Sumitomo Chemical: Realization of recycling of acrylic resin: chemically recycled PMMA

-To contribute to reducing the environmental load-

August 23, 2021

Sumitomo Chemical:

We have decided to construct a chemical recycling demonstration facility for acrylic resin (PMMA, polymethylmethacrylate) at the Ehime Plant.

Acrylic resin recycling equipment:

Demonstration tests will begin in the fall of 2022, and samples will be available in 2011.

Established resource recycling system:

In parallel with this initiative

From the collection of used acrylic resin

From recycling of acrylic resin to commercialization

Establish a resource recycling system.

Acrylic resin:

In addition to having extremely high transparency among synthetic resins, it also has excellent weather resistance and workability.

Car tail lamp cover

Home appliances, aquariums, outdoor signboards, liquid crystal displays,

For building materials, splash prevention boards, etc.

Widely used.

Global demand in 2020 will reach 1.3 million tons.

Strong growth is expected in the future.

Established original basic technology:

Acrylic resin is thermally decomposed and regenerated as MMA monomer as a raw material.

By establishing our own basic technology, we decided to construct a demonstration facility.

Sumitomo Chemical

https://www.sumitomo-chem.co.jp/news/detail/20210823.html

Sumitomo Chemical to Construct Chemical Recycling Pilot Facility for Acrylic Resin to Reduce Impact on the Environment

Aug. 23, 2021

Sumitomo Chemical

has decided to construct a pilot facility for chemical recycling of acrylic resin (PMMA, poly-methyl-methacrylate) at its Ehime Works in Niihama City, Ehime Prefecture, Japan.

The new facility

is scheduled to begin pilot tests in the fall of 2022 and to start providing samples in 2023.

In parallel with this project,

the Company will work to develop a recycling system for PMMA, from collection of used acrylic resin to recycling and reprocessing into products,

aiming for early commercialization of chemically recycled PMMA.

Acrylic resins,

which possess the highest level of transparency among synthetic resins as well as superior weatherability and processability,

are used in a wide range of applications, such as automotive tail lamp covers, electrical appliances, aquariums, outdoor signboards, liquid crystal displays, building materials, and protective partition panels to reduce the spread of droplets.

Global demand for acrylic resins

exceeded 1.3 million tons in 2020, and is expected to continue to grow steadily in the future.

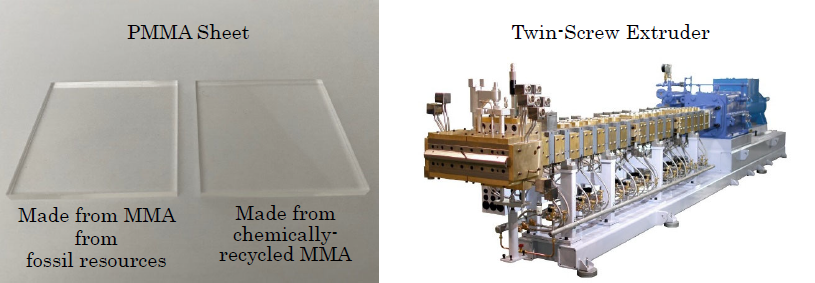

For acrylic resin chemical recycling,

the Company has been pursuing development

in collaboration with The Japan Steel Works, Ltd. combining JSW’s continuous plastic decomposition technology

using twin-screw extruders with Sumitomo Chemical’s expertise on MMA (methyl methacrylate) monomers and acrylic resins that it has cultivated over the years.

With its own basic technology to pyrolyze acrylic resin and regenerate it as MMA monomer,

which is used as a raw material, now successfully established, Sumitomo Chemical has decided to construct a pilot facility.

Business & Products | SUMITOMO CHEMICAL

https://www.sumitomo-chem.co.jp/english/news/detail/20210823e.html