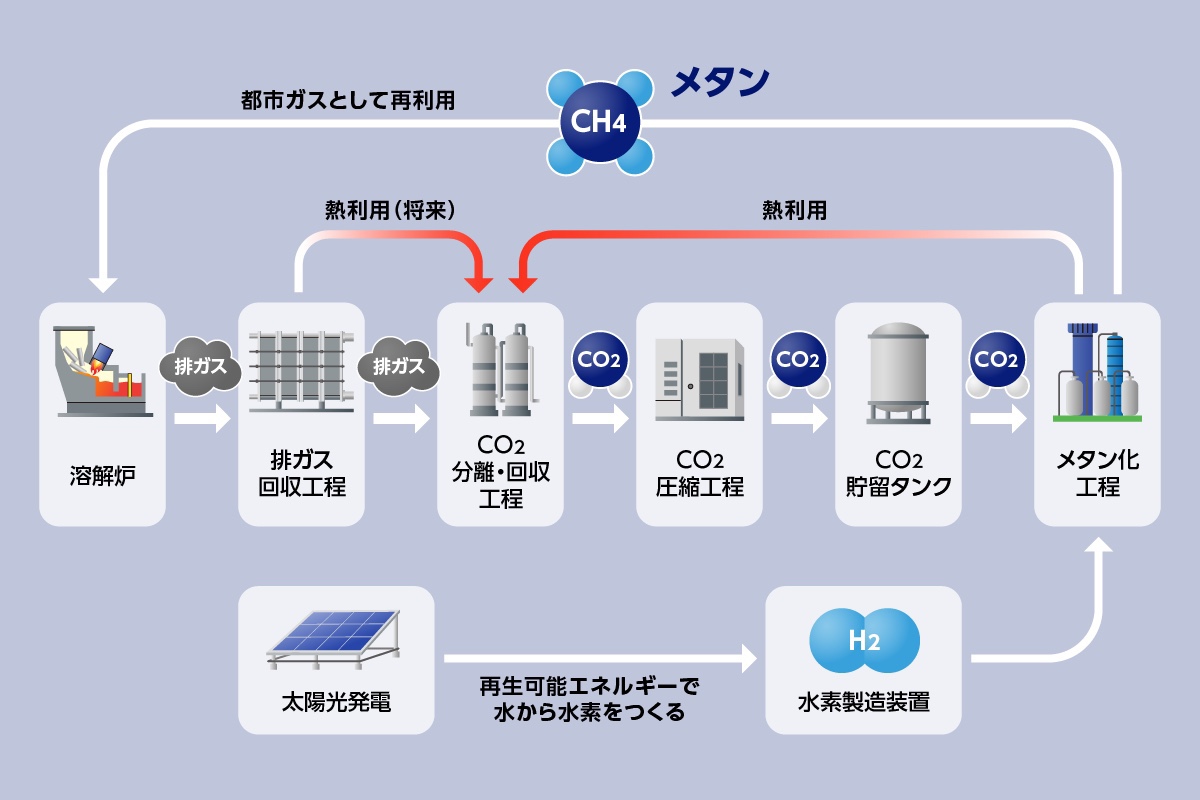

How the resource recycling system works:

It consists of a “CO2 separation process that extracts CO2” and a “methanation process that generates methane from CO2” from the exhaust gas of the factory’s combustion equipment.

Dust is removed from the high-temperature exhaust gas emitted from the aluminum melting furnace in the exhaust gas recovery process, and the exhaust gas is cooled to room temperature.

“The CO2 concentration at this stage is about 5 to 10%,” which is not high.

The CO₂ concentration is increased to 99% in the CO₂ separation process, and the high-purity CO₂ is stored in compression tanks.

In the methanation process, CO2 and hydrogen are reacted to produce methane.

The generated methane is poured into the existing gas path and reused.

The CO₂ in the exhaust gas is recovered and the methane produced is reused as fuel.

Separation and capture of CO2 using absorbents:

The key to the system is the unique CO2 separation process.

CO2 separation by “chemical absorption method”:

Aisin adopted the “chemical absorption method” that separates CO2 with an absorbent.

The chemical absorption method generally requires a large facility with a height of about 20 meters.

On the other hand, Aisin’s system is about 3 meters.

With our unique recovery mechanism and optimal absorbent, we have streamlined the separation and recovery of CO₂ and downsized the system.

Main process methanation step:

An important point is not only the generation of methane, but also the reuse of heat.

The reaction heat of CO2 and hydrogen is circulated to the CO2 separation process and used to heat the absorbent.

Exhaust heat from the melting furnace is also used in the CO2 separation process.

System CO2 capture:

The amount of CO2 collected by the current system is 0.024t-CO2/day, which is equivalent to 12 m3/day (ntp*) of methane.

This is 1/100 of the CO2 generated from one melting furnace.

In fiscal 2025, we will develop a system that recovers all the CO2 generated from one melting furnace.

https://www.aisin.com/jp/aithink/innovation/blog/005927.html